Fasteners look small, so they are often sourced last. When supply fails, production stops fast and the real cost becomes very clear.

Sourcing custom motorcycle fasteners is a supply risk decision, not a simple price comparison, because manufacturing method, data quality, and supplier capability—many of which are defined during the custom motorcycle fastener design stage—directly affect cost, lead time, and long-term consistency.

I have worked on many projects where engineering was correct, but sourcing decisions caused delays. This article explains how procurement and engineering teams can reduce risk when sourcing custom fasteners for vehicle programs.

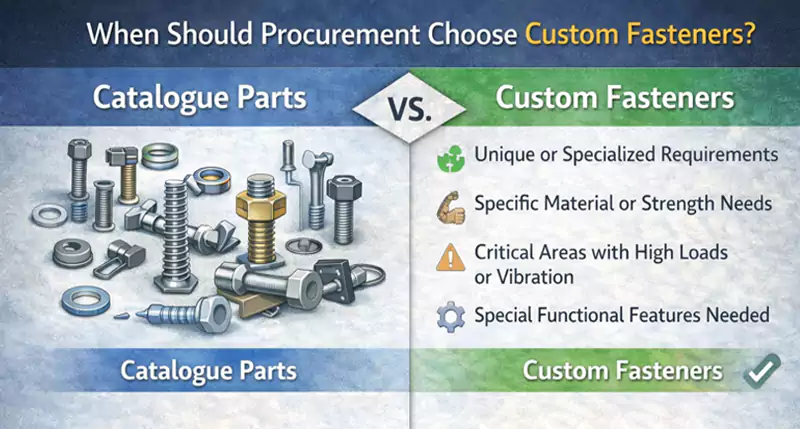

When Should Procurement Source Custom Fasteners Instead of Catalog Parts?

Catalog parts are easy to buy, but they are not always safe to rely on. Vehicle programs often expose their limits late in the project.

Custom fasteners should be sourced when catalog parts cannot meet design, durability, or supply consistency requirements.

For motorcycle OEMs and Tier-1 suppliers, custom motorcycle fasteners are often required when standard catalog parts cannot meet strength, weight, or geometry requirements.

In my experience, procurement teams often wait too long to switch from catalog to custom parts. This delay usually causes redesign or urgent sourcing later.

Common triggers for custom sourcing

Repeated loosening, early corrosion, or assembly difficulty are common signs. Another trigger is unstable supply. When a catalog part changes supplier or specification, production risk1 rises.

Why early sourcing decisions matter

Early custom sourcing allows stable drawings, controlled materials, and planned production methods. Late changes force shortcuts and increase cost.

