Editor's Note: Last updated on 2025-10-17 16:39:29 Friday

Finding the right CNC machining partner in China feels tough. You worry about quality, communication, and getting ripped off. This uncertainty can stop you from accessing great manufacturing options.

To find reliable CNC machining suppliers in China, look for companies with strong track records, ISO certifications, and positive customer feedback. Always verify their capabilities, ask for samples, and check their business credentials before committing to an order.

Choosing a supplier is a big decision. I've been in the CNC business for years, starting on the shop floor and later building my own company. I've learned a lot about working with Chinese manufacturers. Let me share some practical steps to help you find a dependable partner you can trust. It takes some effort, but finding the right fit is key to your project's success.

How Do I Find Reliable Manufacturers in China?

Are you worried about getting low-quality parts or dealing with dishonest suppliers in China? This fear keeps many potential buyers away. But you can find excellent, trustworthy manufacturers if you know how to look.

Start your search on platforms like Alibaba, but don't stop there. Use trade shows, ask for referrals, and most importantly, verify every potential supplier's credentials and capabilities thoroughly. Due diligence is essential.

Finding a good supplier isn't just about searching online listings. You need to dig deeper to make sure they are legitimate and capable. When I first started sourcing, I learned quickly that verification is critical.

Key Verification Steps:

- Business License: Check registration details, business scope, and legal representative.

- Factory Audit (Optional but Recommended): Visit in person or hire a third-party service.

- References & Reviews: Ask for customer references and check online reviews.

- Sample Orders: Place a small trial order to test quality and service.

| Verification Area | What to Check | Why it Matters |

|---|---|---|

| Registration | Valid business license, registered capital1 | Confirms legal existence & stability |

| Capabilities | Machine list, staff skills, QC process | Ensures they can meet your needs |

| Certifications | ISO 90012, industry-specific certs | Shows commitment to quality standards |

| Communication | English proficiency, response time | Crucial for smooth collaboration |

| Reputation | Customer reviews, industry standing | Indicates reliability and trust |

Red Flags I've Learned to Spot Over the Years

After evaluating hundreds of Chinese suppliers, here are the warning signs that immediately make me cautious:

1. The "Yes-Man" Syndrome

Beware of suppliers who agree to everything without asking technical questions. A good supplier will:

- Ask about critical tolerances and surface finish requirements

- Question design features that might be difficult to machine

- Suggest design improvements for manufacturability

- Be honest about their limitations

2. Unrealistic Lead Times

If a supplier promises 5-day delivery on complex parts when others quote 3 weeks, they're either:

- Overpromising and will likely miss deadlines

- Cutting corners on quality control

- Not understanding the complexity of your requirements

3. Vague Quality Control Processes

When I ask "How do you inspect parts?" and get answers like:

- "We have experienced workers check them" (no specific procedures)

- "We do 100% visual inspection" (no measurement data)

- "We can provide inspection reports" (but can't specify what measurements they take)

4. Pricing That's Too Good to Be True

A quote 40% lower than other reputable suppliers usually means:

- Inferior materials (domestic vs imported)

- Older, less precise equipment

- Limited quality control

- Hidden costs that appear later

How Much Does CNC Machining Cost in China?

You might think that lower prices in China automatically mean lower quality. That's a common concern. But understanding how pricing works helps you find good value without sacrificing quality.

CNC machining in China is often 30-50% cheaper than in Western countries. Costs depend heavily on part complexity, material, quantity, and tolerances. Expect clear, itemized quotes from reliable suppliers.

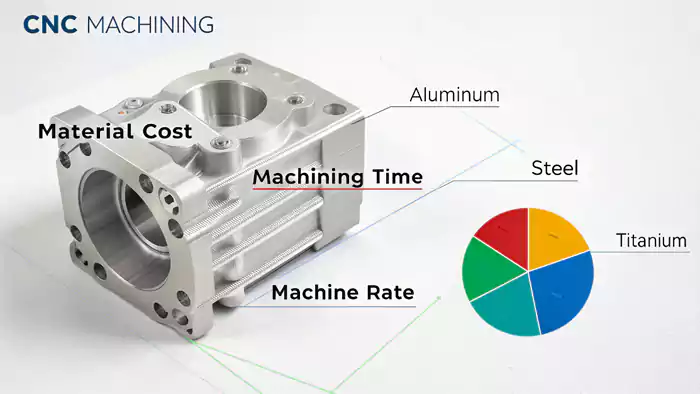

Getting a low price feels good, but it isn't the whole story. I always tell my clients to look at the total cost. This includes the part price, shipping, import duties, and any potential costs from quality issues or delays. A slightly higher price from a proven, reliable supplier is often cheaper in the long run. Good suppliers provide detailed quotes. These quotes should break down material costs, machining time, setup fees, and any finishing processes. Be careful with quotes that seem too low compared to others. It might mean they are cutting corners on materials, quality checks, or even labor standards. Always ask questions if a price seems unclear or too good to be true.

