Aluminum Precision Machining: 7 Types of Precision Machining Processes

- December 26, 2024

- Tony

This article covers seven key precision machining processes used in aluminum fabrication, each designed to meet the stringent demands for accuracy, efficiency, and high performance.

Whether you are looking for intricate designs, tight tolerances, or complex geometries, these machining methods are critical to achieving optimal results.

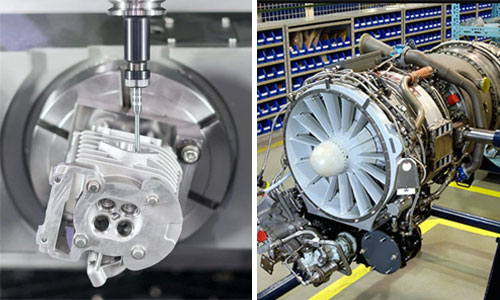

1. CNC Precision Machining

CNC (Computer Numerical Control) precision machining is the backbone of modern manufacturing, offering unparalleled accuracy and flexibility when working with aluminum. Here are the key types of CNC machining:

1.1 CNC Milling: Precise Cutting and Complex Shape Processing

CNC milling is widely used for cutting aluminum into complex shapes with high precision. The process uses rotating cutters to remove material from the workpiece, and it excels at creating intricate details, sharp edges, and fine finishes.

This process is ideal for parts like aerospace, automotive or medical parts that require detailed design and tight tolerances.

1.2 CNC Turning: High-Precision Shape Processing

CNC turning is used to produce cylindrical and rotational parts. The workpiece is rotated while a cutting tool shapes it to the required design. Aluminum’s low hardness and excellent machinability make it ideal for high-precision turning applications, especially in automotive and aerospace industries.

1.3 CNC Boring: Precision Hole Position Control

When it comes to creating precise holes with exact positioning, CNC boring stands out as an ideal solution. This process is especially vital for aluminum components that require flawless alignment and accuracy, such as engine parts and housings.

1.4 CNC Cutting: High-Efficiency Precision Aluminum Cutting

CNC cutting is used for quickly and precisely cutting aluminum sheets or blocks into specific shapes or profiles. This high-efficiency process is ideal for large-scale production of aluminum parts, ensuring both speed and precision.

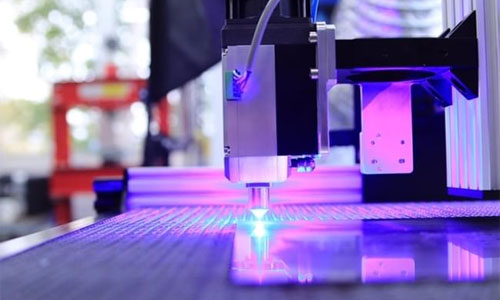

2. Precision machining: laser cutting

2.1 Principle of laser cutting

Laser cutting uses a focused laser beam to melt or vaporize material in a highly controlled manner, resulting in extremely precise cuts. For aluminum, this method allows for minimal material distortion and excellent edge quality.

2.2 Benefits of Precision Aluminum Laser Cutting

Laser cutting offers several advantages, including high precision, no tool wear, and the ability to cut intricate shapes in thin aluminum sheets. It also ensures smooth, burr-free edges, making it ideal for delicate components and designs requiring fine detail.

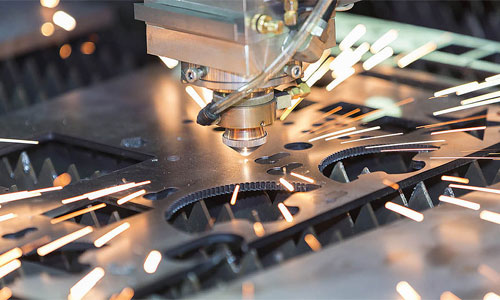

3. EDM Precision Machining

3.1 Principles and Advantages of EDM

EDM is an unconventional machining method that uses electrical sparks to wear away material. It is particularly effective for shaping complex geometries in hard-to-machine materials like aluminum alloys, providing high precision even in challenging designs.

3.2 Application of EDM in Aluminum Precision Machining

EDM is widely used for producing precise molds, cavities, and parts with intricate geometries, especially when the material’s hardness makes traditional cutting methods difficult. It is highly effective for making small holes, sharp corners, and fine details in aluminum parts.

4. Precision Stamping and Molding

4.1 Advantages of Precision Stamping Process

Precision stamping involves pressing aluminum sheets into a mold under high pressure to create specific shapes. This process is highly efficient for mass production and delivers consistent, high-quality parts with minimal post-processing.

4.2 Precision Machining: Controlling Die Forming in Aluminum

Die forming is a key component of the stamping process, ensuring that the aluminum material is precisely shaped according to the design specifications. Accurate control of the die ensures tight tolerances and the production of complex parts, making it suitable for industries such as automotive and electronics.

5. Aluminum Surface Precision Treatment

5.1 Anodizing: Improvement of Surface Hardness and Corrosion Resistance

Anodizing is a surface treatment process that enhances the hardness, corrosion resistance, and overall durability of aluminum parts. It also improves the appearance, providing a high-quality, aesthetically pleasing finish.

5.2 Spraying and Coating: Increase Surface Aesthetics and Durability

Spraying and coating involve applying protective layers to the aluminum surface. This process not only enhances the appearance but also improves wear resistance and helps protect against corrosion, making it ideal for both decorative and functional applications.

5.3 Hardening: Improvement of Wear Resistance of Aluminum Parts

Hardening treatments can be applied to aluminum to enhance its wear resistance, particularly in parts that undergo heavy usage, such as gears and mechanical components. This improves the longevity and reliability of the finished product.

6. 3D Printed Precision Manufacturing

6.1 Aluminum Applications for Additive Manufacturing

Additive manufacturing (3D printing) has transformed aluminum precision machining by making it possible to produce intricate geometries that would be challenging or impossible to create using conventional techniques. This technology is especially useful for prototyping and low-volume production of aluminum parts with intricate designs.

6.2 3D Printing Innovations for Aluminum Precision Machining

Recent advancements in 3D printing technology allow for the use of high-strength aluminum alloys in the printing process. This has opened up new possibilities for industries such as aerospace, automotive, and healthcare, where customized, high-performance parts are in high demand.

7. Milling and Grinding for Precision Machining

7.1 Application of Milling Technology in Aluminum Precision Machining

Milling is a versatile precision machining process used for shaping aluminum into a wide variety of forms. It allows for intricate features, tight tolerances, and smooth finishes, making it suitable for parts such as brackets, gears, and housings.

7.2 Advantages and Applications of Grinding Process in Aluminum Precision Machining

Grinding is often used after milling to achieve an ultra-fine finish. The process removes small amounts of material to achieve precise dimensions and surface finishes. It is especially beneficial for high-precision applications where surface smoothness and strict tolerances are essential.

8. Summary

Aluminum precision machining includes processes like CNC machining, laser cutting, 3D printing, and precision treatments, all designed to meet industry needs. These methods ensure high-quality, complex parts with excellent efficiency and accuracy. Whether in aerospace, automotive, or industrial sectors, precision machining is essential for top-quality manufacturing.