Motorcycle fasteners may look simple, but many teams still face failures, delays, or cost overruns because the wrong process was chosen too early.

Motorcycle fasteners are precision parts, and the right manufacturing process affects strength, cost, and long-term reliability more than most teams expect.

I have spent over twenty years working in CNC machining shops, cutting, turning, and inspecting fasteners used in motorcycles, racing machines, and high-performance bicycles. I have learned that good parts start with good process decisions, not just good drawings. For readers who want a broader overview of custom motorcycle fasteners manufacturing, this article focuses specifically on how manufacturing processes influence real-world performance, cost, and scalability.

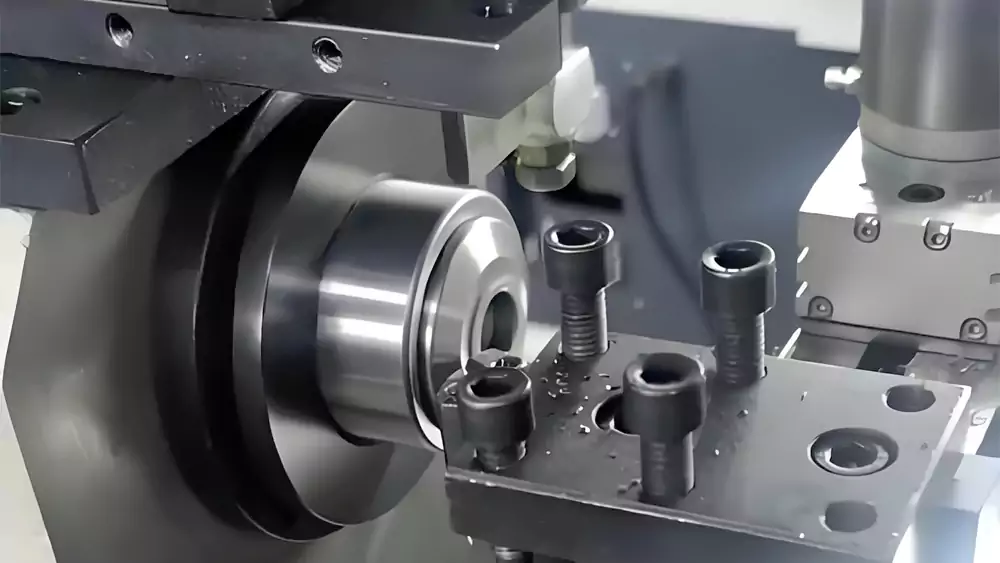

CNC Turning for Motorcycle Fasteners?

CNC turning is often chosen by default, yet it is not always the best or the most cost-effective option.

CNC turning is ideal for custom motorcycle fasteners that require tight tolerances, frequent design changes, or low to medium production volumes.

I use CNC turning when flexibility matters more than raw unit cost. On the shop floor, CNC lathes1 allow me to adjust dimensions, chamfers, undercuts, and head profiles without changing tooling. This is critical during early design stages or when engineers are still refining stress points and assembly fits.

When CNC Turning Makes Sense

CNC turning works well for axles, shoulder bolts, hollow bolts, and special studs. These parts often have multiple diameters, relief grooves, or internal bores. CNC turning handles this complexity in one setup. Tolerances of ±0.01 mm are realistic with stable tooling and proper inspection.

CNC turning also supports a wide range of materials. I routinely machine alloy steel, stainless steel, titanium, and aluminum. Material choice alone can influence machining strategy, cycle time, and final performance, which is why understanding motorcycle fastener materials is critical before locking in a process.

CNC Turning Limitations

The main drawback is speed. CNC turning removes material, so waste and cycle time increase cost. For high-volume standard bolts, CNC turning becomes expensive quickly. In my experience, once quantities exceed several tens of thousands per year, other processes should be evaluated.

