CNC milling is a machining technology that utilizes computer control to accurately cut a variety of materials in order to manufacture complex parts and products.

Because CNC milling machines can move in multiple axes, CNC milling with 3-axis or 5-axis machines can produce extremely complex geometries and part features with unparalleled precision.

CNC Milling Service

Allied Metal offers CNC milling services for custom parts in any material and specification.

From simple lines to complex shapes, we deliver fast and precise designs.

What is CNC milling?

Features and advantages of CNC milling

- High precision: able to achieve very high machining accuracy, ensuring that the size of the part meets the requirements.

- Automation: reduce manual operation and improve production efficiency.

- Flexibility: Especially suitable for small-lot, multi-variety production needs.

- Complex shapes: capable of machining complex geometries and details.

The Materials Of CNC Milling

CNC milling parts can be used on almost any solid material that is strong enough to hold its shape while being milled. This can include some types of glass, plastic, and metal, especially for CNC milling aluminum or milling stainless steel.

Here are some of the most commonly-used CNC metals.

Aluminum

Brass/bronze

Copper

Titanium

Nickel

Zinc

Steel/steel alloys

Many types of plastic are also used in custom cnc milling, including:

Acrylic

ABS

Polypropylene

Polyvinyl chloride (PVC)

HDPE

Polycarbonate

PET

Surface Finishes for CNC Milling

There are a wide variety of different surface finishes available at the Allied facility. Here are a few different available CNC milling surface finishes which may be appropriate for your parts.

Aluminum

Anodizing, Bead blasting, Powder Coating, Electroplating, Polishing, Brushing, Painting

Plastic

Brushing, Bead blasting,Sanding, polishing, spraying, silkscreen, pad printing, heat transfer, water transfer, laser engraving

Other Metals

Bead blasting, Powder Coating, Electroplating, Polishing, Brushing, Painting

CNC Milling Tolerance

AT Allied Metal, we use the latest 3 and 5-axis CNC machines that offer high precision and accuracy, and ensure tight tolerances for all of our machined parts. Our standard milling tolerances are:

- 300mm (12”) part size – Tolerances of ± 0.125mm (0.05”), angularity of ± 0.5°

- 600mm (24”) part size – Tolerances of ± 0.250 mm (0.10”), angularity of ± 1.0°

- 900mm (36”) part size – Tolerances of ± 0.400 mm (0.15625”), angularity of ± 1.0°

It is possible for us to produce parts with tolerances as low as ± 0.020mm (.0008”). Any tolerance tighter than this will require a consultation with our technical team.

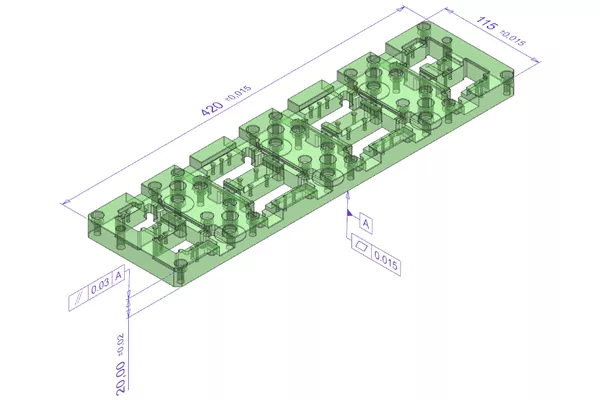

CNC milled parts we have machined

We provide CNC milling services to a wide range of industries, producing parts ranging from precision machine parts, mold parts, automotive parts, and aerospace components to meet the needs of a variety of customers.

Why chooes CNC Milling?

CNC milling is perfect for creating complex shapes like angles, slots, holes, and curves. It offers quick turnaround times, with parts made in minutes, unlike traditional methods like injection molding, which can take days or even weeks.

CNC milling works with a wide variety of materials, including metals, plastics, and composites, making it more versatile than 3D printing, which is limited to certain plastics and metals.

Choose CNC milling for parts with superior surface finishes, as it allows for options like painting, chroming, and anodizing.

FAQ

We support small quantity and large quantity production, the specific quantity can be negotiated according to the project requirements.

The delivery lead time depends on the machining difficulty and quantity, usually within 1-4 weeks.

Yes, we provide sample processing service for customers to test and verify.

Please contact our sales team with your design documents and requirements, we will provide you with a quotation as soon as possible.

Or send us the drawing and requirements directly, we will contact you for a quote in the fastest time possible, e-mail address: quote@alliedcn.com

– **3-axis milling**: moves in X, Y and Z directions only, suitable for simple shapes.

– **4-Axis Milling**: Adds a rotary axis to the 3-axis, enabling the machining of more complex geometries and is suitable for parts that require additional angles.

– **5-axis milling**: Simultaneous control of 5 axes enables more complex cutting paths, suitable for machining complex shapes and parts requiring high precision, reducing the number of workpiece clamping.