1. What is CAM programming?

CAM (Computer Aided Manufacturing) programming is the use of software to convert a design into instructions that can be executed on a CNC machine. It makes the manufacturing process more efficient and precise.

The Professional CNC Machining Supplier

The Professional CNC Machining Supplier

CAM (Computer Aided Manufacturing) programming is the use of software to convert a design into instructions that can be executed on a CNC machine. It makes the manufacturing process more efficient and precise.

CAM programming utilizes specialized software to create manufacturing instructions to control machine tools to produce parts and assemblies, designed to increase productivity and ensure part quality.

The specific functions of CAM programming are as follows.

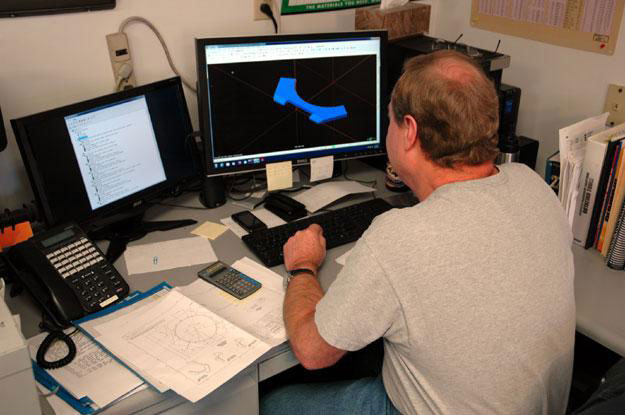

CNC (Computer Numerical Control) programming is the process of writing control programs for CNC machines. These programs guide the machine to follow preset paths and parameters.

The main task of CNC programming is to convert product design drawings into instructions that can be recognized and executed by the CNC machine. By writing a CNC program, the operator can direct the machine to follow a predetermined path and parameters.

The specific functions of CNC programming are as follows:

CNC programming improves machining efficiency and product quality, realizes complex shapes and multi-axis linkage operation, reduces the tediousness and errors of manual operation, and enhances the productivity and safety of the working environment.

It is an important part of modern manufacturing, which provides flexibility and repeatability and can be adapted to different scales of production needs.

As one of the core technologies in modern manufacturing, its application covers a wide range of aspects from precision parts processing to large-scale mold manufacturing. Through computer numerical control technology, CNC programming realizes the automatic processing of machine tools and greatly improves the production efficiency. Its high precision and high efficiency make CNC programming widely used in many industries.

The main difference between CAM and CNC programming is that they focus on different priorities and functions. CAM programming focuses more on the automation and optimization of the entire manufacturing process, including part design, process planning, tool selection, etc., while CNC programming focuses on the writing of the actual operating instructions for the machine tool.

Simply put, CAM focuses on generating manufacturing instructions, while CNC is the machine that executes those instructions.CAM is responsible for planning and designing tool paths, while CNC is responsible for controlling the machine to realize machining.

There is a growing demand for CAM and CNC programming in industry and they are widely used in automotive, aerospace, medical devices, mold making and other industries.

Efficient CAM and CNC programming can dramatically improve production efficiency, help companies respond quickly to market changes, shorten product development cycles, and enhance competitiveness.

With the continuous progress of intelligent manufacturing technology, the future CAM and CNC programming will be more intelligent and personalized, and the professional skills of programming technicians will be more demanding.

The importance of CAM and CNC programming in the manufacturing industry is reflected in a number of aspects, including improving productivity, ensuring machining accuracy, reducing labor intensity, improving flexibility and reducing production costs. These technologies not only improve manufacturing efficiency, but also ensure product quality and reduce error rates, making them an integral part of modern manufacturing.

CAM (Computer Aided Manufacturing) and CNC (Computer Numerical Control) programming software plays an important role in a number of industries, notably aerospace, automotive manufacturing, energy, medical devices and mold making.

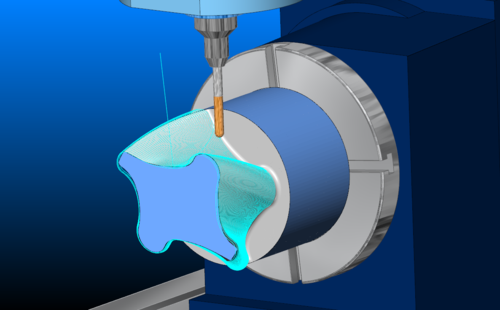

In the aerospace industry, CAM and CNC programming software provide solutions for machining high-precision and complex parts. For example, Mastercam is able to generate multi-axis cutting paths to support milling, drilling and threading of aircraft structural components, and ensure component accuracy and safety through simulation.

In automotive manufacturing, CAM and CNC programming software support the efficient machining of body parts, engine components and interior parts, significantly improving productivity and quality. By optimizing cutting paths, Mastercam helps manufacturers improve overall production performance.

In the oil, gas and nuclear energy industries, CAM and CNC programming software support a wide range of machining operations such as drilling, milling, turning and wire EDM to optimize production processes and ensure compliance with stringent quality and safety standards.

CAM and CNC programming software provide precise machining solutions in medical device manufacturing, supporting the production of complex components such as orthopedic implants and pacemakers, ensuring the safety and reliability of medical devices.

In the field of mold and die manufacturing, CAM and CNC programming software provide powerful modeling tools and machining strategies to help users efficiently design and produce various molds and dies to improve production efficiency and quality.

CAM programming and CNC programming are indispensable in modern industry and manufacturing. They complement each other to promote technological advancement and industrial development, providing efficient and accurate manufacturing solutions for various industries.

If you have the needs or questions in this regard, please feel free to contact us, we will give the fastest speed to reply, look forward to your consultation.

We use cookies to ensure that we provide you with the best possible experience on our website.