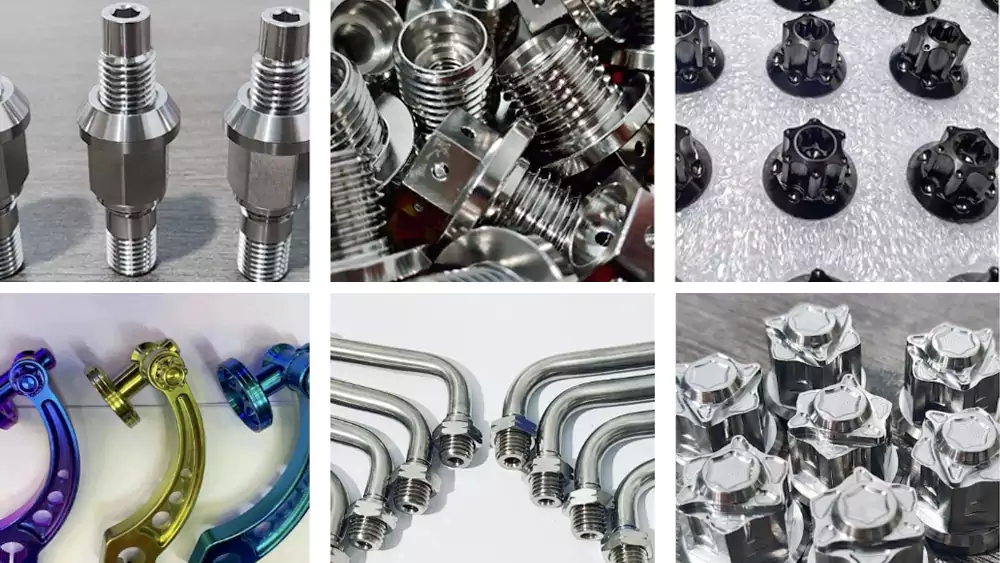

Custom motorcycle fasteners often look simple, but they fail late, cost time, or block programs when the manufacturing process is chosen incorrectly.

CNC machining is the most reliable option for custom motorcycle fasteners when volumes are low, designs are non-standard, and development speed matters, because it delivers precision, flexibility, and predictable quality without tooling risk.

In my daily work, I often see motorcycle fasteners become bottlenecks rather than simple purchased parts. Engineers finalize assemblies, but sourcing stalls because standard suppliers cannot support small quantities or fast revisions. This is exactly where CNC machining shows its real value. For readers who want a broader overview of the topic, I usually recommend starting with this resource hub on custom motorcycle fasteners manufacturing, which explains the full landscape in more detail.

What Makes Custom Motorcycle Fastener Projects So Difficult?

Custom motorcycle fastener projects are challenging because they sit between development urgency and production-level quality expectations.

The core difficulty lies in small batch sizes, non-standard geometries, tight tolerances, and program schedules that leave no room for slow tooling decisions.

From my experience, many procurement teams underestimate how complex fastener sourcing becomes once parts move beyond catalog standards. These challenges are also discussed in more detail in this guide on sourcing custom motorcycle fasteners, which reflects many real-world purchasing scenarios.

Low Volume Rejection by Traditional Suppliers

Cold heading and forging suppliers are optimized for long runs. When quantities drop below a few thousand pieces, quoting becomes difficult or impossible. Even if suppliers accept the job, the cost structure rarely fits early-stage projects1.

Non-Standard Designs and Tight Tolerances

Motorcycle fasteners frequently include special head designs, undercuts, shoulders, or mixed thread specifications. These features are often driven by packaging constraints or weight reduction goals defined during the design phase. A deeper discussion of design considerations can be found in this article on designing custom motorcycle fasteners.

Development Time Pressure

Vehicle programs move fast. A delayed fastener can stop assembly trials or track testing. At this stage, responsiveness and technical clarity matter more than marginal unit savings.

How Does CNC Machining Solve Small-Batch and Non-Standard Requirements?

CNC machining removes the structural barriers that block progress during development and early validation.

Because CNC machining does not require dedicated tooling, it enables full design freedom and manageable cost for prototypes and low-volume production.

I often recommend CNC machining as the default choice until the design is fully frozen and volumes justify forming tools.

No Tooling Investment

CNC machining relies on digital programs rather than physical dies. This makes it ideal for early-stage projects where design changes are expected and irreversible tooling decisions carry risk.

