Choosing the wrong turning tool can lead to poor finishes, slow production, or broken tools. This wastes time and material, compromising the quality of your precision parts.

The right turning tools are chosen based on the workpiece material, the specific operation (roughing, finishing), the desired surface finish, and the CNC machine's capabilities. Proper selection balances speed and tool life.

From my first days as a machinist to now running Allied Metal, I've learned that the success of a turning job often comes down to the small piece of carbide at the tip of the tool. For engineers like David, who design parts with specific performance and finish requirements, understanding the 'why' behind a tool choice is incredibly valuable. Choosing the right turning tools is not just about matching tool to material — it’s about understanding machining purpose, surface finish requirements, and machine capabilities. This decision directly impacts the final quality of the part. From CNC machining to metal finishing and even woodturning, selecting the right tool directly affects productivity, precision, and tool life. It’s a critical decision that bridges design and creation.

What Is the Core Principle of Cutting Tool Selection?

Beyond just picking a tool that fits, what is the fundamental thought process behind proper turning tool selection for any given job?

The core principle of cutting tool selection is to find the optimal balance between productivity, tool life, and part quality for a specific material and operation.

Diving Deeper into the Selection Process

The principle of turning tool selection goes much deeper than simply finding a tool that can cut a specific material. It's a strategic process of balancing several competing factors to achieve the most efficient and effective outcome. For an engineer like David, this is where design requirements meet manufacturing reality.

The goal is to answer several key questions:

-

What is the Operation's Purpose? Are we performing a heavy roughing cut to remove a lot of material quickly? Or are we doing a light finishing pass where surface quality is the top priority? The turning tools for these two tasks are very different. Roughing requires a strong tool that can handle high forces, while finishing requires a sharp tool that can produce a clean surface.

-

What is the Workpiece Material? Is it a soft material like aluminum, a harder material like stainless steel, or a tough superalloy? The material's hardness, abrasiveness, and thermal conductivity will dictate the best cutting tool material1 (e.g., High-Speed Steel, Carbide, Ceramic) and the specific geometry of the cutting edge.

-

What are the Part Requirements? What are the specified tolerances and surface finish (Ra) values? A design requiring a mirror-like finish will need a different set of metal turning tools and turning inserts than a part where the finish is not critical.

-

What are the Machine's Capabilities? As we'll discuss later, the CNC machine's horsepower, rigidity, and speed range limit which lathe turning tools can be used effectively.

The core principle is not to find a single "best" tool, but to select a system—the tool holder, the insert, the geometry, and the grade—that provides the optimal trade-off between removing material quickly (productivity), lasting for a reasonable time (tool life), and creating a part that meets all specifications (quality).

What Are the Main Types of Turning Tools Available?

When you open a machinist's toolbox for a lathe, what different kinds of turning tools would you find, and what is each type designed to do?

Common turning tools include those for general turning and facing, profiling, grooving, threading, and parting off. They can be solid HSS or, more commonly, indexable holders using carbide inserts.

