PLA (Polylactic Acid)

PLA is an environmentally friendly thermoplastic commonly used for rapid prototyping, display models and non-structural parts. It is easy to print and suitable for beginners and low-cost applications.

The Professional CNC Machining Supplier

The Professional CNC Machining Supplier

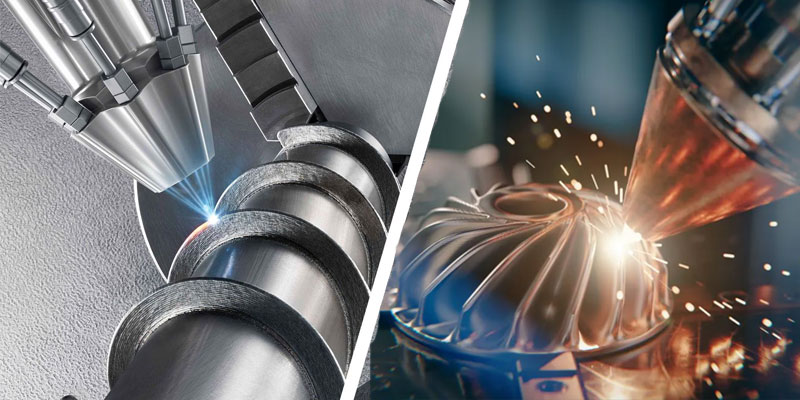

As technology advances, additive manufacturing (AM) is rapidly transforming traditional production methods. It is revolutionizing industries like aerospace, medical, and automotive, while also shaping the future of manufacturing.

Additive Manufacturing (or AM for short) is a technique for building three-dimensional objects by stacking materials layer by layer. This method is different from traditional subtractive manufacturing, which typically removes material from the raw material by cutting, milling, etc. Additive manufacturing allows complex shaped parts to be generated directly from a digital model, thus reducing material waste and increasing design freedom.

Here’s how I explain it to our new engineers:

3D printing is just one way to do AM – there are several other technologies in the toolbox.

The process is simpler than most people think:

The magic happens in step 3 – different technologies use different methods to fuse those layers together.

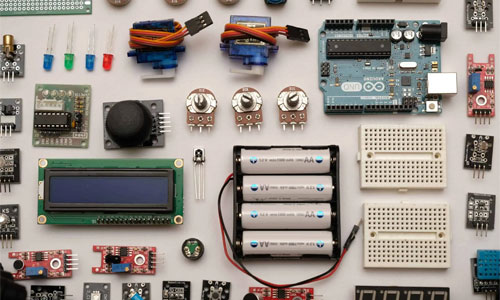

There are a wide variety of technologies for AM, which can be categorized into the following main types:

Uses an ultraviolet laser to cure photosensitive resins and is suitable for high-precision parts.

Thermoplastics are heated to the melting point and deposited layer by layer through a nozzle for prototyping and low-cost production.

Similar to SLM but uses an electron beam rather than a laser, suitable for the production of large size metal parts.

Additive manufacturing (3D printing) technology is widely used across various industries for its flexibility and precision. Selecting the right material is crucial for achieving quality prints and functionality. Below are some common materials used in AM:

PLA is an environmentally friendly thermoplastic commonly used for rapid prototyping, display models and non-structural parts. It is easy to print and suitable for beginners and low-cost applications.

ABS has good strength and heat resistance, and is widely used in the production of functional parts, such as automobile parts and electronic housings. It is more robust and suitable for the production and manufacture of mechanical parts for daily use.

PET has good transparency and chemical stability and is suitable for parts that require transparency or chemical resistance. It is commonly used in food and pharmaceutical packaging, containers and laboratory equipment.

TPU is an elastic material commonly used to make soft parts such as seals, hoses and shoe soles. It possesses elasticity and abrasion resistance for applications requiring high elasticity and abrasion resistance.

Stainless steel is commonly used in the manufacture of industrial parts that require corrosion resistance and high strength. It is widely used in aerospace, automotive manufacturing, and medical equipment such as engine components and surgical tools.

Aluminum alloy material is commonly used for structural components in aerospace, automotive and electronics due to its lightweight and high strength. It is suitable for lightweight components such as aircraft frames, automotive parts and heat exchangers.

Titanium alloy has excellent resistance to high temperatures and corrosion, and is widely used in aerospace, medical implants and high-performance racing parts. It is suitable for applications requiring extremely high strength and light weight.

Copper alloy has excellent electrical and thermal conductivity and is commonly used in the manufacture of components for electrical equipment, such as electrical connectors and heat sinks. It is also widely used in high-efficiency heat exchangers.

Aluminum ceramics have high hardness and high temperature resistance, and are widely used in high-temperature, wear-resistant applications such as engine components, gas turbine blades, and high-temperature sensors.

