CNC Drilling Services

Precision, Efficient and Reliable CNC Drilling Service Provider

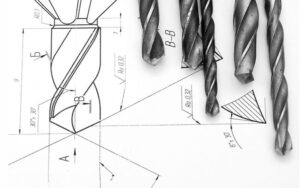

What is CNC drilling?

CNC drilling is the precise process of drilling holes in materials by controlling the motion path and machining parameters of a drilling machine using computer numerical control (CNC) technology.

This allows for efficient and accurate creation of a wide range of hole types, including round, blind, small, and deep holes, ensuring high precision and consistency in every part.

Features of CNC drilling

- High precision: the CNC system ensures drilling precision and is able to meet micron-level tolerances.

- Flexibility: Various types of holes can be processed, including blind holes, small holes and deep holes.

- High efficiency: automated processing improves productivity and is suitable for mass production.

- Complex Geometry: Not only can it drill common round holes, but it can also handle a variety of complex shaped holes.

- High Repeatability: The size and shape of each part remains consistent, ensuring high repeatability.

CNC drilling process

The process mainly includes the following steps:

Preparation stage

Generate the corresponding CNC program according to the customer's design drawings and prepare the required materials and drills.

Clamping and positioning

Fix the material on the drilling table to ensure the positioning accuracy to ensure the accurate hole position during the machining process.

CNC Drilling Processing

According to the set CNC program, the drill bit carries out cutting processing according to the predetermined path, and drills out the holes step by step.

Post processing

After completing the drilling, carry out the necessary surface treatment and accuracy check on the parts to conform to the machining accuracy.

Quality Control and Delivery

All machined parts will go through strict quality inspection and testing to ensure that all parts are delivered on time with quality and quantity.

Types of CNC Drilling Machines

In order to meet different drilling requirements, Allied Metal is equipped with several types of CNC drilling machines, each suitable for different working conditions and part characteristics:

Compact structure, suitable for drilling small workpieces, high machining precision and easy to operate.

The spindle is arranged vertically, suitable for processing small workpieces, providing high-precision hole processing.

The spindle is arranged horizontally, which is suitable for machining larger workpieces, and can be combined with a rotary table to realize multi-angle machining.

With rotatable and lifting rocker arm, it is suitable for processing in large workspace and can perform milling operation with more diverse functions.

The spindle is fixed on the gantry for machining large workpieces with high stability and strong heavy-duty capability.

Designed with table movement for excellent performance in drilling and milling, it is suitable for applications requiring high stability and versatile machining.

With rotary table for multi-surface machining of complex parts, providing higher machining flexibility.

These different types of CNC drilling machines are capable of meeting a wide range of drilling needs, from small to large workpieces, ensuring precise and efficient machining solutions for our customers.

Our CNC Drilling Services

Allied Metal offers a comprehensive range of CNC drilling services to suit a variety of industry needs. Whether it’s a single customized piece or a high volume production run, we can provide a highly accurate and efficient solution.

Multiple hole types machining

Blind holes, small holes, deep holes, slanted holes, concentric holes, ball head holes, etc.

High-precision CNC drilling

Holes up to 7 cm in diameter can be drilled to ensure compliance with customers’ precision requirements.

Multiple material adaptability

Handles a wide variety of materials such as metals, plastics, and composites for different industries.

Machining of complex geometries

We are able to handle holes with special shape requirements to meet a variety of complex design needs.

Small- and large-volume production

Whether it’s a small trial run or large-scale production, we can provide efficient and flexible production services.

Materials we can process

With our strong supply chain system, we can provide over 100 materials for you to choose from to meet your various processing needs.

Metals

We handle a wide range of metal materials such as aluminum, stainless steel, copper and titanium alloys for the aerospace, automotive, electronics and other industries, providing high precision and durable machining solutions.

Plastic

Our CNC drilling technology is also suitable for a wide range of engineering plastics, such as polycarbonate and nylon, which are widely used in the manufacture of electronic, mechanical and automotive parts.

Composites

We are capable of machining composite materials such as carbon fiber and glass fiber reinforced plastics, which are widely used in aerospace, automotive and high-performance equipment to meet the demand for lightweight and high strength.

CNC Drilled Parts Case Studies

We provide high-precision CNC drilling services for many industries, and the following are some typical examples of parts: