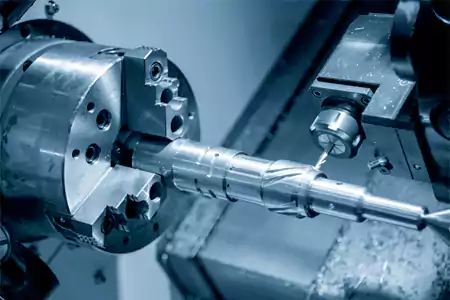

Precision Molybdenum CNC Machining Services

With 20+ years of expertise in refractory metal machining, Allied Metal delivers high-quality molybdenum components for demanding applications across aerospace, medical, automotive, and electronics industries.

CNC Machines

Production Facilities

Precision Tolerance

Days Rapid Turnaround

Properties of Molybdenum

Molybdenum offers exceptional characteristics that make it ideal for demanding machining applications.

High-Temperature Strength

With a melting point of 2,623°C (4,753°F), molybdenum maintains structural integrity in extreme heat, making it perfect for aerospace and power generation applications.

Superior Thermal Conductivity

Excellent heat dissipation prevents tool and workpiece overheating during machining, ensuring precision and prolonging tool life.

Chemical Inertness

High resistance to corrosion and chemical reactivity makes molybdenum ideal for aggressive environments and harsh operating conditions.

Enhanced Machinability

Despite its robustness, molybdenum can be precisely machined using conventional methods, allowing for intricate designs and tight tolerances.

Common Molybdenum Alloys We Machine

Choosing the right grade for your specific application.

| Alloy Grade | Composition | Key Characteristics | Typical Applications |

|---|---|---|---|

| Pure Molybdenum (99.95%) | Mo > 99.95% | High purity, good conductivity, easy to machine relative to alloys. | Heating elements, Electronic components. |

| TZM Alloy | Mo + 0.5% Ti + 0.08% Zr | Higher strength at high temps, higher recrystallization temp. | Structural furnace parts, Nozzles, Casting molds. |

| Mo-La (Lanthanum) | Mo + 0.3-0.7% La2O3 | Superior creep resistance, ductility after recrystallization. | High-temp vacuum furnace shielding, filaments. |

| Mo-Cu (Copper) | Mo + Cu (15-50%) | Tailored thermal expansion, high conductivity. | Heat sinks, Electronic packaging. |

*Note: These specifications are for reference. Contact our engineers for detailed material selection guidance.

Our Molybdenum Capabilities

Molybdenum is abrasive and brittle. We use specialized tooling and EDM to ensure precision.

CNC Milling (3, 4 & 5 Axis)

Complex geometries for heat sinks and structural brackets. We use carbide tooling to prevent chipping.

CNC Turning

Precision turning for rods, pins, and electrodes with tolerances down to +/- 0.005mm.

Wire EDM & Sinker EDM

Crucial for Molybdenum. Non-contact machining prevents micro-cracking and achieves intricate details.

Surface Finishes for Molybdenum

Polished

Mirror-like finish (Ra 0.1-0.4) for optical/semiconductor parts.

Ground

Precision grind for tight flatness (Ra 0.4-0.8).

Sandblasted

Matte uniform texture for cleaning and coating prep.

Electroplated

Gold, Nickel, or Rhodium plating to improve solderability.

Ion Source Filament Flexure Clamps

A semiconductor client needed a filament holder for an ion implanter operating at 2,000°C. Standard rigid clamps were causing filament breakage due to thermal expansion mismatch. The part required a specific “spring-like” capability in brittle TZM Molybdenum.

Allied Metal engineered a compliant flexure mechanism directly into the solid Molybdenum block. We utilized high-precision Wire EDM to cut a 0.02mm curved gap, allowing the part to expand elastically under heat without losing clamping force.

Wire EDM Cut Tolerance

Operating Temperature Stability

Vacuum Leak Test Pass Rate

Why Choose Allied Metal for Molybdenum Parts?

We solve “Supply Chain Anxiety” with specialized molybdenum machining expertise for reliable, high-quality components.

Our engineers provide free Design for Manufacturing analysis for molybdenum parts, optimizing designs for manufacturability and cost-effectiveness.

Specialized tooling and cooling techniques deliver precision molybdenum prototypes in 7-10 days without compromising quality.

200+ machines across two facilities ensure uninterrupted production of your molybdenum parts, even during peak demand.

From 1 prototype to 10,000 parts - no massive minimum order quantities. Perfect for R&D, pilot runs, or scaling production.

CMMs, Optical Projectors, and Materials Testers ensure every molybdenum part meets specifications with full dimensional reports.

20+ years experience optimizing cutting parameters and tool selection for molybdenum to reduce costs without sacrificing quality.

Specialized Molybdenum Processing Capabilities

Allied Metal’s extensive experience with molybdenum enables us to handle challenging aspects that other manufacturers struggle with:

- Preventing micro-cracking during machining of brittle molybdenum

- Maintaining dimensional stability despite molybdenum's thermal expansion characteristics

- Achieving fine surface finishes on this challenging material

- Precision machining of complex geometries for high-temperature applications

- Material selection guidance (pure Mo, TZM, MoRe, etc.) for optimal performance

- End-to-end solutions from machining to finishing and inspection

Molybdenum Parts We Machine

We specialize in precision machining of complex molybdenum components for demanding applications across diverse industries.

High-strength, heat-resistant components for extreme aerospace environments.

• Turbine blades and nozzles • Structural and engine parts • Heat shields • Rocket nozzle inserts • Aircraft fasteners

Components requiring excellent thermal and electrical conductivity.

• Heat sinks and spreaders • Semiconductor fixtures • Circuit board substrates • Power electronics • LED heat management

Biocompatible, precision components for medical applications.

• Surgical instruments • Orthopedic implants • Radiation shielding • Diagnostic equipment • Medical imaging

Durable parts requiring wear resistance and thermal stability.

• Molds, dies, and tooling • Furnace parts • Wear-resistant components • Industrial heating • Process equipment

Components for power generation systems.

• Gas/steam turbine parts • Nuclear reactor components • Heat exchangers • Power plant fixtures • Renewable energy

High-performance parts for automotive applications.

• Engine/exhaust components • Transmission parts • Turbocharger components • Brake system parts • High-temperature sensors

Precision components for scientific research.

• Laboratory equipment • Analytical instruments • Vacuum system parts • X-ray components • Research reactor

High-reliability components for defense systems.

• Protective components • Weapon system parts • Military vehicle parts • Communication equipment • Surveillance systems

Ready to Start Your Molybdenum Project?

Our team of molybdenum specialists is ready to help you with your precision components. Get a free DFM analysis and quote for your project today.