Alumina is a common electronic ceramic material with high strength, good electrical insulation and corrosion resistance, and is suitable for the manufacture of electronic components and electrical isolation parts.

Silicon ceramics are highly resistant to high temperatures and oxidation, and are commonly used in applications in high temperature environments, such as heat exchangers, furnaces and spacecraft components.

Zirconium ceramics are high-strength, high-temperature resistant ceramic materials commonly used in high-load applications such as industrial cutting tools, wear parts and aerospace components.

Carbon fiber reinforced plastic combines light weight and high strength and is commonly used in high performance parts for aerospace, automotive and sports equipment. It is widely used in aircraft structures, racing car parts and high-strength housings.

Glass fiber reinforced plastics increase the strength of the plastic while maintaining good rigidity, and are suitable for the manufacture of structural components such as automotive housings, construction materials and sports equipment.

Kevlar fibers have extremely high impact and temperature resistance and are commonly used in the manufacture of bulletproof equipment, racing parts and aerospace structural components.

Biodegradable plastics are suitable for environmental and medical applications and are commonly used to make biodegradable medical implants, drug delivery systems and environmentally friendly packaging.

PLA is a biodegradable material commonly used to make medical devices, personalized implants, and low-strength functional parts, and is particularly suitable for the medical and food packaging industries.

Polyvinyl Alcohol is soluble in water and is suitable for making water-soluble scaffolds and temporary support structures, and is commonly used in the biomedical field for tissue engineering and drug delivery.

Biocompatible polycarbonate has good transparency and mechanical properties and is commonly used in the manufacture of medical devices and implantables, such as pacemaker housings and medical imaging equipment components.

We had a client needing to reduce weight in drone components without sacrificing strength. Their existing aluminum bracket weighed 450g and cost $85 to machine.

Solution: We redesigned for AM using titanium alloy (Ti6Al4V) with optimized lattice structures.

Parameters:

Results:

The client now uses these brackets across their entire drone fleet, saving thousands in fuel costs annually.

Additive manufacturing is widely used across various industries, transforming traditional production with its flexibility, precision, and speed. Here are the key industries benefiting from this technology:

In aerospace, additive manufacturing is used to create lightweight, high-strength parts like engine components, structural frames, and heat exchangers. It reduces part count, lowers costs, and speeds up design iterations and testing.

In the automotive industry, AM helps create personalized parts, prototypes, and complex components. It enables the production of lightweight, high-strength parts like engine components, body parts, and interior pieces, reducing costs and production time.

It’s widely used in healthcare for custom implants, prosthetics, orthotics, and surgical tools. It allows doctors to create personalized solutions based on patient needs and helps with pre-operative planning using complex medical models.

The electronics industry uses AM for making precision housings, heat sinks, connectors, and other small electronic parts. It enhances design flexibility, reduces lead times, and supports rapid prototyping.

In consumer products, additive manufacturing is used for personalized items like jewelry, accessories, and home décor, as well as for rapid prototyping. It helps brands shorten product development cycles and respond quickly to market trends.

In defense, additive manufacturing produces high-performance weapon parts, drones, combat gear, and other critical equipment. It enables fast production of durable parts, reduces spare parts inventories, and supports tactical needs.

AM is increasingly used in education and research for teaching, experimentation, and prototyping. It provides intuitive learning tools that help students understand complex engineering and manufacturing concepts.

For batches under 1000 parts or highly complex geometries? Absolutely. For simple parts in the thousands? Traditional methods usually win.

Yes – with proper post-processing and heat treatment, AM metal parts achieve 99% density and comparable mechanical properties.

Expect 4-8μm Ra as-printed. We can get it down to 0.8μm with machining or polishing.

Typical tolerances: ±0.1mm for plastics, ±0.05mm for metals. Critical features can be machined afterward.

AM uses a variety of materials (plastics, metals, ceramics), but the options are more limited than traditional manufacturing, especially for materials that require specific strength, temperature, or corrosion resistance. However, material choices are expanding with technology advancements.

If you haven’t found the answer you need here, don’t worry—you’re not alone! Every project is unique.

👉 Check out our full FAQ page for more detailed technical answers, or better yet—reach out to me directly. I’ll tell you straight up whether AM is right for your project, no sugarcoating involved.

Additive manufacturing isn’t replacing traditional machining – it’s complementing it. For the right applications, it can slash lead times, reduce costs, and enable designs that were previously impossible.

The key is knowing when to use it and when to stick with conventional methods. That’s where 20 years of shop floor experience really pays off.

Got a tricky part that might benefit from AM? Send me the specs – I’ll give you my honest take on whether it’s the right approach.

We use cookies to ensure that we provide you with the best possible experience on our website.