Choosing the wrong fastener material can cause corrosion, loosening, or sudden failure. I have seen strong designs fail simply because material selection was rushed.

The right motorcycle fastener material depends on load, environment, and application location. Steel, stainless steel, titanium, and aluminum each solve different problems in real-world motorcycle use.

I often see engineers and buyers focus on price or appearance first. That usually leads to trouble later. Understanding how each material behaves helps avoid redesigns, delays, and field failures.

Why Material Selection Matters for Motorcycle Fasteners?

Fasteners may look small, but they carry critical loads and face harsh conditions every day.

Material selection determines strength, fatigue life, corrosion resistance, and long-term safety. In motorcycles, vibration, heat, and weather amplify every weakness.

When I review failed parts, the cause is often simple. The fastener material was not matched to its real working conditions. A frame bolt sees very different stress than a fairing screw. Treating them the same creates risk. Choosing correctly at the start saves time, cost, and reputation.

Common Materials Used in Motorcycle Fasteners?

Motorcycle fasteners rely on a small group of proven materials, each with clear strengths and limits.

Steel, stainless steel, titanium, and aluminum dominate motorcycle applications because they cover most structural, environmental, and cost needs.

I usually start material selection by asking one question. What does this fastener need to survive? Load, corrosion, or weight usually drives the answer.

Carbon & Alloy Steel (8.8 / 10.9 / 12.9)

Carbon and alloy steel fasteners offer high strength and predictable behavior.

Grades 8.8, 10.9, and 12.9 define fastener strength grades, including tensile strength and yield limits. Grade 8.8 works for brackets and accessories. Grade 10.9 is common for frames and engine mounts. Grade 12.9 is used when space is limited and loads are high.

| Grade | Tensile Strength | Typical Use |

|---|---|---|

| 8.8 | ~800 MPa | Brackets, mounts |

| 10.9 | ~1000 MPa | Frames, suspension |

| 12.9 | ~1200 MPa | Racing components |

Steel fasteners are cost-effective and easy to machine. The weakness is corrosion. Without proper plating, rust can quickly reduce strength. Zinc or zinc-nickel coatings are often necessary for outdoor use.

Stainless Steel (304 / 316 / A2 / A4)

Stainless steel fasteners resist corrosion better than carbon steel.

304 and A2 grades work well for general exposure. 316 and A4 perform better in salty or chemical environments1. Stainless steel is often chosen for visible parts because it stays clean.

| Grade | Corrosion Resistance | Strength Level |

|---|---|---|

| 304 / A2 | Good | Medium |

| 316 / A4 | Excellent | Medium |

The limitation is strength. Stainless fasteners are weaker than alloy steel. They also risk galling during assembly. I always recommend anti-seize when stainless threads are involved.

Titanium Alloy (Ti-6Al-4V)

Titanium offers high strength with much lower weight.

Ti-6Al-4V2 is widely used in racing and premium motorcycles. It provides excellent corrosion resistance3 and fatigue performance.

| Property | Typical Value |

|---|---|

| Density | ~4.43 g/cm³ |

| Tensile Strength | ~900 MPa |

Titanium costs more and is harder to machine. Tool wear is high, and heat control matters. Poor machining can reduce fatigue life. This material rewards experience.

Aluminum Alloy (6061 / 7075)

Aluminum fasteners reduce weight but have limited strength.

6061 is easy to machine and affordable. 7075 is much stronger but still weaker than steel or titanium.

| Alloy | Relative Strength | Typical Use |

|---|---|---|

| 6061 | Medium | Body panels |

| 7075 | High | Lightweight brackets |

Aluminum fasteners strip easily and fatigue faster. I only recommend them for non-structural parts.

