Materials

Aluminum parts manufacturer

CNC Machining Service | Custom aluminum parts

ISO 9001 Certified CNC Machining Supplier in China, EU Delivery 5-10 Days

- Source Factory

- Reasonable price

- Certified Materials

- Timely delivery

Aluminum Parts Machining Services

Allied Metal specializes in high quality custom machining of aluminum parts!

With over 20 years of machining experience, state-of-the-art equipment, and professional service, we provide customized aluminum part solutions for customers in a variety of industries.

Whether you need high-volume production or precise, low-volume customization! Allied Metal can meet your needs for efficient and cost-effective aluminum machining services.

Properties of Aluminum

Aluminum is a lightweight, corrosion-resistant metal that is used in a wide variety of industries, especially in the aerospace, automotive, electronics and construction industries. Key properties of aluminum include:

- Lightweight:

Aluminum’s low density makes it suitable for scenarios that require lightweight design. - Corrosion resistance:

The naturally occurring oxide film on the surface of aluminum resists corrosion, making it suitable for use in harsh environments. - Good thermal and electrical conductivity:

Aluminum has excellent performance in heat conduction and current transmission. - Easy processing:

Aluminum is easy to cut, weld and form, making it suitable for complex machining needs. - Recyclability:

Aluminum has a very high recycling value, making it an environmentally friendly choice.

Common Aluminum Parts

Aluminum is widely used in various industries due to its lightweight, corrosion resistance, excellent thermal and electrical conductivity, and ease of machining. The following are some common aluminum parts:

- Gears

- Drive shafts

- Engine casing

- Automobile Wheel Hubs

- Radiator

- Chassis Frame

- Automotive Engine Mounts

- Turbine blades

- Aluminum Body Panels

- Brake Caliper

- Shock absorber housings

- Aircraft body parts

- Power tool housings

- Electronic equipment housings

- Battery housings

- Water pump housings

- Heat exchanger parts

- Robotic arm parts

- Lock parts

- Aluminum Hardware Parts

Case Study: Aluminum Machined Parts

High-precision aluminum CNC machining services for prototypes and production. Fast lead times, tight tolerances, and ISO-certified quality.

Aerospace Mounting Bracket

Craftsmanship: 5-Axis CNC Milling

Material: Aluminum 7075-T6

Surface: Clear Anodized (Type II)

Tolerance: ±0.005mm

Dimension: 120mm x 85mm x 40mm

Application: Avionics & Drone Frames

Services: OEM or ODM available.

High-Performance Heatsink

Craftsmanship: CNC Milling

Material: Aluminum 6061-T6

Surface: Black Anodized

Tolerance: ±0.05mm (Fin dimensions)

Dimension: 150mm x 150mm x 50mm

Application: Power Supplies, LED Lighting

Services: OEM or ODM available.

Medical Device Enclosure

Craftsmanship: CNC Milling & Turning

Material: Aluminum 6063

Surface: White Anodized, Laser Etched

Tolerance: ±0.01mm (Fin dimensions)

Dimension: 200mm x 100mm x 60mm

Application: Diagnostic Equipment, Lab Tools

Services: OEM or ODM available.

Automotive Turbo Impeller

Craftsmanship: 5-Axis CNC Milling

Material: Forged Aluminum 2618

Surface: As Machined, Dynamic Balancing

Tolerance: ±0.01mm (Blade profile)

Dimension: Ø75mm (Exducer)

Application: Performance Turbochargers

Services: OEM or ODM available.

Robotic Arm Joint

Craftsmanship: CNC Turn-Mill Machining

Material: Aluminum 7075

Surface: Hardcoat Anodized (Type III)

Tolerance: ±0.008mm (Bearing fit)

Dimension: Ø90mm x 65mm

Application: Industrial Automation, Robotics

Services: OEM or ODM available.

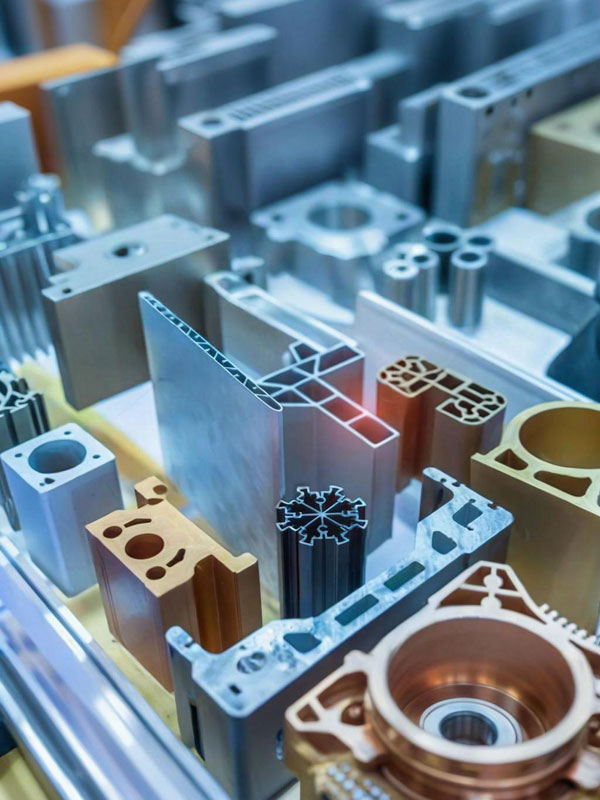

Common Types of Aluminum Fabrication Materials

Material Type | Characteristics | Common Grades | Applications |

Cast Aluminum Alloys | Good fluidity, suitable for casting into complex shapes; often contains silicon for improved fluidity and corrosion resistance | A356, A380, A390 | Automotive parts, housings, aerospace components |

