Fastener failures on motorcycles often appear sudden, but the causes are almost always predictable. Vibration, cyclic loads, and poor strength selection quietly build risk until something breaks.

Motorcycle fastener strength grades matter because they influence fatigue life, safety margins, and serviceability—not just maximum load capacity. Choosing the wrong grade can cause failure even when the bolt appears “strong enough.”

Motorcycles operate in an environment that punishes fasteners. High-frequency vibration, changing loads, and limited joint space combine to expose weaknesses in both design and material choice. I have seen many cases where a bolt met the strength specification on paper but failed early in real use. Understanding why requires going beyond strength numbers and looking at how fasteners actually work on a motorcycle.

Why Fastener Strength Grades Matter in Motorcycle Engineering?

Motorcycle fasteners live in a harsher world than many industrial bolts. Engines vibrate constantly. Road surfaces introduce shock loads. Riders demand lighter structures without sacrificing safety. All of this makes strength grades more than just catalog data.

Fastener strength grades matter because motorcycle joints are dominated by vibration and cyclic stress, not static load. Reliability depends on fatigue resistance and installation margin as much as raw strength.

When I evaluate motorcycle fasteners, I always start with operating conditions. Unlike static machinery, motorcycles see thousands of load cycles per hour. Even a small change in preload or alignment can shift stress into dangerous zones. This is why a higher strength grade does not automatically mean better performance.

OEM manufacturers usually design for long service life and predictable maintenance. They favor fasteners that tolerate variation in torque, surface condition, and assembly skill. Aftermarket and custom builders often focus on strength numbers or weight savings. This gap in philosophy explains why failures appear more often in modified motorcycles. Strength grades matter because they must match how the bike is used, assembled, and maintained.

Understanding Motorcycle Fastener Strength Grades and Materials?

Bolt grades and materials are often discussed separately, but in practice they must be considered together. Strength comes from both chemistry and processing.

Motorcycle bolt grades define tensile limits, while materials and heat treatment determine ductility, fatigue behavior, and failure mode. All three factors work together.

Metric strength grades such as 8.8, 10.9, and 12.9 describe minimum tensile and yield strength. An 8.8 bolt offers moderate strength with good ductility1. A 10.9 bolt increases strength but narrows the safety margin. A 12.9 bolt delivers very high tensile strength2 but becomes less forgiving during installation and service.

Material choice changes how these grades behave, which is why understanding motorcycle fastener materials is critical to reliable joint design. Alloy steel provides the highest absolute strength. Stainless steel offers corrosion resistance but lower yield strength and a tendency to gall. Titanium alloys provide excellent strength-to-weight ratios but require careful torque control and surface treatment. Heat treatment further shifts this balance by trading ductility for hardness. In my experience, many failures come from selecting the correct grade but pairing it with the wrong material for the joint.

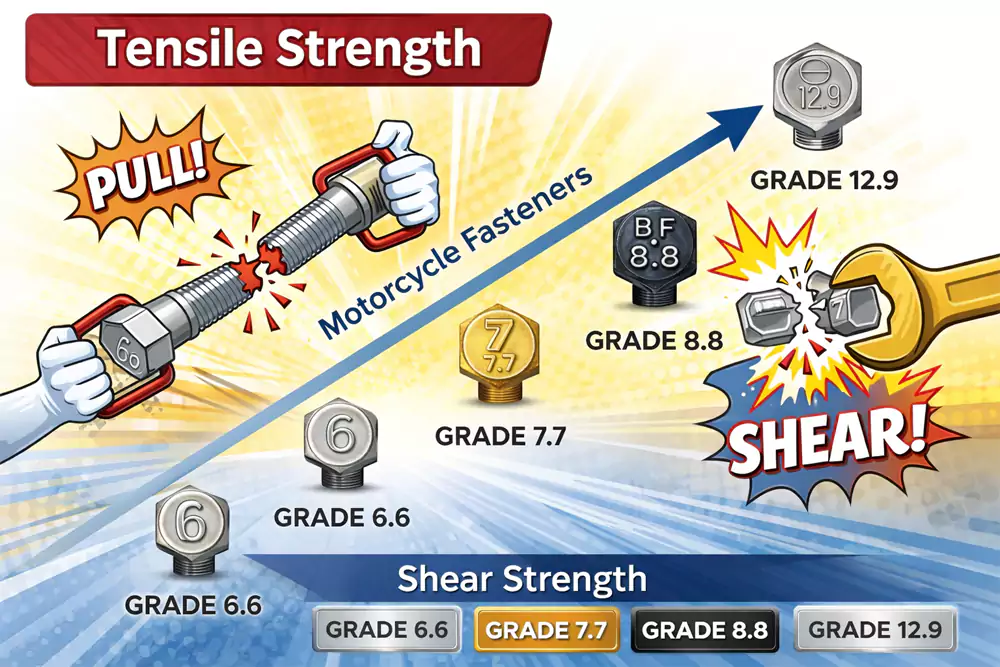

Tensile Strength vs Shear Strength in Motorcycle Fasteners?

