Machining allowance often looks simple, but many precision parts fail because it is defined too early or too loosely. I have seen good designs turn into expensive problems because of this.

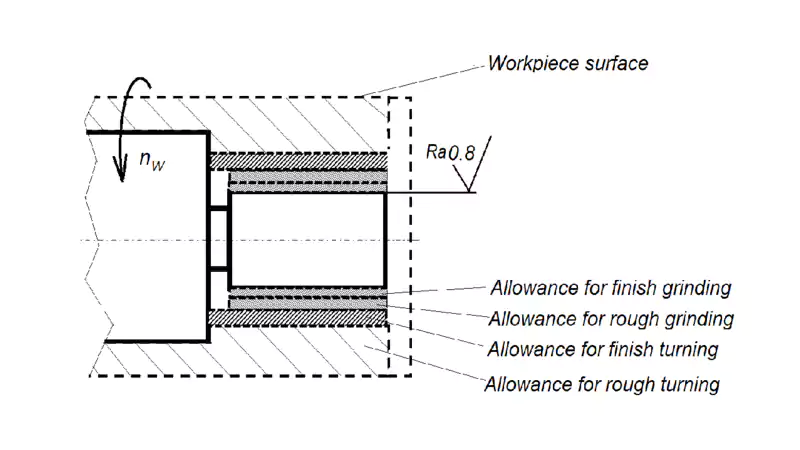

Machining allowance is the planned extra material left on a part so I can machine it to final size, accuracy, and surface quality in a controlled way. When defined well, it protects precision, cost, and delivery time.

I have worked with buyers and engineers from automotive, medical, and industrial equipment companies for more than twenty years. In that time, machining allowance has been one of the most misunderstood topics. To explain it clearly, I will walk through how I think about it in real CNC production.

The Role of Machining Allowance in Precision CNC Manufacturing?

Many engineers treat machining allowance as leftover stock, but this thinking often leads to distortion, scrap, or unstable quality. I see this problem again and again in global sourcing projects.

Machining allowance defines how much control I keep over accuracy, surface finish, and part stability during CNC machining. It is a process decision, not just a design value.

Machining allowance exists to manage uncertainty. Raw material moves. Tools wear. Heat builds up. If I remove all material at once, the part reacts. That reaction shows up as size drift1 or surface damage. By planning allowance, I split material removal into steps that the part can survive.

Why Machining Allowance Is Not “Extra Material”

Allowance is not waste. It is insurance. I use it to correct deformation from rough machining. I also use it to clean surfaces before finishing. Without allowance, finishing cuts lose reference and accuracy drops fast.

Machining Allowance and Functional Fits

Allowance supports function. For clearance fits, I need room to correct roundness and straightness. For interference fits, I need tight control in the last cut. In both cases, allowance protects function, not just size.

Machining Allowance in Engineering Drawings and Tolerancing?

Many sourcing problems start with drawings. I often receive drawings that specify tight tolerances but say nothing about machining allowance. This gap creates risk on both sides.

Machining allowance rarely appears as a number on the drawing, but it directly affects how tolerances are achieved during machining.

Allowance lives between design and manufacturing. Designers control final size. Machinists control how to get there. When this link is weak, cost rises and lead time grows.