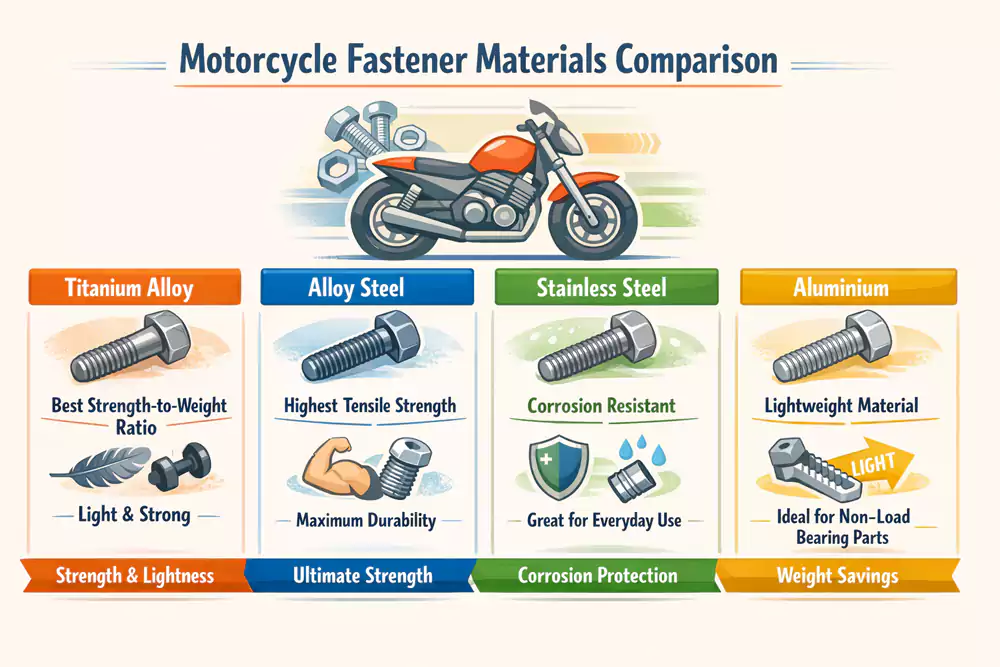

Mechanical & Performance Comparison of Fastener Materials?

Different materials behave very differently under load and vibration.

A direct comparison shows that Titanium offers the best strength-to-weight ratio, while Alloy Steel provides the highest absolute tensile strength. Stainless steel leads in corrosion resistance for daily riders, and aluminum is the champion of weight reduction for non-load-bearing parts.

| Material Type | Tensile Strength (MPa) | Density (g/cm³) | Corrosion Resistance | Typical Grade | Weight |

|---|---|---|---|---|---|

| Alloy Steel | 1040 - 1220 | 7.85 | Low (Needs Plating) | 10.9 / 12.9 | High |

| Stainless Steel | 500 - 800 | 8.00 | High | 304 / 316 | High |

| Titanium | 895 - 1000 | 4.43 | Excellent | Grade 5 (Ti-6Al-4V) | Low |

| Aluminum | 310 - 570 | 2.70 | Moderate | 6061 / 7075 | Very Low |

As a master craftsman with 20 years in the shop, I once worked on a custom racing project where we had to replace every steel bolt with titanium. The bike lost nearly 3 pounds of weight just from fasteners.

How to Choose the Right Fastener Material for Your Application?

Stop guessing and start analyzing. Match the material to the specific functional demand of the fastener's location on your bike. This decision is closely tied to how the fastener is designed, including head type, thread engagement, and load path, which we explain in detail in our guide on designing custom motorcycle fasteners.

Select material by application zone: High-strength steel for structural loads; Stainless for corrosion-prone areas; Titanium for critical weight-saving; Aluminum for secondary, low-stress lightweight needs; always balancing against your project budget.

High-strength structural components

For your engine mounts, swingarm pivots, and suspension links, strength is the only priority. I recommend Grade 10.9 or 12.9 alloy steel. If you have the budget, Grade 5 Titanium is a perfect upgrade here because it stays strong but never rusts. Never use aluminum or low-grade stainless here.

Weight-sensitive performance parts

If you are building a track bike, focus on "unsprung weight." This means parts attached to the wheels or brakes. Titanium axle bolts and brake caliper bolts make the suspension react faster. This makes the bike handle better in corners.

Budget and production volume considerations

For large production runs, cost is key. Plated alloy steel is the best balance for most manufacturers. If you are a custom shop building one-off bikes, the higher cost of stainless or titanium is worth it for the "wow" factor and long-term durability.