Full Design Flexibility

Thread profiles, head shapes, drive features, and secondary operations are all controlled by programming. This flexibility aligns well with evolving fastener designs used in performance motorcycles2 and racing applications.

Cost Control at Early Stages

Although CNC machining has a higher unit cost than cold heading at scale, it avoids upfront tooling costs and reduces schedule risk, which often makes it more economical overall during development.

Why Is Consistent Quality Critical for Motorcycle Fasteners?

Motorcycle fasteners are small components with large consequences.

CNC machining delivers stable dimensional accuracy and repeatability across batches, which lowers assembly risk and supports traceable quality control.

In critical assemblies, quality consistency matters as much as material strength.

Dimensional Accuracy and Repeatability

Modern CNC lathes and mills can maintain tight tolerances reliably. With proper inspection plans, dimensional variation stays controlled even across multiple small batches.

Stable Quality Across Revisions

Fastener designs often go through multiple revisions. CNC machining allows the same quality standards to be applied consistently from early prototypes to pre-production runs.

Strength and Performance Considerations

Material selection and strength grading also play a major role in fastener reliability. I often reference detailed breakdowns like motorcycle fastener materials compared and motorcycle fastener strength grades explained when discussing performance requirements with engineers.

How Does CNC Machining Support Fast Prototyping and Engineering Changes?

Speed is often the deciding factor in custom fastener projects.

CNC machining allows rapid transition from CAD data to physical parts and supports immediate response to engineering change orders.

This speed directly reduces stress for engineering and project management teams.

From CAD to Parts Quickly

Once drawings are released, CNC programs can be prepared quickly. Prototypes are often shipped within days, keeping development schedules on track.

Immediate ECO Response

When dimensions, fillets, or thread lengths change, the CNC program is updated without restarting the process. This agility is difficult to achieve with forming-based methods.

Case Study: Racing Motorcycle Titanium Fastener

In one racing motorcycle project, the customer required a custom titanium shoulder bolt for suspension testing.

| Parameter | Value |

|---|---|

| Material | Ti-6Al-4V (Grade 5) |

| Quantity | 30 pcs |

| Tolerance | ±0.01 mm on shoulder |

| Thread | M8 × 1.25, cut thread |

| Lead Time | 7 days |

| Revisions | 3 design changes |

Each revision adjusted shoulder length and fillet geometry based on track feedback. CNC machining allowed continuous iteration without delays or tooling loss.

When Is CNC Machining the Right Choice for Custom Fasteners?

CNC machining is not always the final production method, but it is often the correct choice at the right time.

It is best suited for prototypes, validation builds, motorsport projects, and low to medium volumes where flexibility outweighs tooling efficiency.

Understanding how CNC fits among other processes is critical. A broader comparison can be found in this overview of common manufacturing processes for motorcycle fasteners.

Ideal Use Cases

CNC machining excels during R&D, pilot runs, and specialty motorcycle production where change is expected.

Comparison with Cold Heading

Cold heading3 offers unbeatable cost at high volume, but only after the design is stable. CNC machining bridges the gap between concept and mass production.

Procurement Decision Support

A balanced strategy often starts with CNC machining to validate performance, then transitions to forming processes once volumes increase and designs stabilize.

What Should You Look for in a CNC Machining Partner?

The machining process alone does not guarantee success.

An experienced CNC machining partner contributes engineering insight, clear communication, and production flexibility.

In my experience, successful projects depend on shared technical understanding4.

Industry Experience

Partners familiar with motorcycles and racing applications understand vibration, fatigue, and assembly constraints.

Engineering Communication

Early feedback on manufacturability prevents late-stage problems and rework.

Flexible MOQ and Export Quality Mindset

Low minimum order quantities, disciplined inspection, and export-oriented quality systems reduce sourcing risk for international customers.

Conclusion

CNC machining gives custom motorcycle fasteners a clear advantage during development by combining precision, fast iteration, and stable quality, while allowing procurement teams to control risk before committing to mass-production processes.

-

This resource will provide insights on cost management strategies specifically tailored for early-stage projects. ↩

-

This resource will provide insights into the essential features that define performance motorcycles, helping you understand their advantages. ↩

-

This resource will provide insights into cold heading's cost-effectiveness and its role in high-volume production. ↩

-

Understanding this concept is crucial for successful collaboration in projects, ensuring all partners are aligned. ↩