The Professional CNC Machining Supplier

High Precision Customization for Diverse Needs

CNC Machining Experts In China – One Stop All Solutions

- 24-hour Response Time

- Supply Chain Advantage

- 200+ Equipment Cluster

- 100% Quality control Inspection

Our Core Capabilities

We specialize in precision CNC milling, turning, and surface finishing services for a wide range of industries.

CNC Milling Services

Our 3, 4, and 5-axis CNC machining services produce components of any geometry with dimensional tolerances down to ±0.002″.

- 3, 4, and full 5-axis milling

- Complex geometries and prototypes

- High precision and efficiency

- Maximum part size: 1100×600×500 mm

CNC Turning Services

CNC turning with power tools combines lathe and milling functions for machining parts with cylindrical features.

- CNC turning and mill-turning centers

- High precision and flexibility

- Swiss lathes and multi-axis capabilities

- Ideal for cylindrical and rotational parts

Surface Finishing

Complete your parts with aesthetic and functional finishes. One-stop solution to ensure parts are assembly-ready.

- Anodizing (Type II & III)

- Powder Coating & Painting

- Polishing & Bead Blasting

- Electropolishing, plating, and more.

How We Work?

Streamlined process from inquiry to delivery.

Upload your CAD files. Get a quote within 24h and free design feedback.

Rapid machining of sample parts (T1) for your verification and fit-check.

Full-scale manufacturing using our 200+ CNC machines. Automated scheduling.

CMM inspection, material reports, and secure global shipping.

Customised CNC machining services we can also provide

One Shop, Complete Capabilities. From precision turning and milling to EDM and laser cutting, we have the right process for your project. Get a consolidated quote for all your machining needs.

CNC Drilling

CNC drilling punches holes in the material by rotating the tool with high precision. It is suitable for hole processing of various materials and widely used in mechanical assembly.

CNC Grinding

Precision machining with abrasive tools, suitable for improving surface finish. Generally used for surface finishing of precision parts and tools.

laser Cutting

Laser cutting is widely used for fine cutting of metals, plastics and wood as it is suitable for thin material processing with high precision and fast cutting speed.

EDM

Electrical discharge machining utilizes an electric spark to remove material,can machine hard materials. It‘s used for mold making and complex parts machining.

Why SMEs & Brands Choose Allied Metal

We understand the challenges of scaling a brand without your own production lines. Allied Metal acts as your internal manufacturing department.

Cost-Effective Tooling

Save up to 30% on mold development costs. We offer flexible payment terms for verified B2B partners.

Free DFM Analysis

Our engineers review your CAD files to suggest design changes that reduce machining time and cost.

Low Volume, High Flexibility

No massive MOQs. Start with 1 unit for testing, then scale to 50, 500, or 5000 units seamlessly.

Rigorous Quality Control

In-house CMM, Optical Projectors, and Height Gauges ensure every part meets spec.

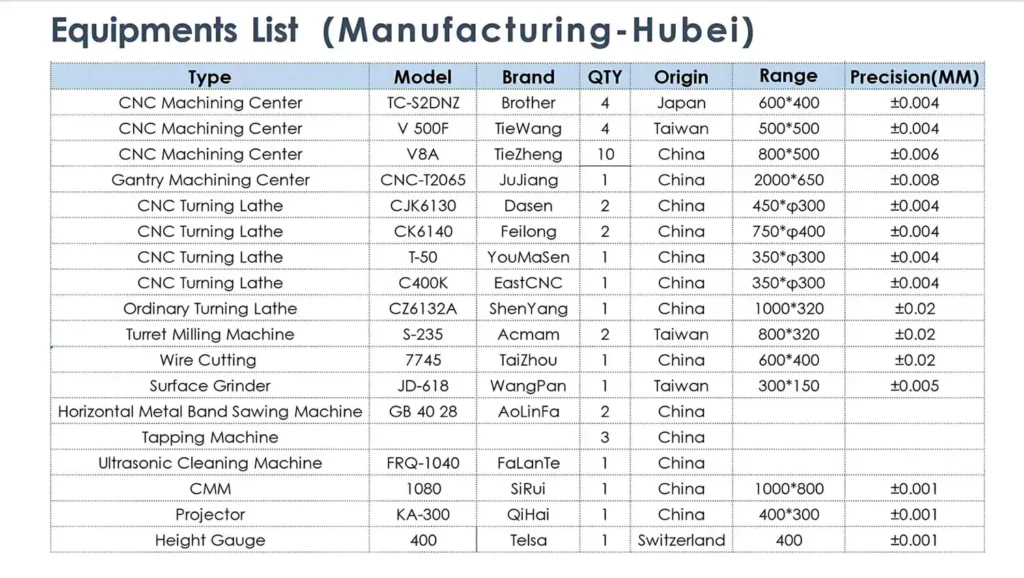

Our CNC machining equipment

We operate two fully equipped CNC machining facilities with a wide range of advanced equipment, including multiple 3-axis and 5-axis machines, as well as high-efficiency machining centers. With strong production capacity and flexible setups, we provide customized precision machining services for both small batches and large-scale orders.