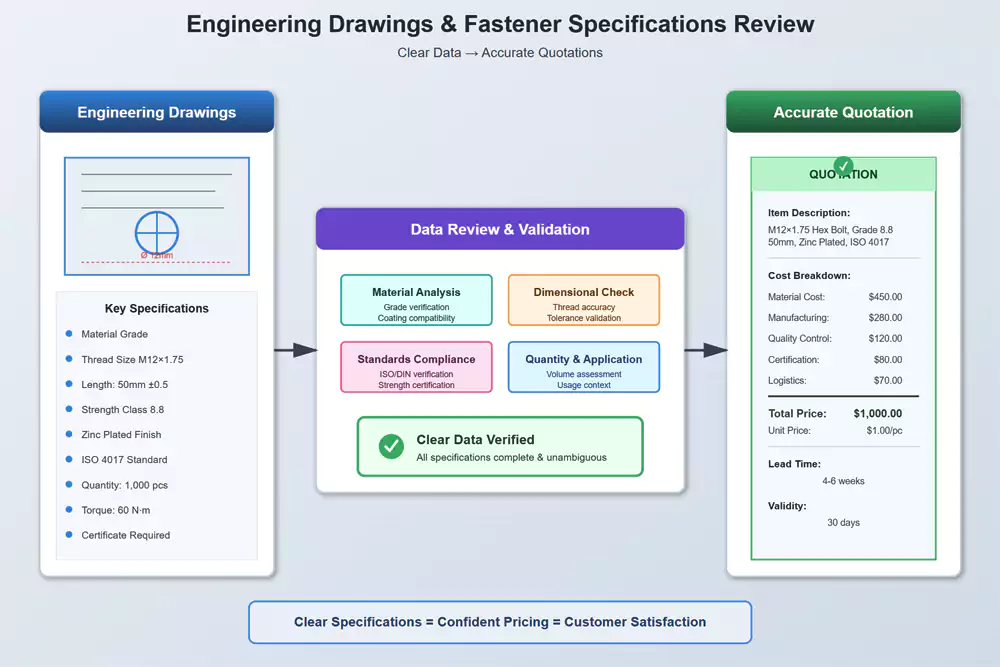

What Information Do Suppliers Need for Accurate Custom Fastener Quotes?

Fast quotes depend on clear input. Missing data always creates hidden cost later.

Suppliers need complete technical and commercial information to quote custom fasteners accurately and quickly.

I often see long email chains caused by unclear drawings. This wastes time on both sides.

Technical information that must be defined

CNC Machining Suppliers need clearly defined motorcycle fastener materials, heat treatment, surface finish, thread standard, and tolerances. Application details such as load and environment help avoid wrong assumptions.

Commercial information that affects pricing

Batch size, annual volume, and delivery schedule2 all affect cost. Small batches often favor CNC machining. Large volumes may justify forming tools.

Why incomplete data increases risk

When data is missing, suppliers guess. These guesses often lead to rework, price changes, or quality disputes later.

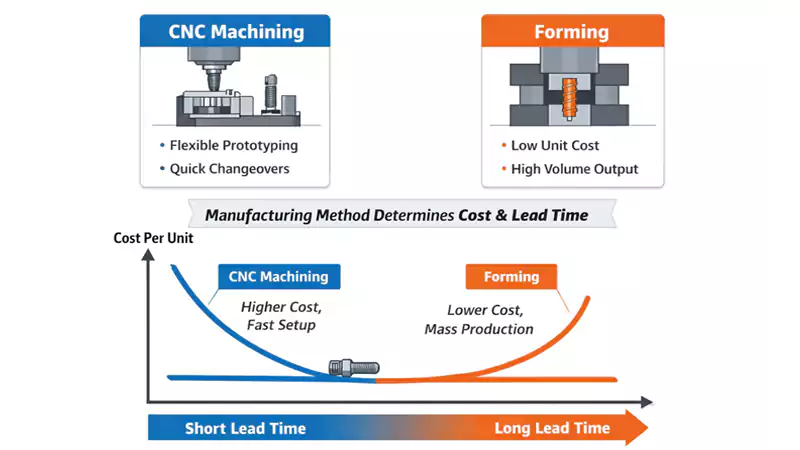

How Does CNC Machining Compare to Forming for Custom Fasteners?

The manufacturing method defines cost structure and flexibility. Choosing the wrong method creates long-term problems.

CNC machining offers flexibility and fast changes, while forming offers lower unit cost at stable high volume.

I often help customers choose a method based on project stage, not just unit price.

I often help customers choose a method based on project stage and fastener strength grades, not just unit price.

CNC machining advantages and limits

CNC machining works well for prototypes, validation builds, and medium volumes. Design changes are easy. Tooling cost is low. Unit cost is higher.

Forming advantages and limits

Cold forming3 delivers low unit cost at high volume. Tooling cost is high. Design changes are slow and expensive. Stable demand is required.

Choosing the right path

Many projects start with CNC machining and later move to forming. This staged approach reduces risk and supports validation.