Exploring Tool Categories in Detail

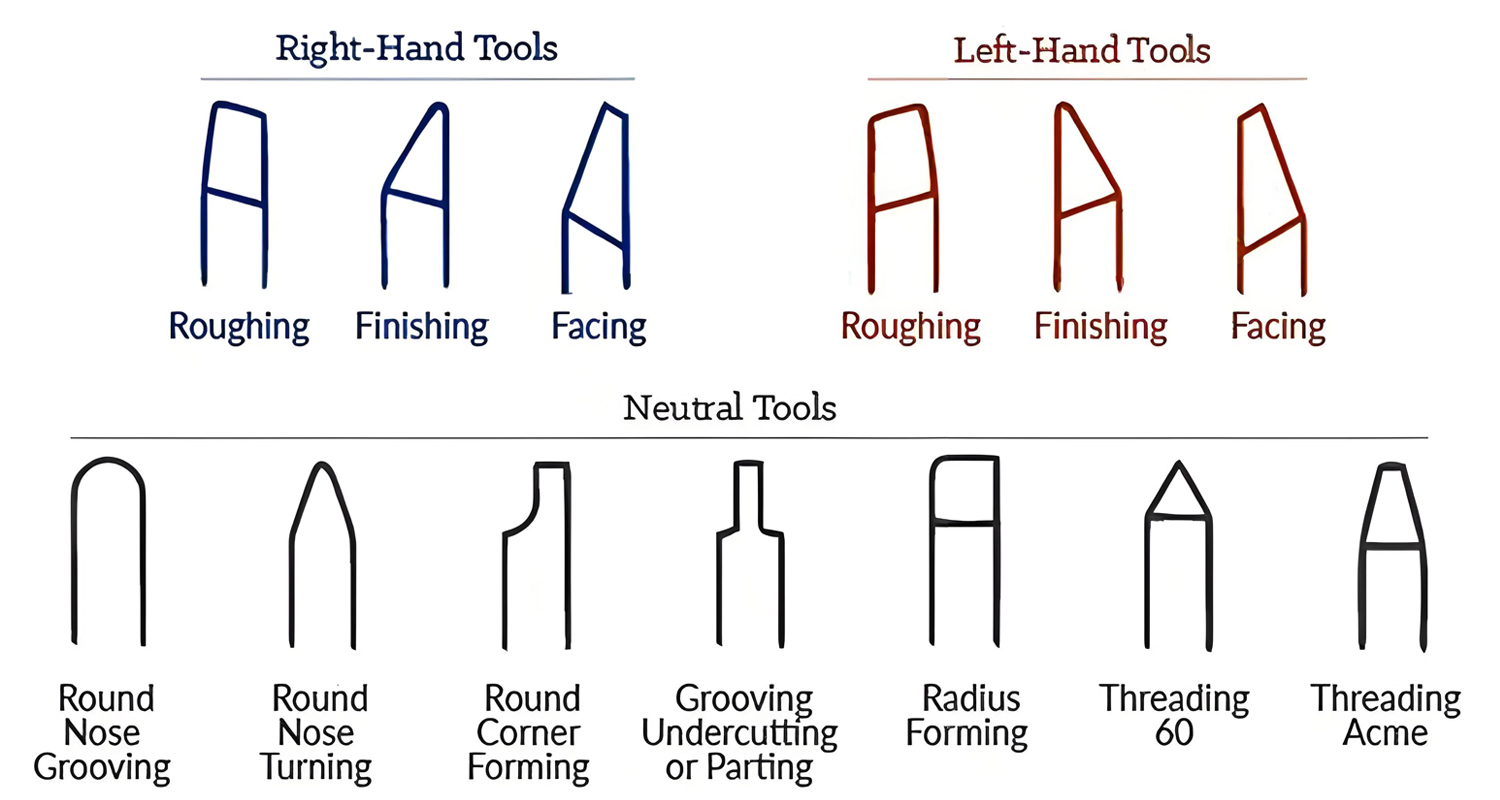

The world of turning tools is vast, with specialized designs for every conceivable operation on a lathe. They can be categorized in several ways, but for an engineer like David, understanding them by their function is most practical.

Based on Construction

- Solid Tools: These are tools made from a single piece of material, typically High-Speed Steel (HSS). They are often ground by hand for custom shapes and are common in manual machining or for special applications.

- Brazed Carbide Tools: An older style where a small carbide tip is brazed onto a steel shank.

- Indexable Turning Tools2: This is the modern standard for CNC machining. These tools consist of a reusable steel holder and a small, disposable (or rotatable) cutting insert made of carbide or another hard material. When an edge gets dull, the operator can simply index (rotate) the insert to a fresh edge or replace it. This is highly efficient and consistent.

Based on Function

The shape of the tool holder and the insert determines what it can do:

- General Turning/Facing Tools: These are the workhorses used for turning down diameters and facing off the ends of a part. A common example uses a square or rhombic insert (like a CNMG or WNMG).

- Profiling Tools3: These turning tools use inserts with a more pointed shape (like a DNMG or VNGM) that allows them to cut complex contours, tapers, and profiles.

