1. Overview

1.1 What is Surface Roughness?

Surface roughness refers to the small, uneven peaks and valleys on a machined surface, with very short distances between them (typically less than 1mm). It is considered a micro-geometric error. The lower the surface roughness, the smoother the surface.

1.2 Measuring Surface Roughness

Measured using height, spacing, and composite parameters.

The most common height parameter is the average arithmetic deviation (Ra), which is the average distance between the surface contour and its centerline.

Surface roughness affects the fit, wear resistance, fatigue strength, contact stiffness, vibration, and noise of mechanical parts, influencing the lifespan and reliability of products.

2. Surface Roughness vs. Finish Grade Comparison

Roughness Parameter (Ra) | Surface Finish Grade | Surface Features | Processing Methods |

Ra 0.012 - 0.025 | 14 | Mirror-like Gloss | Superfine grinding, polishing, super finishing, mirror finish |

Ra 0.025 - 0.05 | 13 | High Gloss | Fine grinding, polishing, super finishing |

Ra 0.05 - 0.1 | 12 | Glossy Surface | Precision turning, precision grinding, fine surface grinding |

Ra 0.1 - 0.2 | 11 | Matte Mirror | Grinding, precision turning with diamond tools, precision grinding |

Ra 0.2 - 0.4 | 10 | Slightly Visible Marks | Grinding, polishing, cold drawing |

Ra 0.4 - 0.8 | 9 | Visible Marks | Grinding, polishing, cold drawing |

Ra 0.8 - 1.6 | 8 | Noticeable Tool Marks | Rough grinding, rough turning, rough milling, rough planing |

Ra 1.6 - 3.2 | 7 | Visible Machining Marks | Rough turning, rough milling, rough planing, drilling |

Ra 3.2 - 6.3 | 6 | Slightly Visible Machining Marks | Rough turning, rough milling, rough planing |

Ra 6.3 - 12.5 | 5 | Distinct Machining Marks | Rough turning, rough milling, rough planing |

Ra 12.5 - 25 | 4 | Noticeable Tool Marks | Turning, boring, planing |

Ra 25 - 50 | 3 | Distinct Machining Marks | Turning, boring, planing |

Ra 50 - 100 | 2 | Rough Surface | Rough turning, rough milling, rough planing |

Ra > 100 | 1 | Extremely Rough Surface | Rough machining, casting, forging |

PS: Different techniques can be used during the machining of the part depending on the Ra value to obtain the desired surface finish.

3. Surface Roughness Comparison: China vs. U.S.

China Old Standard (Ra) | New China Standard (Ra) | U.S. Standard (Microns) | U.S. Standard (Microinches) |

▽4 | 6.3 | 6.3 | 8.00 |

▽5 | 3.2 | 3.2 | 5.00 |

▽6 | 1.6 | 1.6 | 2.50 |

▽7 | 0.8 | 0.8 | 1.25 |

▽8 | 0.4 | 0.4 | 0.63 |

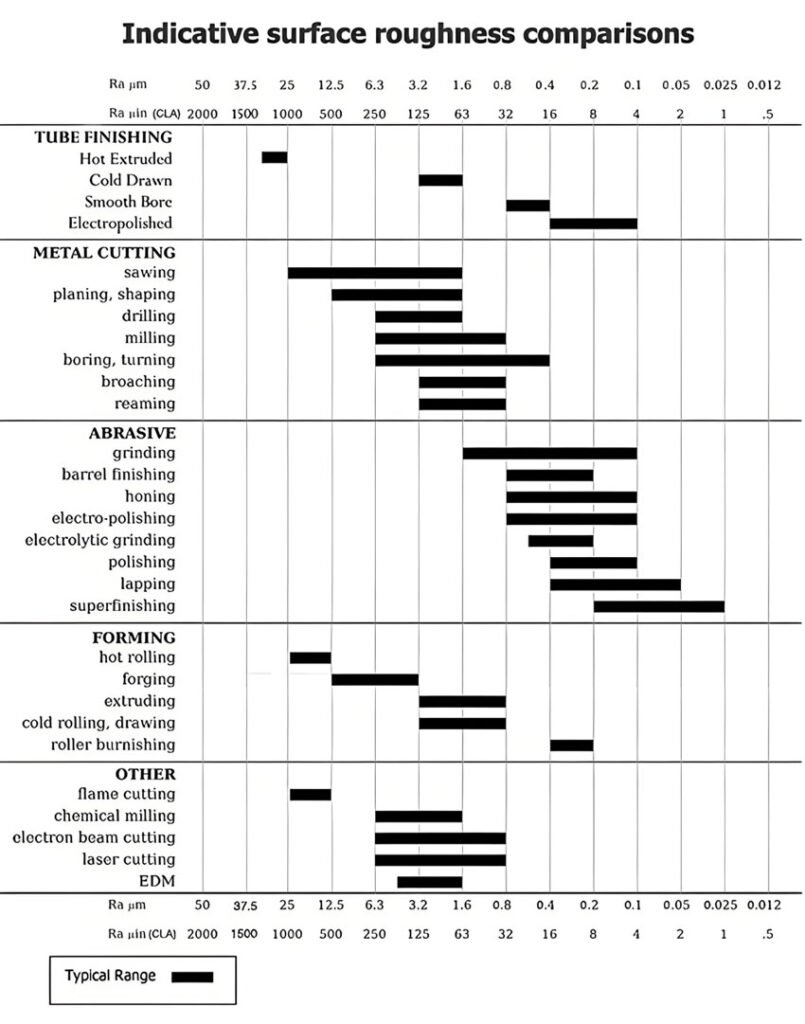

4. Surface finish roughness for different manufacturing processes

I like this post, enjoyed this one appreciate it for putting up.

Does your website have a contact page? I’m having trouble locating it but, I’d like to shoot you an e-mail. I’ve got some suggestions for your blog you might be interested in hearing. Either way, great blog and I look forward to seeing it expand over time.