Table of Contents:

CNC machining and electric vehicle manufacturing: the perfect blend of innovation and efficiency

- January 17, 2025

- Tony

In the field of electric vehicle (EV) manufacturing, technological advances continue to drive the industry forward. As the demand for efficient and precise components increases, CNC machining (CNC) has become one of the key technologies in EV production.

1. The role of CNC machining in the electric vehicle industry

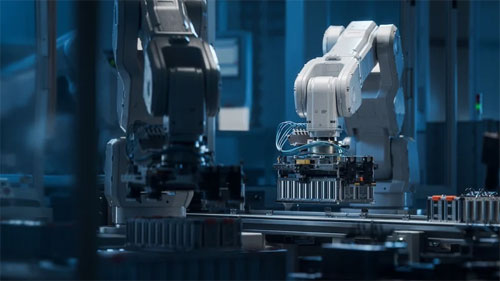

CNC machining is crucial in modern manufacturing, enabling the production of precision components using automated machinery. In electric vehicle (EV) production, CNC machining ensures the high precision and complexity required for key components, like battery shells and drive systems, maintaining consistency and accuracy throughout the process.

Precision and Efficiency: CNC machining advantages

CNC machining excels in precision, essential for EV components with complex designs that are challenging for traditional methods. It achieves micron-level precision, ensuring parts meet stringent standards for size, shape, and surface quality.

Additionally, CNC automation boosts productivity by reducing human error and enabling continuous operation, which is vital for high-volume EV production.

CNC machining meeting high standards in electric vehicle manufacturing

EV manufacturing demands high-quality components, especially in drive systems, power batteries, and lightweight structures. These parts must meet strength, durability, and weight requirements to optimize energy efficiency and range. CNC machining is the ideal solution for meeting these rigorous standards.

2. Critical components in the manufacture of electric vehicles

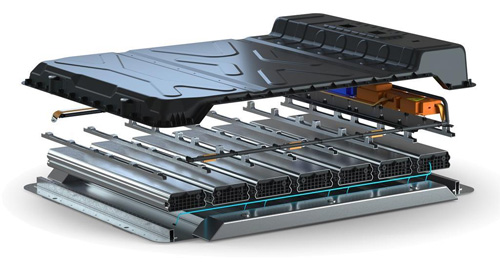

The core components of an electric vehicle, such as the battery casing, electric drive system, and heat dissipation system, require advanced processes like CNC machining to ensure efficiency and performance.

Electric Vehicle Battery Housing and Electric Drive System

Battery housings need to be strong to protect cells while being lightweight to reduce the vehicle’s overall weight. CNC machining ensures precise, complex designs, maintaining strength and hermeticity to meet safety standards.

The electric drive system, which includes motors and drive shafts, relies on CNC machining for high precision and durability, ensuring optimal performance, reducing mechanical failures, and minimizing energy losses.

Lightweight EV Parts and High-Performance Materials

As demand for longer range grows, reducing weight becomes crucial. CNC machining produces complex lightweight components, like body frames, without sacrificing strength. It’s also used to work with high-performance materials (e.g., aluminum alloys, carbon fiber composites), improving performance and energy efficiency.

Heat Dissipation Systems and Precision Machining

The battery and drive systems generate significant heat, making effective heat dissipation essential. CNC machining enables precise fabrication of parts like radiators and cooling lines, ensuring efficient heat management and enhancing safety and durability.

3. Integration of CNC machining with electric vehicle manufacturing

CNC machining not only improves manufacturing accuracy but also helps manufacturers reduce costs and increase production speed through a more efficient production process.

CNC Machining in Electric Vehicle Structural Components

The structural parts of electric vehicles usually involve large sizes and complex shapes. CNC machining technology, through the precise operation of CNC machine tools, can process structural parts such as body frames and chassis to meet the requirements and ensure their performance in terms of load bearing and collision.

Impact of precision machining on the performance of electric vehicles

The performance of electric vehicles depends on the precision cooperation of multiple parts, and the dimensional deviation of any one part may affect the overall performance. CNC machining can ensure the size, shape, surface quality, and fit precision of all parts, thus ensuring the power performance and safety of electric vehicles.

Improve productivity and reduce costs

Traditional manual machining methods are not only inefficient but also susceptible to human factors, resulting in longer production cycles. CNC machining, on the other hand, is capable of 24/7 production through automated operations, reducing labor costs and production time, greatly improving production efficiency, and helping manufacturers maintain an edge in the highly competitive EV market.

4. Challenges and Opportunities: Innovative Applications of CNC Machining in Electric Vehicles

Machining challenges for high-strength materials

Many of the high-strength materials (e.g. titanium alloys, carbon fiber composites, etc.) that electric vehicles need to use are difficult to machine. However, as CNC machining technology continues to advance, the precision and efficiency of machining these materials are gradually improving, and CNC machining manufacturers have been able to break through this challenge.

How does CNC technology support the rapid development of electric vehicles?

With the rapid development of the electric vehicle market, the demand for customization of parts is also gradually increasing. CNC machining can respond quickly to these demands and provide efficient production services. By flexibly adjusting equipment settings, CNC machining can adapt to the changing needs and technological advances in electric vehicle production.

5. Allied Metal's CNC Machining Solutions for Electric Vehicle Manufacturing

Allied Metal has a proven track record of delivering successful CNC machining solutions for electric vehicle manufacturing, backed by our advanced technology.

Our Technology and Service Advantages

We offer comprehensive CNC machining services for various EV components, from lightweight body parts to high-strength battery housings. Our state-of-the-art equipment handles various materials, ensuring that each element meets the rigorous standards required in EV production.

Customer Success Stories

Having partnered with numerous EV manufacturers, Allied Metal has supplied tens of thousands of precision parts. These collaborations have helped our clients boost productivity, reduce costs, and achieve superior performance in their electric vehicles.

6. Future Outlook: The Long-Term Impact of CNC Machining on Electric Vehicle Manufacturing

As the electric vehicle industry develops, the demand for CNC machining technology will increase further. The future of CNC technology will be more intelligent, able to respond more quickly to changes in market demand, and continue to make breakthroughs in material processing, precision control and other aspects.

The future trend of CNC technology

With the advent of the Industry 4.0 era, CNC machining will gradually be combined with artificial intelligence, the Internet of Things and other technologies to realize a more efficient and flexible production process. EV manufacturers will be able to customize parts more accurately and significantly improve production efficiency.

Increased demand for customized parts in the EV industry

The demand for customized parts in the EV industry will continue to increase in the future, and CNC machining will play an important role in meeting these demands.

7. Summary

CNC machining technology plays an increasingly important role in the manufacture of electric vehicles, which not only improves manufacturing accuracy and production efficiency, but also promotes the development of the entire industry.

As technology continues to innovate, CNC machining will have an even greater impact on EV production. By optimizing processes and improving capabilities, it will bring both new opportunities and challenges to the EV industry.