- Grooving Tools: These have a narrow, specific-width insert designed to plunge into the workpiece and create grooves, such as for O-rings or retaining clips.

- Threading Tools: These use a pointed insert with a precise 60-degree (or other standard) angle to cut screw threads on the outside or inside of a part.

- Part-Off Tools: A long, blade-like tool used to cut the finished part off from the original bar stock.

- Boring Bars4: A type of internal turning tool used to enlarge and finish the inside diameter of a hole.

This variety of custom turning tools allows us at Allied Metal to produce virtually any rotational feature required.

How Does Your CNC Machine Choice Influence Turning Tool Selection?

Does the CNC lathe itself affect which turning tools you can use? How do machine specifications like power and rigidity impact tooling decisions?

Yes, the CNC machine is critical. Its horsepower, rigidity, spindle speed range, and tool turret type directly determine which turning tools and inserts can be used effectively and productively.

Inside Machine and Tool Synergy

Choosing the right turning tools isn't done in a vacuum. The CNC machine—the lathe or turning center—plays a huge role in the decision. A tool is only as good as the machine that wields it. For David, who values efficiency and short cycle times, understanding this synergy is key.

Machine Horsepower and Rigidity

- A CNC lathe with high horsepower and a very rigid construction (e.g., a box-way machine) can handle much higher cutting forces.

- This allows a machinist to use turning tools with stronger insert geometries (like negative rake inserts), take deeper depths of cut, and use higher feed rates. This all translates to a higher material removal rate (MRR)5 and shorter cycle times.

- On a smaller, less rigid machine, trying to use aggressive CNC turning tools would cause vibration (chatter), poor surface finish, and potentially damage to the machine. Lighter-duty tools with sharper, more positive rake geometries would be required.

Spindle Speed Range (RPM)

- The maximum RPM of the machine's spindle is a limiting factor. To achieve the correct surface speed (SFM or m/min) for a given material, especially on small-diameter parts, a high RPM is necessary.

- If the machine can't spin fast enough, you can't take full advantage of modern carbide turning tools and coatings that are designed to run at very high speeds. You would be forced to run slower, increasing cycle time.

Turret and Tool Holder Type

- The tool turret is what holds all the lathe turning tools. The style of the turret (e.g., VDI, BMT) and the size of the tool pockets determine the size and type of tool holders that can be used.

- A machine with a large, robust turret can support larger, more rigid boring bars and turning tools, which is essential for heavy-duty work.

Live Tooling and Multi-Axis Capabilities

- Modern mill-turn centers have "live tooling6," where the turning tools in the turret can also spin, allowing for secondary milling, drilling, and tapping operations.

- These machines require a whole different class of specialized tooling that combines turning and milling functions. This greatly expands capability but also requires careful tool selection.

At Allied Metal, we match the right machine to the job to ensure we can use the most efficient turning tool selection possible.

How Do You Choose Turning Tools Specifically for Metal Finishing?

Rough cutting is about speed, but finishing is about quality. What specific characteristics should you look for in metal turning tools to achieve a smooth, precise surface finish?

For metal finishing, choose turning tools with a sharp cutting edge, a positive rake angle, and a small nose radius. Specialized wiper inserts are excellent for achieving a superior finish.

How to Select the Right Finishing Tool?

When the goal shifts from rapid material removal to achieving a high-quality surface finish and holding tight dimensional tolerances, the criteria for turning tool selection change significantly. A great finish comes from a clean shearing action, not brute force.

Insert Geometry for Finishing

The geometry of the turning insert is the most critical factor.

- Sharp Cutting Edge: A finishing insert must be extremely sharp to cleanly shear the metal rather than plowing or pushing it. Edge preparation is minimal (often a light hone or just a sharp edge).

- Positive Rake Angle: A positive rake angle helps direct the chip away from the workpiece, reduces cutting forces, and minimizes heat generation. This leads to a cleaner cut and less chance of work-hardening the surface.

- Small Nose Radius: The nose radius is the small arc at the tip of the insert. A smaller nose radius (e.g., 0.4mm or 1/64") reduces cutting forces and allows for fine detail, which is ideal for a finishing pass. The trade-off is that it's a weaker edge compared to a larger radius used for roughing.