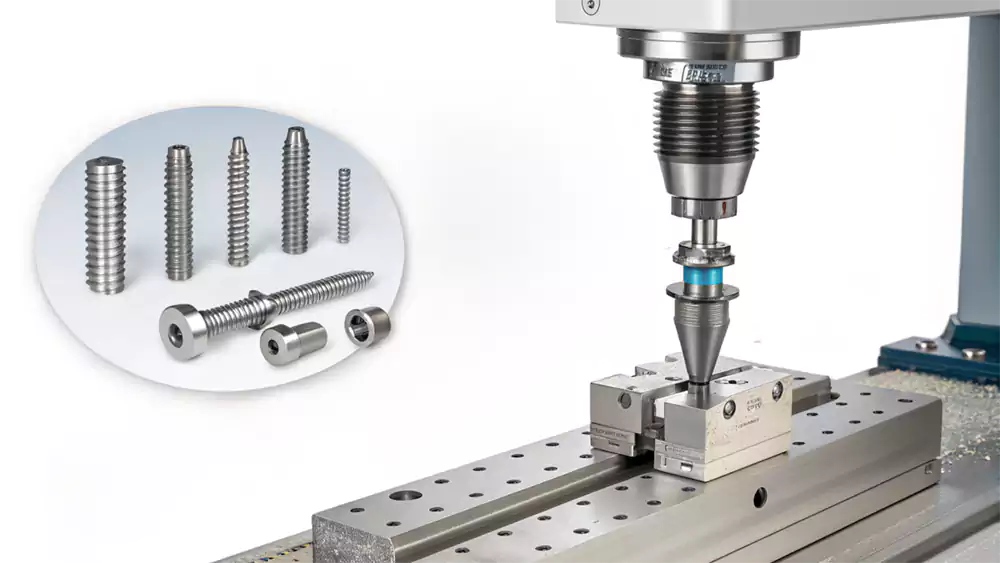

Manufacturing Considerations for Different Fastener Materials?

Why do some custom bolts cost five times more than others? The material you choose changes how we have to run our CNC machines and how we inspect the final product in our factory.

Manufacturing difficulty varies greatly: aluminum is fast to machine, stainless steel requires slow speeds to prevent hardening, and titanium is very tough on tools. Each metal also requires different surface treatments, such as anodizing for aluminum or zinc-plating for steel.

Machining difficulty by material

Aluminum is like butter; we can cut it very fast. This keeps the cost low. Titanium is the opposite. It generates a lot of heat and can even catch fire if the machinist is not careful. It wears out our expensive cutting tools quickly. This is why titanium fasteners have a much higher price tag.

Tolerance control & inspection

When we machine high-tensile steel, it is very stable. We can hold very tight tolerances, down to ±0.005mm. Stainless steel can "creep" or expand with heat during the cutting process. We have to use high-pressure coolant to keep the dimensions exact. Every batch of custom fasteners must go through a thread gauge check to ensure they won't strip during assembly.

Surface Finishing Options

Steel requires plating (e.g., chrome, zinc) for protection. Aluminum excels with anodizing, which builds a hard, colored layer. Titanium forms a protective oxide naturally and can be heat-blued to achieve custom purple-blue finishes. For aesthetics, stainless steel benefits from polishing, while titanium is well-suited for precise laser marking.

Case Study: Custom Titanium Frame Fasteners

| Parameter | Value |

|---|---|

| Material | Ti-6Al-4V |

| Tolerance | ±0.01 mm |

| Quantity | 220 pcs |

| Application | Performance motorcycle frame |

| Surface Finish | Bead blast |

| Marking | Laser marking |

| Lead Time | 14 days |

In this project, thread milling was used instead of rolling to avoid galling. Assembly torque became more consistent, and rework dropped.

Working with a Custom Motorcycle Fastener Manufacturer?

You have a unique design, a broken OEM part that's discontinued, or a need for a specific material in a odd size. This is where partnering with a specialist CNC machine shop transforms the process.

A custom manufacturer provides engineering support to optimize your design for manufacture (DFM), handles small to medium batches cost-effectively, and offers expert material selection guidance to turn your blueprint into a reliable, high-performance component.

For buyers and engineers, understanding how to evaluate suppliers, pricing, and lead times is equally important, which we cover in our guide on sourcing custom motorcycle fasteners.

At Allied Metal, we don't just take your order. We look at your design. If we see you are using an expensive 5-axis design when a 4-axis design would work, we tell you. This is our DFM (Design for Manufacturability) process. We help you pick between 7075 aluminum or Grade 5 titanium based on your real-world needs. We focus on helping you get a quote in 24 hours so your project never stops moving. Whether you require Custom machining of 50 or 5,000 motorcycle fasteners, we ensure consistent quality every single time.

Conclusion: Balancing Performance, Cost, and Reliability

In the selection of motorcycle fasteners, there is no one-size-fits-all “best” material. The true solution lies in striking the right balance for your specific application—considering load, environment, weight targets, and budget. It's the practical experience of a trusted manufacturing partner that transforms these material specifications into safe, high-performance, and reliable components for your build.

Ready to find the optimal balance for your project? Contact our team today for a expert review of your designs and a quote on precision-machined fasteners that meet your exact requirements.

-

Read more about various chemical environments relevant to engineering. ↩

-

Explore this link to learn about the physical and mechanical properties of titanium alloy Ti-6Al-4V, along with its applications, specifications, and more. ↩

-

Discover how titanium alloys, especially Ti-6Al-4V, excel in corrosion resistance, making them ideal for harsh environments. ↩