Wrought Aluminum Alloys | Suitable for rolling, extrusion, forging; generally has good strength and ductility | 1050, 1060, 2024, 3003, 5052, 6061, 7075 | Construction materials, aerospace, vehicle components, structural parts |

Aluminum Foils and Sheets | Thin and lightweight, suitable for packaging and decorative materials; aluminum foil is up to 0.2mm thick | Foil: up to 0.2mm | Food and pharmaceutical packaging, architectural decor, heat exchangers |

Aluminum Rods and Tubes | Available in shapes such as round bars, square bars, round tubes, and square tubes; ideal for structural support or fluid passage | Construction supports, frames, piping systems, furniture, transportation | |

Aluminum Profiles | Extruded shapes with complex cross-sections, high strength, corrosion resistance, suitable for high-precision frameworks | Building doors and windows, curtain walls, heat sinks, industrial frames and rails | |

Aluminum Powders and Granules | Small granules, suitable for powder metallurgy and additive manufacturing (3D printing) | 3D printing materials, rocket propellants, chemical reaction additives | |

High Strength Aluminum Alloys | Very high strength and hardness, suitable for high-load, high-stress applications | 7075, 7050 | Aerospace, military equipment, sporting goods |

Corrosion Resistant Aluminum Alloys | Excellent corrosion resistance, suitable for humid or corrosive environments | 5052, 5083, 6061 | Marine parts, chemical equipment, outdoor structures |

Aluminum Honeycomb Panels | Lightweight and high-strength with stable structure, commonly used in composite sandwich structures | Aerospace, architectural decor, vehicle interiors |

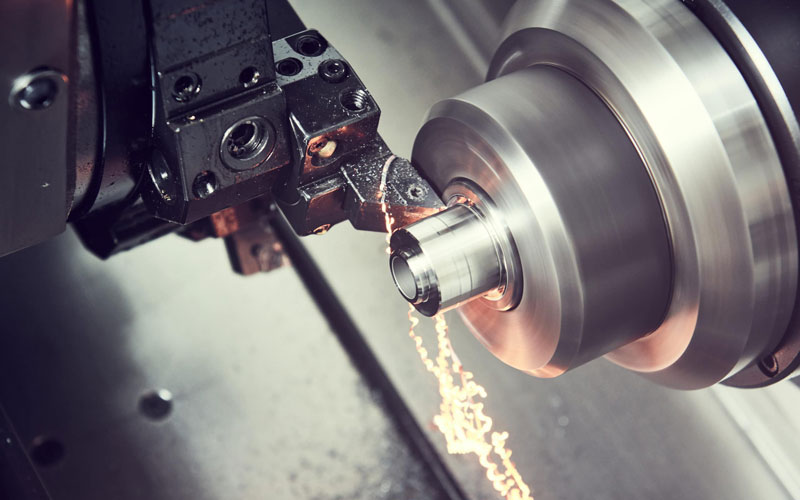

Common Aluminum Parts Machining Methods

Surface Treatment of Aluminum Parts

Through surface treatment, the corrosion resistance, hardness, appearance and performance of aluminum parts can be enhanced to make them more adaptable to harsh working environments.

The following are common surface treatment processes for aluminum parts:

Cleaning is an important step in removing machining residues (e.g., oil, cutting fluids) from the surface of aluminum parts to provide a clean surface for subsequent coating treatments.

- Benefits: Removes contaminants and improves coating adhesion.

- Applications: All aluminum parts.

Anodizing forms a strong oxide film on the surface of aluminum through electrochemical reaction, which enhances its corrosion resistance, hardness and aesthetics. The process also allows for color dyeing, adding a different appearance to the product.

- Benefits: Improves corrosion and wear resistance; available in a wide range of colors; maintains the lightweight nature of aluminum.

- Applications: aerospace, automotive, electronic equipment housings, etc.

Electroplating is the electrolytic deposition of a layer of metal (e.g., nickel, copper) onto the surface of aluminum to provide additional protection and improve wear resistance and aesthetics.

- Advantages: Enhanced wear resistance and glossy appearance; improved electrical conductivity.

- Applications: electronic equipment, decorative parts, etc.

Painting is the formation of a protective layer on the surface of aluminum by spraying coatings to provide color, luster, and corrosion resistance. Commonly used coating materials include polyester and fluorocarbon.

- Advantages: Enhances appearance, corrosion resistance, and UV resistance.

- Applications: construction, home appliances, furniture, etc.

Phosphating treatment forms a phosphate film on the aluminum surface through a chemical reaction, improving corrosion resistance and providing better adhesion to the coating.