Wiper Inserts

- For the absolute best surface finish, a wiper insert is the ultimate tool. This specialized finishing insert has a small, specially shaped flat section (the "wiper") right behind the main nose radius.

- As the tool feeds along the part, this wiper flat "wipes" or smooths out the microscopic peaks and valleys (scallops) left by the nose radius.

- The incredible benefit is that a wiper insert can produce a mirror-like finish at a much higher feed rate than a standard insert. This means you can achieve an excellent finish without sacrificing as much cycle time.

Grade and Coating

- For finishing metal turning tools, machinists often choose a cermet grade or a very hard, fine-grain carbide grade.

- A slick PVD (Physical Vapor Deposition) coating, like TiN or TiAlN, is often preferred for finishing because it provides a very low-friction surface that prevents material from sticking to the cutting edge (built-up edge), which would ruin the finish.

By combining the right insert geometry, grade, and cutting parameters (high speed, light depth of cut), we can achieve exceptional surface finishes on turned components.

How Do You Choose the Correct Turning Insert for Your Tool?

The insert is the business end of an indexable tool. With so many codes and shapes, how do you decipher the options to select the right turning insert?

Choose a turning insert by its ISO code, which defines shape, clearance, and size. Then, select the appropriate chipbreaker for your operation (roughing/finishing) and a carbide grade/coating for your material.

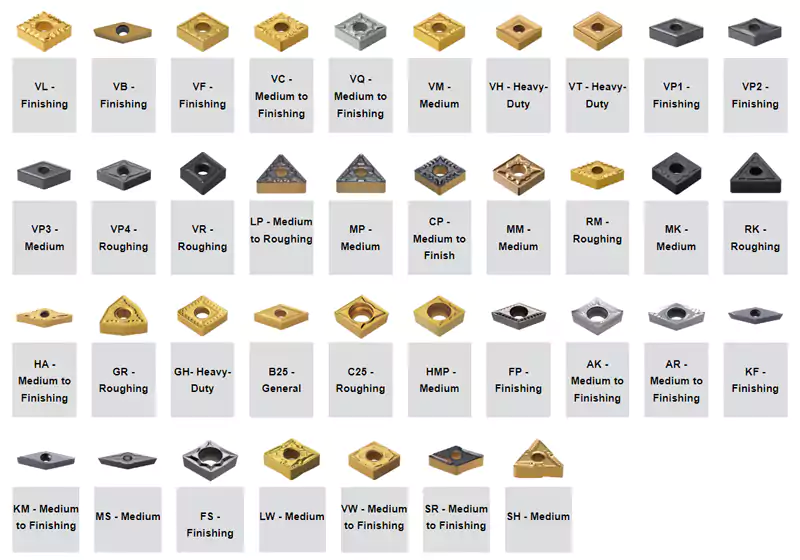

Understanding Insert Selection

Selecting the correct turning insert from a catalog full of options can seem daunting, but it's a systematic process. The industry uses a standardized ISO coding system that tells you everything you need to know about the insert's basic geometry. For every engineer, understanding this system can help him interpret tooling choices.

1. Deciphering the ISO Code

The string of letters and numbers on an insert package (e.g., CNMG 120408) is a code. Here’s a quick breakdown:

- C (Shape): The first letter defines the insert shape (C = 80° Rhombus, T = Triangle, W = Trigon, S = Square, V = 35° Rhombus). The shape determines the tool's strength and versatility.

- N (Clearance Angle): The second letter defines the clearance angle of the insert's side. N = 0° (Negative), P = 11° (Positive).

- M (Tolerance): The third letter indicates the manufacturing tolerance of the insert's size.

- G (Hole/Chipbreaker Type): The fourth letter defines the type of mounting hole and chipbreaker features.

- 120408 (Size and Nose Radius): These numbers define the insert's size (length of the cutting edge) and the nose radius (08 = 0.8mm radius).