This is where most misunderstandings begin. Many designers focus on tensile strength because it is easy to compare and widely published.

Tensile strength measures how much axial load a bolt can withstand, but most motorcycle fasteners fail under shear, bending, or fatigue driven by preload loss.

Tensile strength matters when a bolt is directly pulled apart. In motorcycle applications, this is rare. Most joints rely on clamp force to prevent movement. The friction created by preload carries the load. When preload drops, shear forces transfer into the bolt shank and threads.

Shear loading appears in brake calipers, suspension links, and engine mounts. If the joint slips, the bolt experiences alternating shear stress. This is far more damaging than static tension.Clamp force, not ultimate tensile strength, is what keeps the joint stable in motorcycle fastener design. I often see designs where a higher grade bolt was selected, but surface finish, lubrication, or torque accuracy were ignored. The result is preload loss3 and early fatigue failure.

Common Motorcycle Fastener Failure Modes and Root Causes?

Fastener failures usually follow clear patterns. Understanding these patterns helps prevent repeat mistakes.

Most motorcycle bolt failures trace back to fatigue, over-tightening, or stress concentration, not insufficient tensile strength.

Fatigue failure develops slowly. Vibration and cyclic loading create micro-cracks at thread roots or under the head. These cracks grow until the remaining cross-section cannot carry the load. Over-tightening is another common cause. Excess torque pushes the bolt past yield, reducing fatigue life even if the bolt does not break immediately.

Stress concentration worsens both problems. Sharp thread roots, poor surface finish, or mismatched washers increase local stress. Installation conditions also matter. Dry threads, lubricated threads, or coated threads all change the relationship between torque and preload. Ignoring these details turns even high-grade bolts into failure risks.

Case Study: Rear Suspension Link Bolt Failure

| Parameter | Value |

|---|---|

| Bolt Size | M10 x 1.25 |

| Material | Alloy Steel |

| Strength Grade | 12.9 |

| Applied Torque | 55 Nm |

| Joint Material | Aluminum Link |

| Failure Mode | Fatigue fracture at first thread |

The bolt met strength requirements, but the aluminum threads relaxed over time. Preload dropped, shear loads increased, and fatigue cracks formed. A 10.9 bolt with controlled torque and surface treatment would have performed better.

Why Higher Strength Fasteners Are Not Always Better?

This is one of the hardest lessons for engineers and builders to accept.

Higher strength fasteners reduce ductility and installation tolerance, which can shorten service life in real motorcycle joints.

As strength increases, elongation decreases. This reduces the bolt’s ability to absorb shock and vibration. High-strength bolts also operate closer to their yield point during installation. Small torque errors can push them into plastic deformation.

Aluminum threads make this worse. The joint relaxes, preload drops, and the stiff bolt takes more cyclic stress. In many cases, medium-strength fasteners outperform high-strength ones because they maintain preload better and tolerate variation—an important consideration when sourcing custom motorcycle fasteners. Over-specifying strength often shifts failure from gradual loosening to sudden fracture. From a safety standpoint, that is a step backward.

Engineering-Based Fastener Selection and Custom CNC Solutions?

The right fastener choice comes from system-level thinking, not isolated strength values.

Custom CNC-machined motorcycle fasteners allow strength, geometry, and surface condition to be optimized together for fatigue resistance and serviceability.

When I work with custom motorcycle projects, I look at each subsystem separately. Suspension and braking require stable preload and fatigue resistance. Engine covers and accessories prioritize corrosion resistance and ease of service. Coatings, thread form, under-head radius, and shank length all influence performance.

Custom CNC machining makes these adjustments possible. By controlling fillet radii and surface finish, stress concentration drops. By tuning thread engagement and material pairing, preload stability improves. This approach aligns with how professional motorcycle manufacturers design fasteners, and it is why custom fasteners often outperform off-the-shelf parts in demanding applications.

Conclusion

Motorcycle fastener reliability comes from balance. Strength matters, but ductility, fatigue resistance, and serviceability matter just as much. Designing for real loads always beats chasing higher numbers.

-

Exploring ductility helps in understanding how materials behave under stress, which is vital for safety and performance. ↩

-

Understanding tensile strength is crucial for selecting the right materials for construction and engineering projects. ↩

-

Exploring preload loss helps in preventing early fatigue failure, enhancing the longevity and reliability of mechanical joints. ↩