CNC Precision Machining

June 11, 2024 Author: TONY

HOME << BLOG

What is CNC Precision Machining?

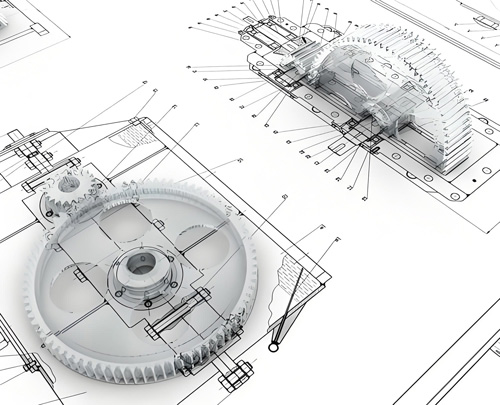

Today, our world is surrounded by rapidly evolving and complex technologies. In our daily work and life, we will see a lot of complex precision parts, such as gears and mechanical internal components, there may be a lot of people curious about how these parts are manufactured.

Well, today we will discuss with you how these precision products come about, in fact, the vast majority of precision products are actually CNC Precision Machining.

Generally speaking,CNC Precision Machining is a high-precision and high-quality mechanical manufacturing technology, with machining accuracy reaching or even exceeding 1 micrometer.

The following are the main characteristics and contents of precision machining:

CNC Precision Machining is a process of changing workpieces, mainly through the precise adjustment of the external dimensions or performance of the workpiece through machining machinery.

It includes two categories: cold working and hot working. Cold processing is usually carried out at room temperature without causing any chemical or phase changes to the workpiece; However, hot processing is carried out at temperatures above or below room temperature, which may cause chemical or phase changes in the workpiece.

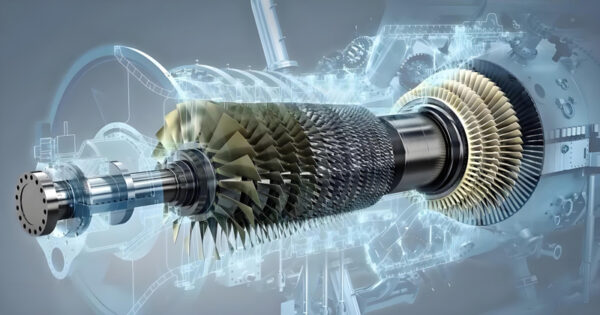

Precision machining methods mainly include precision turning, precision boring, precision milling, precision grinding, and grinding processes. These methods are achieved using precision machine tools, precision measuring tools, and measuring instruments under strictly controlled environmental conditions.

The ultra precision machining method is called ultra precision machining, which is particularly important in the aerospace industry and is used to process precision mechanical parts in aircraft control equipment, such as hydraulic pumps and pneumatic servo mechanisms. Machining on a high-precision lathe can achieve a precision of 1 micrometer and a surface roughness with an average height difference of less than 0.2 micrometers, with a coordinate accuracy of ± 2 micrometers.

Precision machining technology is a key technology in modern mechanical manufacturing process systems, characterized by high precision and high quality.

It is closely related to modern mechanical design and manufacturing technology. Through the application of precision machining technology in mechanical manufacturing, product quality can be improved, creating high benefits for enterprises, and improving efficiency and quality.

Precision machining is widely used in various fields, such as aerospace, automotive manufacturing, electronic equipment, medical devices, etc.

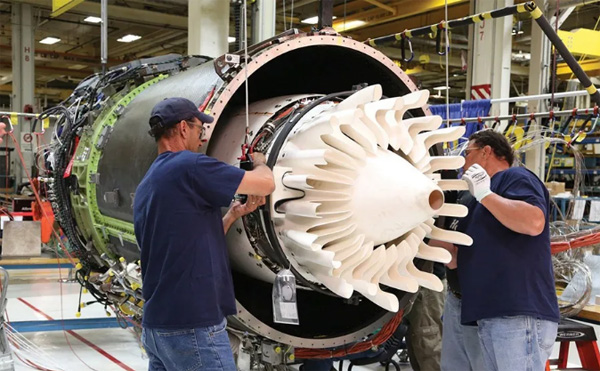

In the aerospace field, precision machining is used to manufacture key components such as aircraft engines and missile components.

The 1950s to 1980s were the pioneering period of ultra precision machining technology. The United States was the first to develop ultra precision machining technology and developed diamond tool ultra precision cutting technology.

In the 1980s and 1990s, ultra precision machining technology began to enter the early stages of civilian industrial applications. Several companies began to launch ultra precision machining equipment and began manufacturing general civilian industrial optical components.

The importance of precision machining

This is because precision machining is designed to meet the demand for high accuracy and performance in specific industries and applications. Therefore, precision machining involves not only precise control during the machining process, but also careful selection and optimization of the machining materials, tools and processes to ensure that the quality and performance of the final product meets the expected standards.

With the development of technology, precision machining is increasingly used in automotive, electronics and aerospace fields, especially in improving product quality and promoting technological innovation plays a key role.

To summarize, precision machining is a work that can only be accomplished through the cooperation of many parties.

If you have precision parts that need to be precision machined, be sure to look for a reliable CNC machining supplier to make them, because only in this way can you get the perfect workpiece as expected!

ALLIED has over 20 years of experience in precision CNC machining and a comprehensive after-sales service system. If you have any needs or questions about CNC precision machining, you can directly contact us, and we will provide the most suitable solution for you in the shortest possible time.

Contact With US

Share your needs with us, Well contact you in very short time.

Address: No.5608,Xinhua Road,Weifang,Shandong,China

Hours: 8:30a-6:00p Monday to Friday

Phone: +86 1996 3099 511

Email: quote@alliedcn.com