Table of Contents:

CNC Machining Motorcycle Parts: Explore Custom CNC Machining of Motorcycle Parts

- December 6, 2024

- Tony

Whether you are a motorcycle enthusiast or a builder, you should know that every detail of a motorcycle parts is important to improve performance.

CNC machining has revolutionized motorcycle customization, offering precision parts that boost performance and add a personal touch. In this article, we’ll explore everything you need to know about Customization of CNC motorcycle accessories.

1. Overview

1. What is CNC machining of motorcycle parts?

CNC machining refers to the process of controlling the movement of factory machinery and tools by pre-programmed computer software. It makes it easy to control complex machinery such as grinders, mills, planers and lathes.

In the motorcycle world, this technology has revolutionized the way parts are designed and manufactured, making it possible to create once unimaginably complex and precise components.

2. Common types of CNC motorcycle parts

CNC machining can produce a wide variety of shapes and sizes, ensuring the precision and durability of each motorcycle part. Common CNC-machined motorcycle parts include shafts, exhaust system parts, engine components, braking systems, hubs, flanges, gear, handlebars, suspensions, and more.

3. Common materials used for CNC motorcycle parts

Aluminum alloys are used for lightweight, high-strength components like frames and engine casings, offering easy machining and durability.

With excellent corrosion resistance, stainless steel is ideal for parts like exhaust systems and fuel tanks, ensuring long-lasting reliability in extreme environments.

Steel's strength and rigidity make it perfect for heavy-duty parts like engine mounts and transmission systems, able to withstand high loads.

ABS plastic is used for electronic components and housings, offering good mechanical properties, easy molding, and durability.

POM plastic's high melting point, wear resistance, and stability make it ideal for sliding parts and precision motorcycle components.

Carbon fiber composites are strong, rigid, and lightweight, often used for exhaust systems, high-performance parts like engine mounts and drive shafts.

4. Common Machining Processes for Motorcycle Parts

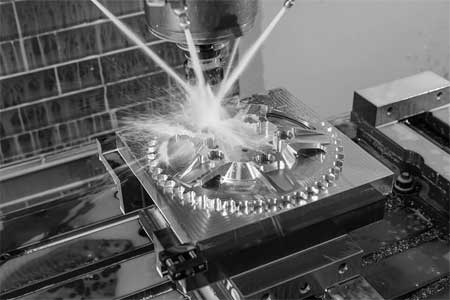

CNC Milling

Milling is the cutting of workpieces by means of a rotating tool and is used to machine motorcycle parts with complex shapes and contours.

It is suitable for manufacturing parts such as engine casings, frame brackets and gears. The milling process provides high accuracy in dimensions and surface quality and is commonly used for precision machining of motorcycle parts.

CNC Turning

Turning is to fix the workpiece on the lathe to rotate, through the tool to cut the workpiece, suitable for processing round or symmetrical motorcycle parts, such as axles, hubs and transmission system components.

Due to its high efficient machining speed and good accuracy, the turning process can easily cope with high volume production requirements.

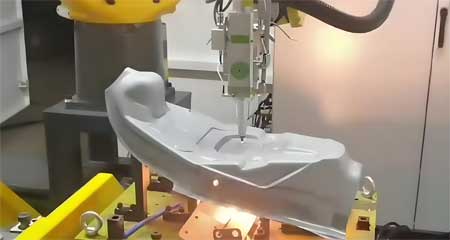

Laser Cutting

Laser cutting utilizes a high-energy laser beam to accurately cut sheet metal or other materials, and is suitable for cutting complex shapes or tiny holes.

This process is commonly used to manufacture precision housings, support parts and decorative parts in motorcycle accessories, and has the advantage of high-precision, non-contact processing.

Surface treatment

Surface treatment enhances the corrosion resistance, abrasion resistance, and appearance of motorcycle parts using physical or chemical methods. Common processes include anodizing, coating, plating, and phosphating.

Motorcycle parts that undergo surface treatment not only gain increased durability but also acquire unique cosmetic effects, such as a metallic finish or a protective anti-wear layer.

2. Why CNC Machining Motorcycle Parts?

The demand for CNC machining motorcycle parts is gradually growing, mainly reflected in the following aspects:

Two-wheeled vehicles will have a higher frequency of parts damage than four-wheeled vehicles in the course of use. CNC machining can accurately replace damaged parts to ensure that the motorcycle can restore its original performance.

Through CNC machining, customized parts with exquisite appearance and optimized functions can be produced to meet the owner’s demand for personalized appearance and performance enhancement.

Compared with traditional machining methods, CNC machining has a shorter production cycle, enabling the production of high-precision motorcycle parts in a shorter period of time, helping motorcycle manufacturers and owners get the parts they need quickly.

3. Advantages of CNC Machining Motorcycle Parts

CNC machining offers several benefits that make it the top choice for manufacturing and customizing motorcycle parts:

- Precision: CNC machining ensures precise control over the cutting process, achieving exact dimensions and shapes with minimal human error.

- Consistency: CNC machines can repeat the same program, ensuring all parts are identical and eliminating variations found in mass production.

- Cost-effectiveness: Though initial investment is high, the cost per part drops with mass production. CNC machining also lowers overall costs by reducing manual labor and errors.

- Surface Finish: CNC machining provides smooth, flawless surfaces, improving the appearance of parts and reducing friction for longer life.

- Material Compatibility: CNC machining works with various materials, including metals, plastics, and composites, ensuring accurate cuts, drilling, and engraving for different part needs.

- Design Flexibility: CNC allows for complex shapes and customized designs to meet specific performance and aesthetic requirements.

4. How to machine motorcycle parts most efficiently?

To achieve efficient machining of motorcycle parts, it’s crucial to choose the right machining method and outsourcing service provider. CNC machining offers high precision and efficiency, but the right process and equipment selection can further enhance productivity.

Selecting the Right Process

Choosing the appropriate machining process based on the material and functional requirements is key. For example, aluminum alloy handlebars may require milling and turning, while complex engine parts might need a combination of 3D printing and CNC machining.

Choosing the Right Outsourcing Partner

Partnering with a professional CNC machining service provider allows you to leverage advanced equipment and technology. This can reduce your own investment in machinery and operating costs while ensuring high-quality production of parts.

5. How to find a good CNC machining outsourcing service provider?

To improve the efficiency and quality of your motorcycle parts, consider these key factors when choosing a CNC machining provider:

- Experience and Expertise: The CNC machining service supplier should have extensive machining experience and the ability to handle complex part designs.

- State-of-the-Art Equipment: Look for a machining service provider with state-of-the-art CNC machine equipment and the ability to machine a wide range of materials and shapes.

- Lead Time and Capacity: Choose a provider with quick lead times and strong production capacity to avoid delays.

- Quality Control: Ensure the provider has a solid quality control system to meet accuracy standards and minimize rework.

If you are looking for a CNC machining outsourcing service provider, then Allied Metal is the one to trust!

Allied Metal is a leading provider of outsourced CNC machining services with online customization. With state-of-the-art CNC lathes, CNC mills, and 5-axis CNC machines, we ensure on-time delivery of high-quality products to meet a wide range of customer needs.

6. Summary

CNC machining offers motorcycle manufacturers and owners precise, efficient, and customizable solutions for part production. It enhances both the accuracy and appearance of motorcycle components, with fast turnaround times. Choosing the right outsourcing provider ensures efficient, high-quality machining, boosting performance and aesthetics. Whether replacing or upgrading parts, CNC machining is the ideal choice.