Factors Influencing Cost:

- Material: Type and grade significantly impact price.

- Complexity: More intricate designs require more machine time and programming.

- Tolerances: Tighter tolerances need better machines and more inspection, increasing cost.

- Quantity: Larger volumes usually mean lower unit prices due to setup cost distribution.

- Finishing: Processes like anodizing, painting, or plating add to the cost.

Which Country is Best for CNC Machining?

People often ask where the "best" place for CNC machining is. There's no single answer. It really depends on your project's specific needs, like budget, quality requirements, and speed.

China is a top choice for CNC machining because it offers a strong mix of advanced technology, skilled labor, competitive pricing, and a complete supply chain. However, the "best" country depends on your specific priorities.

While China is a powerhouse, other countries have strengths too. For example, the US and Germany are known for extremely high precision and handling complex, regulated industries, but costs are higher. Countries like India and Vietnam are emerging with lower costs, but their capabilities and infrastructure might not be as developed as China's yet. I've worked with suppliers globally, and China consistently provides a great balance for many projects, especially when cost and speed are important. Their manufacturing ecosystem3 is vast – you can easily find suppliers for materials, machining, finishing, and assembly all in close proximity. This integration helps speed up production and reduce logistical challenges.

Quick Country Comparison:

| Feature | China | USA/Germany | India/Vietnam |

|---|---|---|---|

| Cost | Very Competitive | High | Competitive |

| Capability | Wide Range, Improving | Very High, Specialized | Developing |

| Speed | Fast | Moderate | Moderate to Fast |

| Supply Chain | Highly Developed | Developed | Developing |

| Best For | Balanced Needs, Scale | High Complexity, IP | Cost-Sensitive Simpler |

Ready to find your ideal CNC partner? Contact our sourcing experts for personalized supplier recommendations and quality assurance support for your China manufacturing projects.

Are Chinese CNC Machines Any Good?

There used to be a perception that Chinese-made machinery wasn't top quality. Does that still hold true for CNC machining capabilities today? Many buyers wonder about this.

Yes, reputable Chinese CNC shops often use high-quality imported machines (like Haas, Mazak, DMG Mori) alongside reliable domestic brands. Their machine quality and operator skill levels are often comparable to Western shops.

From my experience visiting many factories in China over the years, the landscape has changed dramatically. Top-tier suppliers invest heavily in good equipment. It's common to see workshops filled with globally recognized machine brands. They understand that quality output requires quality input. Furthermore, they invest in training their technicians and quality control staff. Many engineers and programmers are highly skilled. The key is finding the right supplier. Not all factories are equal. Lower-end shops might use older or less precise equipment. That's why verification and factory audits4 are important. You want to partner with a supplier committed to investing in technology and quality processes, ensuring they can meet your specifications consistently.

Assessing Supplier Capability:

- Machine Inventory: Ask for a list of their CNC machines, including brand, model, and age.

- Maintenance Records: Well-maintained machines perform better.

- Operator Experience: Skilled technicians are crucial for quality results.

- Quality Control Equipment: Do they have CMMs, projectors, and other necessary inspection tools?

My 5-Step Supplier Qualification Process

Here's the exact process I've developed over 15 years of sourcing from China:

Step 1: Technical Capability Assessment

- Request their machine list with model years

- Ask for case studies of similar parts they've produced

- Verify they have the right inspection equipment for your tolerances

Step 2: Quality System Verification

- Review their ISO certificate validity

- Ask for their standard inspection procedures

- Request sample inspection reports from previous jobs

Step 3: Communication Test

- Send a detailed RFQ with technical questions

- Note their response time and question quality

- Schedule a video call to assess English proficiency

Step 4: Sample Order

- Order 3-5 pieces of your most complex part

- Specify your inspection requirements upfront

- Pay for expedited shipping to test their urgency handling

Step 5: Small Production Run

- Place an order for 50-100 pieces

- Include clear acceptance criteria in the PO

- Conduct your own inspection upon receipt

"This process has saved me from countless bad partnerships. The suppliers who pass all five steps usually become long-term partners worth their weight in gold." - Senior Sourcing Manager

Conclusion

Finding reliable CNC machining suppliers in China is definitely possible with careful research and vetting. Focus on verifying their experience, capabilities, quality systems, and communication skills. Don't just chase the lowest price; look for the best overall value and a trustworthy partner.

Footnotes:

-

Learning about registered capital can provide insights into a company's financial stability and legal standing. ↩

-

Understanding ISO 9001 can help you appreciate its role in ensuring quality management in businesses. ↩

-

Understanding the manufacturing ecosystem can help you optimize production and logistics, ensuring better project outcomes. ↩

-

Factory audits help verify a supplier's capabilities and commitment to quality. ↩