Range of processing services

Ability / Parameter | CNC Milling | CNC Turning |

Maximum Part Size | 1300mm × 800mm × 300mm (51.2in × 31.5in × 11.8in) | 300mm × 500mm (11.8in × 19.7in) |

Minimum Part Size | 1mm × 1mm (0.04in × 0.04in) | 1mm × 1mm (0.04in × 0.04in) |

Minimum Feature Size | +/- 0.3mm (+/- 0.011in) | +/- 0.3mm (+/- 0.011in) |

Standard Tolerances | +/- 0.005mm (+/- 0.0002in) | +/- 0.005mm (+/- 0.0002in) |

Radii | Sharp inside corners will be radiused (rounded) | Sharp inside corners will be radiused (rounded) |

Linear Dimension Tolerance | +/- 0.005mm (+/- 0.0002in) | +/- 0.005mm (+/- 0.0002in) |

Hole Diameter Tolerance (Not Reamed) | +/- 0.005mm (+/- 0.0002in) | +/- 0.005mm (+/- 0.0002in) |

Shaft Diameter Tolerance | +/- 0.005mm (+/- 0.0002in) | +/- 0.005mm (+/- 0.0002in) |

Materials we can machining

At Allied Metal, 100+ materials are available for you to choose from, covering metals, plastics, composites, and more. Our craftsmanship is superb and we have several material certifications to ensure the high quality of each project.

CNC MACHINING PLASTIC

Over 100 CNC plastic machining machines.

Highest precision: ±0.05mm/100mm

Fastest delivery time: 5 days

Most grades plastics available Materials: ABS, PMMA (Acrylic), POM (Acetel/Delrin), Anti-static POM, PC, FR PC, PC+ABS,

PA (Nylon), PPO, PA+GF, PP, PE, PPSU, PBT, PPS, PVC, Transparent PVC, EPP, Black PEEK,

PTFE, PEI, Polyester, Bakelite, Silicone, Carbon fiber, Etc.

CNC MACHINING METAL

Over 100 CNC metal machining machines.

Highest precision: ±0.05mm/100mm

Fastest delivery time: 5 days

Most grades of metals available Materials: Aluminum Alloys (2024, 6061, 6063, 6082,

7075, ADC12), Bronze, Brass, Copper, Stainless Steel (201, 301, 304, 316, 409), Steel (Galvanized, Hot Rolled, Cold Rolled, Alloys, Low Carbon, High Carbon, Tool Steel),

Titanium Alloy, Magnesium Alloy, Zinc Alloy, Etc.

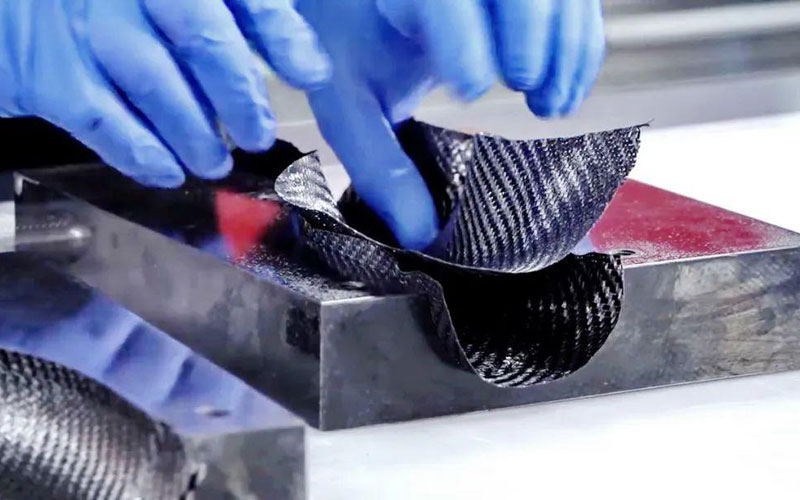

Composite Materials

Possesses CNC machine tools specifically designed for composite material processing.

Highest precision: ±0.05mm/100mm

Fastest delivery time: 5 days

Most grades composites available Materials: Carbon Fiber Reinforced Polymer (CFRP), Glass Fiber Reinforced Polymer (GFRP), Aramid Fiber (Kevlar®), Fiberglass Epoxy, Metal Matrix Composites (MMC), Ceramic Matrix Composites (CMC), Polyimide Composites, High-Strength Laminates, Reinforced Thermoplastics, Wood-Plastic Composite (WPC), Advanced Sandwich Panels (with foam/core), etc.

We will select the most suitable materials for machining according to the customer’s needs and budget to ensure the best solution for you.

Case Study: Vehicle Mounting Bracket

This precision-machined aluminum bracket for automotive applications demonstrates our capabilities in complex part manufacturing.

Aluminum Engine Bracket

Material: Aluminum 6061-T6

Process: 5-axis CNC Milling + Anodizing

Tolerance: ±0.002″ on critical features

Surface Finish: Type III Hard Anodize

Application: Automotive engine mounting system

This complex bracket required precise machining of multiple angled surfaces and tight-tolerance bore holes. Our 5-axis CNC capability allowed us to complete the part in a single setup, reducing production time by 40% compared to traditional methods.

Factory Strength Display

Hear From Our Clients

Fast Prototypes That Nailed It

"We were seriously under the gun needing rapid prototypes for a new product launch. Sent our CAD files over to Allied Metal, and boom – got perfectly machined aluminum parts back way faster than expected. The precision was spot-on, letting us move straight to testing. Lifesavers!"

Sarah K.

Lead Engineer, RDT Innovations

Complex Parts, No Sweat

"Our project demanded some tricky custom components with super tight tolerances. Allied Metal's team wasn't fazed; they handled the complex CNC machining like pros. First time quality was excellent, saving us valuable time and hassle on our stainless steel parts order."

Mike

Project Manager, APS Manufacturing

Reliable Quality, Every Time

"Finding a consistent CNC machining partner for ongoing production was tough until we found Allied Metal. They just get it – delivering high-quality machined parts on schedule, batch after batch. Their reliable service and clear communication make them a go-to supplier for us."

David

Supply Chain Manager, GTE Solutions

From Concept to Delivery: No Project Is Too Complex.

Bring us your most challenging precision part. Upload your CAD files, and we’ll handle the rest.