2. Choosing a Chipbreaker

The chipbreaker is the complex molded geometry on the top surface of the insert. Its job is to curl and break the long, stringy chips produced during turning into smaller, more manageable pieces. Manufacturers offer different chipbreakers for:

- Finishing (F): Sharp, low-resistance geometry for light depths of cut.

- Medium Machining (M): A versatile, all-around geometry for moderate depths of cut.

- Roughing (R): Strong, robust geometry designed to handle heavy depths of cut and high feed rates.

3. Selecting a Grade and Coating

The grade refers to the specific recipe of tungsten carbide and cobalt binder used to make the insert, which determines its hardness and toughness. The coating (like TiAlN) is a micro-thin layer applied to the surface to increase hardness and wear resistance. Tooling manufacturers provide charts that recommend the best grade and coating combination for specific materials (e.g., one grade for steel, another for stainless steel, another for aluminum).

By systematically choosing the shape, chipbreaker, grade, and nose radius, a machinist can select the perfect turning insert for their specific job.

How Does Choosing Woodturning Tools Differ from Metal Turning?

You've learned about metal turning tools. Is it the same for wood? How does the process and turning tool selection differ for woodturning?

Woodturning tools are typically long-handled, solid High-Speed Steel (HSS) tools used for manual lathe work. Unlike carbide turning tools for CNC, they are designed to be hand-sharpened to a razor edge.

Diving Deeper into Woodturning Tool Selection

While both woodturning and metal turning involve shaping a rotating workpiece on a lathe, the tools, techniques, and machine types are fundamentally different. For an engineer like David, it's important to recognize that woodturning tools generally refer to manual tools, not CNC tooling.

Manual vs. CNC

The vast majority of woodturning is a manual craft. A skilled woodturner stands at a wood lathe and uses their hands to guide long-handled cutting tools across a tool rest to shape the wood. The process is guided by skill, touch, and sight. This is very different from CNC turning, which is fully automated.

Types of Manual Woodturning Tools

The basic set of woodturning tools is quite different from the indexable inserts used in CNC. They are simpler in form and designed for hand control.

- Gouges: These have a curved, flute-like cutting edge.

- Spindle Gouges: Used for shaping pieces between centers (like table legs).

- Bowl Gouges: Have a deeper flute and are stronger, used for shaping bowls.

- Skew Chisel: A flat chisel with an angled cutting edge. Used for creating very smooth planing cuts and fine details. It's powerful but difficult to master.

- Parting Tool: A thin, pointed tool used to cut grooves or to separate the finished piece from the waste wood.

- Scrapers: Broad, flat tools used to smooth out curves, especially inside bowls. They scrape the wood rather than cutting it cleanly.

Tool Material

Unlike modern metal turning tools that rely on carbide, traditional woodturning tools are almost exclusively made from High-Speed Steel (HSS).

- Why HSS? HSS can be ground to an extremely sharp, fine "razor" edge, which is necessary for cleanly shearing wood fibers. Carbide is harder but more brittle and generally cannot be honed to the same level of sharpness.

- Sharpening: A key skill for woodturners is constantly sharpening their tools on a bench grinder to maintain this razor edge. This is a stark contrast to the disposable or indexable nature of carbide turning tools.

CNC Woodturning

CNC wood lathes do exist, especially for production work like making baseball bats or furniture legs. These automated machines often use custom turning tools with carbide inserts, but the insert geometries are specifically designed with very sharp edges and high rake angles suitable for cutting wood, not metal.

Conclusion

Choosing the right turning tools is vital for machining success. Balancing material, operation, finish, and machine capability ensures precision, quality, and efficiency in every turned part.

-

Learn about various cutting tool materials and their specific applications to enhance your machining efficiency and effectiveness. ↩

-

Discover the efficiency and versatility of Indexable Turning Tools, essential for modern CNC machining. ↩

-

Learn about Profiling Tools and their role in creating complex contours and profiles in machining. ↩

-

Explore the function of Boring Bars in enlarging and finishing holes, crucial for precision engineering. ↩

-

Learn about MRR to optimize your machining processes and improve efficiency in production. ↩

-

Discover how live tooling enhances machining capabilities and increases productivity in modern manufacturing. ↩