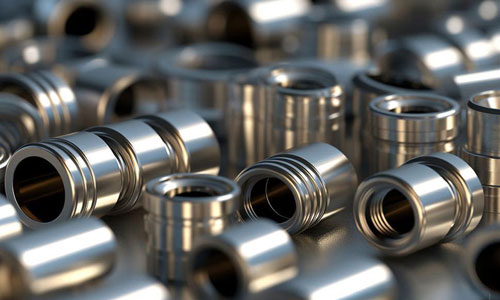

High precision and consistency:

CNC drilling machine adopts precise control system and mechanical structure to achieve micron-level machining accuracy, which ensures consistent accuracy and stable quality of each hole position in the workpiece with excellent repeatability.