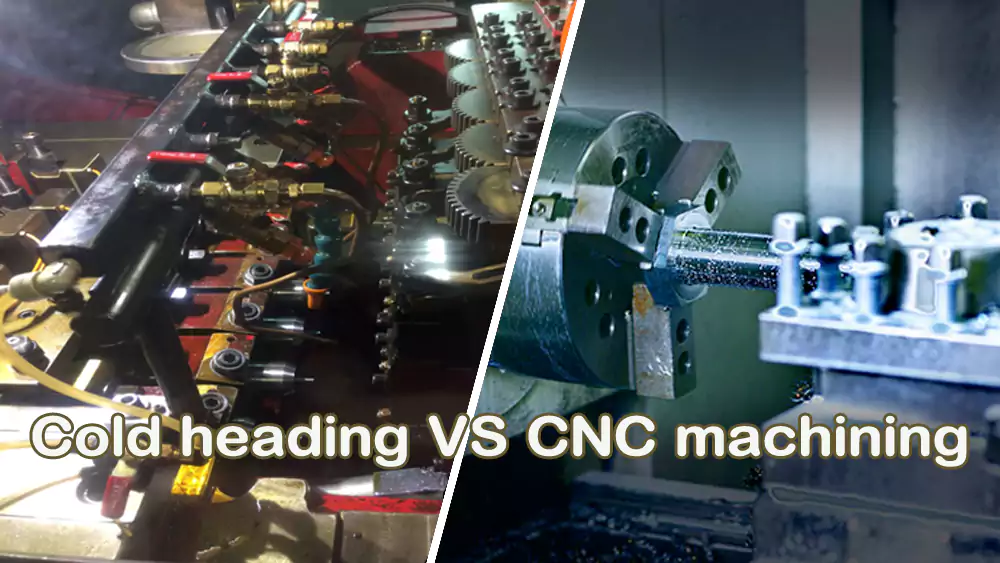

Cold Heading vs. CNC Machining?

Many teams struggle with this decision, especially when moving from prototype to production.

Cold heading is best for high-volume standard fasteners, while CNC machining excels in custom designs and lower production volumes.

I have seen projects fail because cold heading was selected too early. I have also seen CNC machining push costs too high when volumes increased. The key difference lies in how the metal flows during forming.

Cold Heading2 in Practice

Cold heading forms fasteners by deforming metal wire at room temperature. This creates continuous grain flow along the fastener axis. For standard bolts, this improves strength and fatigue life. Once tooling is ready, production speed is extremely high.

However, tooling cost is high and changes are slow. Design flexibility is limited. Features such as deep undercuts, side holes, or complex head shapes are difficult to achieve.

CNC Machining in Practice

CNC machining cuts material away, which breaks grain flow but allows far greater geometric freedom. I rely on CNC machining when designs are still evolving or when production volumes do not justify forming dies. It also allows tighter control over tolerances and surface details.