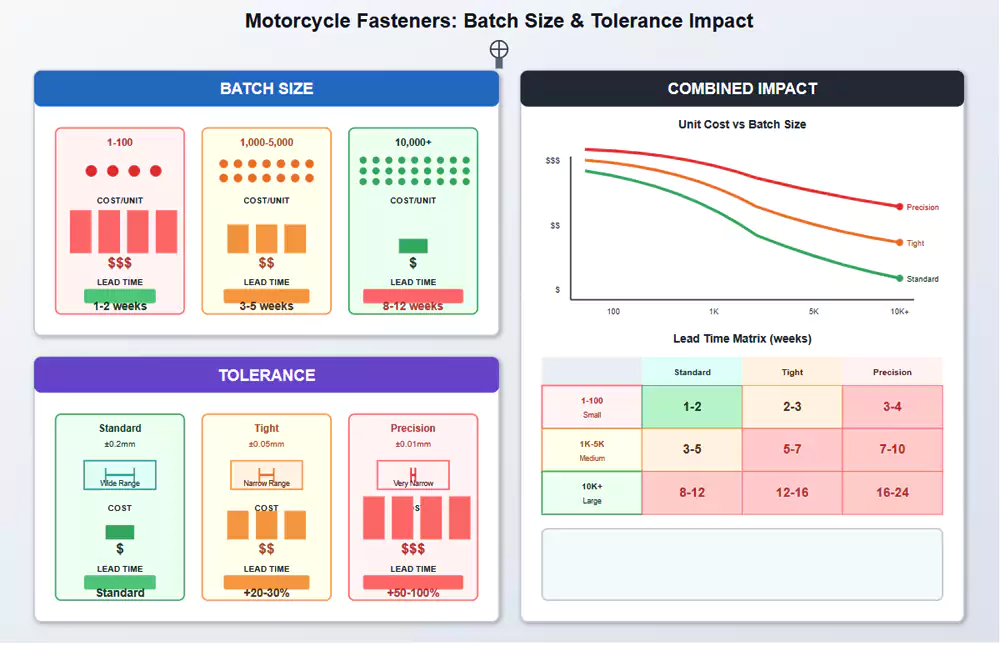

How Do Batch Size and Tolerances Drive Cost and Lead Time?

Fastener cost is not only about material. Process time and inspection effort matter.

Batch size and tolerance level directly control machining time, inspection cost, and delivery speed.

Procurement teams often focus on unit price without understanding why it changes.

Batch size effects

Small batches increase setup cost per part. Large batches reduce unit cost but increase inventory risk. The right balance depends on demand stability.

Tolerance effects

Tight tolerances increase machining passes and inspection time. Loose tolerances reduce cost but may affect assembly. Not all dimensions need tight control.

Practical cost drivers

Surface finish, secondary operations, and inspection reports all add cost. Clear priorities help suppliers optimize.

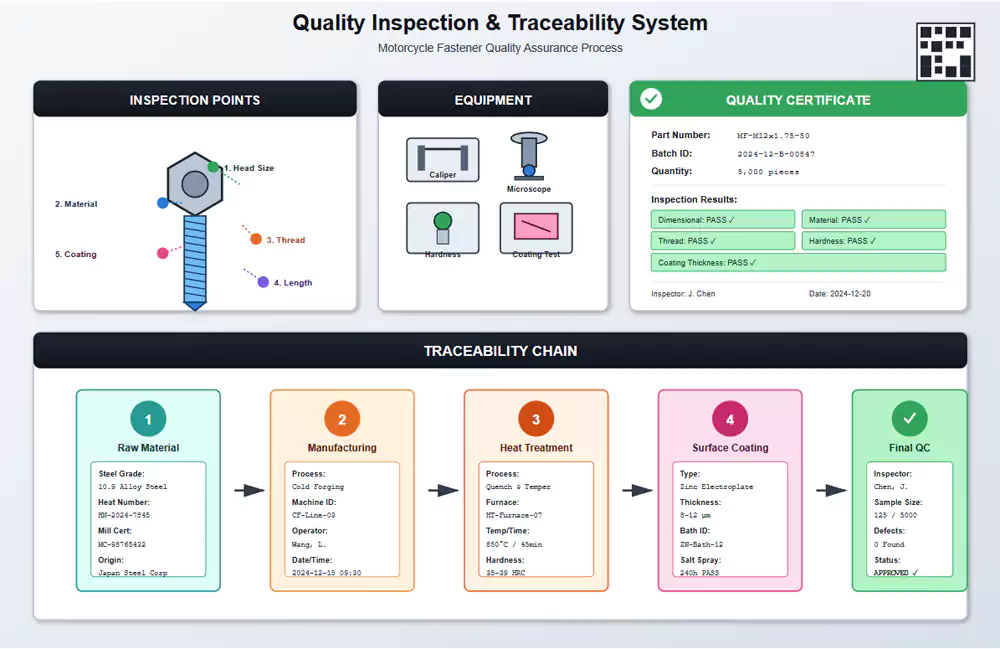

How Should Procurement Evaluate Quality Control and Traceability?