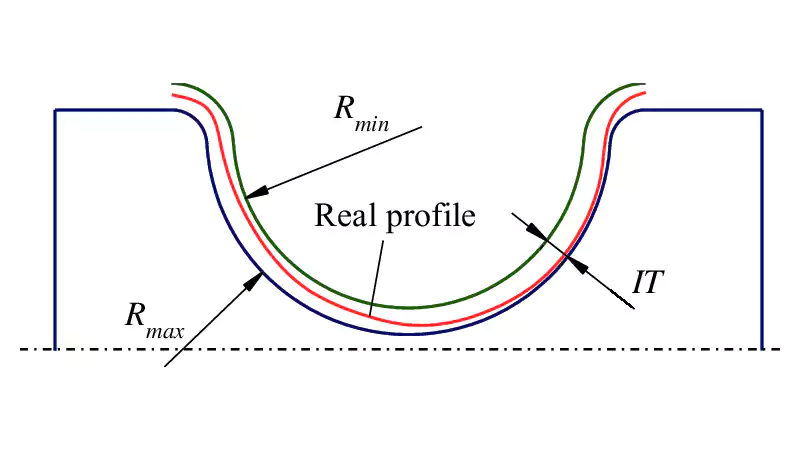

Machining Allowance vs. Dimensional Tolerance2

Tolerance defines the allowed size window. Allowance defines how I approach that window. Tight tolerance does not always mean small allowance. In fact, tighter tolerance often needs more allowance to stabilize the process.

Common Drawing Misunderstandings

Many engineers assume CNC machines cut perfectly. They do not. Machines follow programs, but materials react. Allowance gives me room to correct those reactions before final inspection.

How to Determine Machining Allowance in CNC Machining?

This is where experience matters most. There is no single formula that works for all parts. I decide allowance based on process, material, geometry, and risk.

Machining allowance is calculated by balancing material behavior, process capability, and final tolerance, not by using a fixed rule.

In my shop, allowance decisions often change between prototype and production. What works once may not work a thousand times.

Key Factors That Drive Machining Allowance

| Factor | Why It Matters |

|---|---|

| CNC process | Milling, turning, and grinding remove material very differently |

| Material | Hardness, internal stress, and heat response change behavior |

| Geometry | Thin walls and long features need more control |

| Setup count | More setups mean more error stacking |

Typical Allowance Ranges3 in Practice

| Process | Roughing Allowance | Finishing Allowance |

|---|---|---|

| CNC milling | 0.3–1.0 mm | 0.1–0.3 mm |

| CNC turning | 0.2–0.8 mm | 0.05–0.2 mm |

| CNC Grinding | 0.05–0.2 mm | 0.01–0.05 mm |

These values are starting points. I always adjust based on part response during trial runs.

Cost, Quality, and Lead-Time Implications?

Many buyers try to reduce allowance to save cost. In reality, this often increases total cost. I have seen projects fail because allowance was optimized too early.

Machining allowance directly affects cycle time, scrap rate, and delivery stability, especially in precision CNC machining.

Too little allowance forces slow feeds and extra checks. Too much allowance wastes machine time. The balance point is different for every part.

Case Study: Precision Aluminum Housing for Industrial Automation

| Parameter | Value |

|---|---|

| Material | Aluminum 6061-T6 |

| Final tolerance4 | ±0.01 mm |

| Initial allowance | 0.2 mm |

| Revised allowance | 0.5 mm |

| Scrap rate before | 12% |

| Scrap rate after | 1.5% |

| Cycle time change | +8% |

| Total cost change | −15% |

In this case, increasing allowance improved stability. Finishing cuts became predictable. Rework disappeared. Delivery became reliable.

Practical Guidelines and Common Mistakes?

After years of working with global buyers, I see the same mistakes repeat. Most of them are avoidable with early communication.

Clear agreement on machining allowance between engineer and supplier reduces cost, risk, and lead time.

Common Mistakes I See

- Assuming CNC machines remove material perfectly

- Forcing minimal allowance on thin or stressed parts

- Locking allowance before prototype validation

- Incorporate contour error into machining allowance

- Ignoring supplier feedback during quoting

Best Practices for Buyers and Engineers

When you send an RFQ, define function and tolerance clearly. Let the machining supplier decide allowance when possible. Ask how they plan to control deformation and finishing. This approach saves time and money.

Conclusion

Machining allowance is not excess material. It is a control tool that protects precision, cost, and delivery when CNC machining parts at a professional level.

-

Exploring the causes of size drift can help improve machining accuracy and reduce defects, enhancing overall production efficiency. ↩

-

Exploring Dimensional Tolerance can help you grasp its impact on precision and efficiency in production. ↩

-

Exploring typical allowance ranges helps in setting realistic expectations and improving machining accuracy in your projects. ↩

-

Learn about the significance of final tolerance in manufacturing to ensure quality and precision in production. ↩