What is Ultra-Precision Machining?

- January 21, 2025

- Tony

1. What is ultra-precision machining?

Definition of Ultra-Precision Machining

Definition:

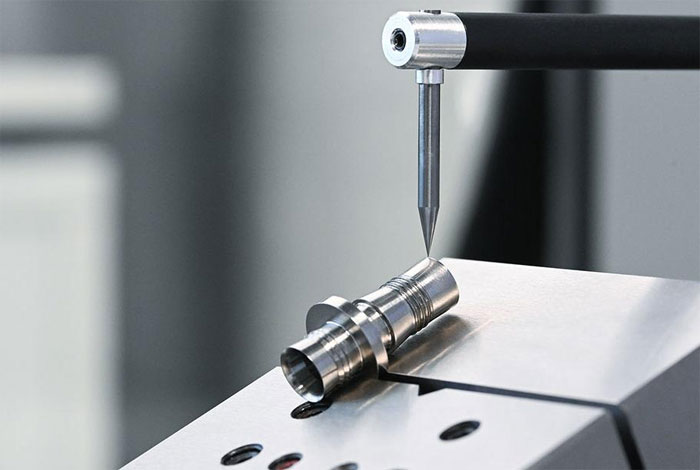

Ultra-precision machining is a high-accuracy process capable of achieving micron or even nanometer-level precision. It is used for parts requiring extreme accuracy, smooth surfaces, and defect-free finishes.

This method is commonly applied in fields like optics, aerospace, and semiconductor manufacturing, where precision often exceeds the capabilities of traditional machining.

Basic Principles:

Advanced control technology is the core of ultra-precision machining. A high-precision CNC system ensures precise tool path control, minimizing errors through rigid machine tools and special cutting tools. This process also demands careful management of cutting forces and temperatures to prevent thermal deformation and vibrations.

Key Technologies:

- Nanoscale Cutting Technology: Enables cutting at the nanometer level for superior surface finish and accuracy.

- Laser-Assisted and Electrolytic Machining: Laser assistance reduces cutting forces, improving accuracy, while electrolytic machining uses electric current to control material removal, avoiding thermal deformation.

- Ultra-Precision Grinding: Combines high-precision grinding with special fluids to enhance surface quality and reduce tool wear.

2. Comparison between ultra-precision machining and traditional machining methods

Ultra-Precision Machining

- Precision: Achieves nanometer-level precision

- Machining Efficiency: Longer processing time for higher accuracy

- Cost: Higher cost due to advanced equipment and technology

- Applications: Suitable for high-precision and high-surface-quality needs

Conventional Machining

- Precision: Generally limited to micron-level precision

- Machining Efficiency: Faster processing time with lower precision

- Cost: Lower cost with simpler equipment

- Applications: Suitable for general manufacturing and low-precision parts

3. Application areas of ultra-precision machining

Optical Industry

Ultra-precision machining is crucial for manufacturing optical components like lenses and mirrors. Even tiny errors can impact optical performance, so this technology ensures high quality and accuracy.

Semiconductor Industry

The semiconductor industry demands extreme machining precision. Ultra-precision processing is essential for manufacturing semiconductor chips, achieving micron or nanometer-scale accuracy to enhance chip performance and reliability.

Aerospace and Precision Machinery

In aerospace, component precision is critical to safety and performance. Ultra-precision processing ensures the high accuracy and reliability of parts in extreme conditions, and is also widely used in high-precision machinery.

4. Challenges in Ultra-precision Machining

- Tool Wear and Thermal Deformation:

High temperatures during machining can cause tool wear and thermal deformation of the workpiece. Controlling cutting temperatures and replacing tools on time is crucial for maintaining accuracy. - Stability of Micro-Sized Parts:

Micro-sized parts are sensitive to external factors like vibration and environmental changes. Achieving accuracy often requires precise dynamic adjustments of the machine tool and strict environmental control. - Material Selection and Machining Difficulty:

Different materials present unique challenges. For example, ceramics are hard but brittle, while metals are easier to machine but prone to thermal deformation. Material selection must balance precision needs with machining difficulty.

5. FAQ

How to Ensure Stable Machining Accuracy?

Use high-precision CNC systems and rigid machine tools, optimize tool and cutting parameters, and regularly inspect and calibrate equipment to maintain a stable machining environment.

How to Avoid Thermal Deformation?

An efficient coolant system, controlled cutting speed, and force help reduces the temperature in the cutting zone. Real-time temperature monitoring minimizes the impact of thermal deformation on accuracy.

How Does Tool Wear Affect Quality?

Tool wear can change cutting forces, leading to inaccurate machining, increased surface roughness, and dimensional errors. Timely tool replacement and monitoring are essential for maintaining high precision.

What Are the Difficulties in Machining Micro-Sized Parts?

Micro-sized parts require high machine stability, as even small vibrations or environmental changes can affect precision. Precision equipment and strict environmental control are necessary to ensure accuracy.

How to Choose Materials for Ultra-Precision Machining?

Material selection should consider hardness, thermal expansion, and stability. Common materials like cemented carbide, ceramics, and quartz offer varying machining difficulties and precision needs.

Why Choose Allied Metal for Ultra-Precision Machining?

Allied Metal has the expertise, advanced equipment, and strict quality control processes to deliver ultra-precision machining with exceptional accuracy and reliability, ensuring high-quality results for your most demanding projects.

6. Future Trends: Innovative Developments in CNC Ultra-Precision Machining

Digitalization and Intelligent Technologies

CNC ultra-precision machining is advancing with digital and intelligent technologies. Digital twin technology, AI, and machine learning will allow real-time adjustments and optimization of machining parameters, enhancing efficiency and precision.

AI in CNC Machining Optimization

AI can analyze machining data, adjust CNC parameters in real-time, and improve accuracy while minimizing manual intervention, boosting productivity.

New Materials and CNC Ultra-Precision Machining

The development of new materials, like lightweight alloys and carbon fiber composites, presents both challenges and opportunities for CNC ultra-precision machining, driving technological innovation.

7. Summary

Ultra-precision machining is a crucial technology in modern manufacturing, with its high accuracy and surface quality requirements playing a key role in a wide range of industries. From optics and semiconductors to aerospace, ultra-precision parts machining continues to drive technological advances.

While challenges like tool wear and thermal deformation remain, emerging technologies will make Ultra-precision parts machining smarter and more accurate, driving innovation across industries.