Quality issues cost more than price differences. Traceability protects both supplier and customer.

Strong quality control and traceability systems reduce production risk and support long-term supply stability.

I always advise procurement teams to review quality systems early.

Key quality elements to review

Material certificates4, process control, and inspection plans matter. Clear revision control prevents mix-ups.

Traceability in vehicle programs5

Lot tracking allows fast response if issues arise. This is especially important for safety-related fasteners.

Why quality systems matter more than price

Low price cannot compensate for recalls, line stops, or reputation damage.

How Can Procurement Identify a Reliable Long-Term Fastener Partner?

Long-term supply depends on trust and capability, not just contracts.

A reliable fastener partner supports engineering, communicates clearly, and scales with your production needs.

From my perspective as a machinist, good partnerships prevent problems before they appear.

Engineering support and communication

Suppliers should ask questions and flag risks early. Silence often means misunderstanding.

Capacity and process stability

Stable equipment and trained operators support consistent quality. Automation improves repeatability.

Case Study: Stabilizing the Supply of Custom Motorcycle Fasteners for Series Production

1. Project Context

A European motorcycle manufacturer was preparing a new model for series production. The program involved multiple fasteners used in high-vibration and outdoor-exposed assemblies, including suspension brackets and exhaust mounts.

The procurement team’s priority was to secure stable supply, predictable cost, and consistent quality across annual production volumes.

2. The Real Problem

Although the fasteners met basic drawing requirements, production issues appeared during pilot builds:

- Repeated delivery delays from multiple catalog suppliers

- Inconsistent coating quality between batches

- Assembly complaints caused by torque scatter and thread variation

These issues increased inspection workload and introduced line-stop risk.

3. Engineering Constraints (What Could NOT Be Changed)

Several factors were fixed and could not be renegotiated:

- Existing part interfaces and joint geometry

- Approved assembly torque values

- Target vehicle cost and SOP timeline

The solution had to improve supply stability without redesigning surrounding components.

4. Custom Solution (What Was Actually Changed)

Instead of continuing with off-the-shelf parts, the team consolidated to a single custom fastener design:

- One defined material grade and strength class

- Controlled thread length to match real joint stack-up

- Unified surface treatment for corrosion and friction stability

- Integrated flange head to reduce part count and assembly variation

This reduced specification ambiguity and eliminated supplier interpretation differences.

5. Manufacturing & Supply Strategy

The sourcing strategy focused on risk reduction, not lowest unit price:

- CNC machining selected for flexibility and revision control

- Fixed monthly batch sizes aligned with production planning

- Dedicated inspection plan and lot-level traceability

- Single manufacturing partner with direct engineering communication

This approach simplified procurement management and improved responsiveness.

6. Measurable Outcome (So What?)

After implementing the custom fastener program:

- Lead time reduced from 8–10 weeks to 4–5 weeks

- Zero delivery delays over two consecutive production quarters

- Assembly-related quality issues eliminated

- Inspection effort and supplier coordination workload reduced

Total landed cost became more predictable, despite a slightly higher unit price.

Key Takeaway

For procurement managers, custom motorcycle fasteners are not a cost upgrade—they are a supply stability tool.

Clear specifications, controlled manufacturing, and supplier consolidation reduce risk, workload, and long-term cost.

Conclusion

Successful custom fastener sourcing depends on clear data, correct manufacturing choices, and reliable long-term supplier partnerships.

-

Understanding production risk is crucial for procurement teams to mitigate issues and ensure smooth operations. ↩

-

Exploring this link will reveal how delivery schedules can significantly affect pricing and production efficiency. ↩

-

Learn about cold forming to see how it can be advantageous for high-volume production despite its challenges. ↩

-

Understanding best practices for managing material certificates can enhance your quality control processes and prevent costly errors. ↩

-

Exploring how traceability enhances safety and quality can provide insights into effective vehicle program management. ↩