| Factor | Cold Heading | CNC Machining |

|---|---|---|

| Ideal volume | Very high | Low to medium |

| Design flexibility | Low | Very high |

| Tooling cost | High | Low |

| Unit cost | Very low at scale | Higher |

| Lead time | Long setup | Fast |

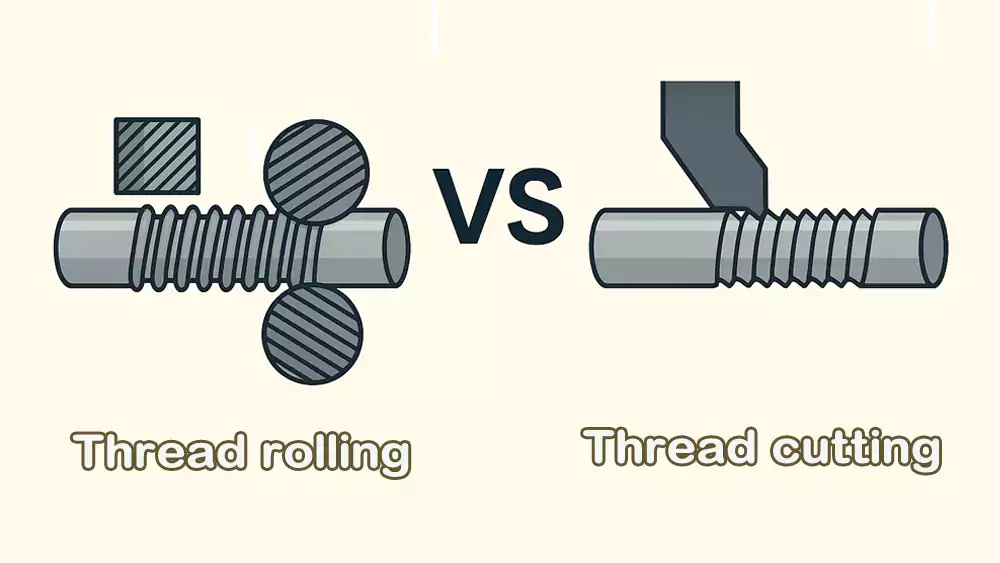

Thread Cutting vs. Thread Rolling?

Threading choice directly affects fatigue life, yet many teams overlook it.

Thread rolling produces stronger threads with better fatigue resistance, while thread cutting offers flexibility for low volumes and hard materials.

Whenever fatigue failure is a concern, thread rolling deserves serious attention.

Thread Rolling Effects

Thread rolling displaces material rather than removing it. This compresses the grain structure and improves surface finish at the thread root. In motorcycle applications, this often improves fatigue life3 by 20–40%. Rolled threads also show better consistency in production and align well with higher motorcycle fastener strength requirements.

Thread Cutting Effects

Thread cutting removes material and creates sharper root profiles. Fatigue performance is lower, but flexibility is high. I typically use thread cutting for prototypes, low volumes, or very hard materials where rolling tools would wear too quickly.

| Aspect | Thread Cutting | Thread Rolling |

|---|---|---|

| Fatigue strength | Lower | Higher |

| Surface finish | Fair | Excellent |

| Tooling cost | Low | Medium |

| Best for | Prototypes | Production |

Choosing the Right Process for Low-Volume and Custom Fasteners?

Low-volume projects require a different approach from mass production.

For custom or low-volume fasteners, process flexibility and early communication matter more than theoretical unit cost.

Most projects I support involve batches from 50 to 5,000 pieces. These fasteners are often revised after testing. CNC machining allows fast iteration. Dimensions, head geometry, or thread length can be adjusted without new tooling. Many of these decisions originate during the early stages of designing custom motorcycle fasteners.

Prototype to Small-Batch Flow

I usually recommend CNC turning combined with thread cutting for first samples. Once the design is frozen and fatigue performance is validated, thread rolling can be introduced. This staged approach reduces risk and avoids locking into an unsuitable process too early.

Case Study: Custom Racing Caliper Bolt

| Parameter | Value |

|---|---|

| Material | 42CrMo4 |

| Diameter | M10 |

| Length | 45 mm |

| Tolerance | ±0.01 mm |

| Quantity | 800 pcs |

| Process | CNC turning + thread rolling |

| Fatigue target | >1 million cycles |

The customer initially used thread cutting and experienced early failures during track testing. Switching to rolled threads increased fatigue life by over 30% without changing the bolt geometry.

Process Selection Matrix for Custom Motorcycle Fasteners?

Clear process selection reduces cost, risk, and rework.

A simple decision matrix helps teams align design stage, volume, and performance targets before production begins.

I often use this matrix when discussing sourcing custom motorcycle fasteners with engineering and procurement teams.

| Design Stage | Volume | Priority | Recommended Process |

|---|---|---|---|

| Concept | <100 | Speed | CNC turning + cutting |

| Prototype | 100–1,000 | Flexibility | CNC turning |

| Pilot | 1,000–5,000 | Strength | CNC + rolling |

| Production | >20,000 | Cost | Cold heading |

This framework keeps decisions practical and helps teams move from prototype to production with fewer surprises.

Conclusion

Reliable motorcycle fasteners result from clear process decisions made early, not from chasing the lowest unit price at the end.

-

Discover the benefits of CNC lathes and how they streamline production while allowing for quick adjustments. ↩

-

Understanding Cold Heading can help you grasp its advantages in fastener production and its impact on material properties. ↩

-

Understanding fatigue life is crucial for improving material performance and longevity in engineering applications. ↩