- Advantages: Enhances corrosion resistance and improves coating adhesion.

- Applications: automobile parts, mechanical equipment, etc.

Chemical Plating is a currentless plating method that deposits metals (e.g., nickel, copper) on the surface of aluminum parts through a chemical reaction, and is suitable for parts with complex shapes.

- Advantages: Uniform metal plating, improved corrosion resistance, suitable for complex shapes.

- Applications: electronics, aerospace, automotive, etc.

Deburring is the removal of burrs generated during the machining of aluminum parts to ensure a smooth surface of the parts and prevent the impact on assembly and usability.

- Advantages: Improve surface smoothness and assembly accuracy.

- Applications: precision machinery, electronic equipment, etc.

Aluminum Parts Machining Methods Comparison:

Machining Method | Features | Applications | Tolerances | Surface Finish | Cost |

CNC Turning | Ideal for cylindrical parts, high precision, efficient production | Mechanical parts, automotive components | ±0.01 mm | Smooth (Ra 0.8-1.6 µm) | Medium |

CNC Milling | Multi-axis machining for complex geometries | Aerospace, molds, mechanical components | ±0.01 mm | High quality (Ra 0.8-3.2 µm) | Medium |

3D Printing | Layer-by-layer manufacturing, suitable for prototypes and complex parts | Prototypes, complex geometries | ±0.01 mm | Adjustable, rough to smooth | Low to medium |

Rapid Prototyping | Quick production for testing and prototyping | Design iterations, test samples | ±0.01 mm | Variable | Low |

Sheet Metal Fabrication | Suitable for large, thin parts with bending and cutting | Enclosures, brackets, panels | ±0.5 mm | Variable | Low |

Casting | Mass production of complex shapes, suitable for durable parts | Engine housings, mechanical components | ±0.01 mm | Medium (Ra 6.3-12.5 µm) | Low |

Brief Explanation of Cost Comparison:

- CNC Turning and CNC Milling:

High precision, moderate cost, suitable for high-demand precision machining. - 3D Printing:

Ideal for small batch production and complex parts, low upfront cost but higher for mass production. - Rapid Prototyping:

Lowest cost, ideal for quickly validating design concepts and prototypes. - Sheet Metal Fabrication:

Good for large-sized or thin parts, lower cost, efficient for mass production. - Casting:

Best for large quantities and complex shapes, lowest per-unit cost, though initial tooling can be expensive.

- CNC Turning and CNC Milling:

This comparison helps you choose the most suitable machining method based on your project’s requirements and optimize your costs accordingly.

Materials

100+ materials can be freely selected to meet your customized processing needs!

Metals

Metallic materials are rugged and offer excellent strength and durability.

Plastics

Lightweight and flexible, used in a wide range of industries.

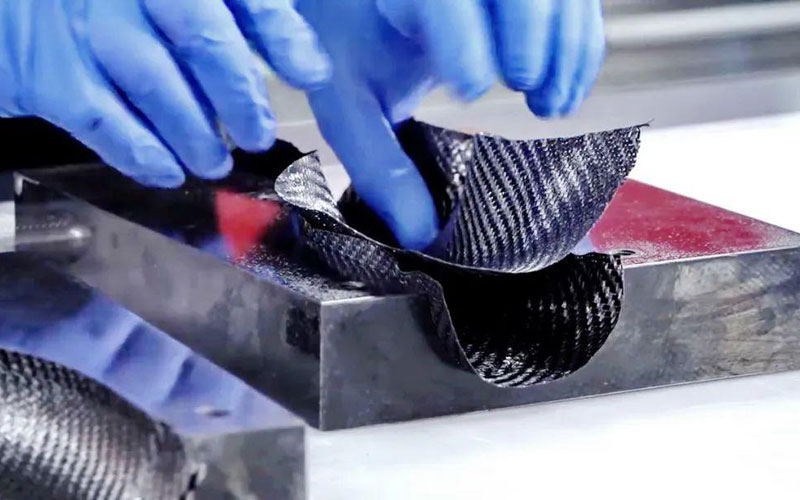

Composites

High-performance materials that combine strength and lightweight.

Why choose Allied Metal for aluminum parts machining?

Professional technical support is available at every step from design to production to ensure smooth processing.

Equipped with advanced CNC machine tools and other equipment for cast iron parts of various complex shapes and accuracy requirements.

We leverage a robust supply chain and global partnerships to provide high-quality, customized materials for all projects.

We tailor processes to optimize cost, materials, and performance, ensuring efficient, high-quality delivery for any batch size.

When choosing an aluminum material, you need to consider its application area, strength, corrosion resistance and processing difficulty. Our team of experts will help you choose the most suitable aluminum alloy material according to your needs.

Yes, we offer flexible small-lot customization services. Whether it is for sample development or small-scale production, we can provide high-quality aluminum parts.

Delivery time depends on the complexity and lot size of the part. We will confirm the delivery time with you at the beginning of the project and make sure it is on time.

We offer a variety of surface treatments, such as anodizing and painting, which can effectively enhance the corrosion resistance and aesthetics of the parts.