CNC machining vs. Injection molding vs. 3D printing: How to choose the best way for parts processing?

- December 5, 2024

- Tony

As we all know, CNC machining, injection molding and 3D printing are three of the most popular technologies for parts machining today. Although there is technological overlap between these three methods, they each have their own unique advantages and application scenarios.

So, when you have a part that needs to be machined? How do you choose between these three machining methods?

1. CNC Machining

CNC machining is also known as subtractive manufacturing. It is a machining method that removes material from a solid material to ultimately form the desired material through the use of computer-controlled cutting tools.

Advantages of CNC machining

- High Accuracy and Surface Quality: CNC machining achieves up to 0.01mm precision and 0.005mm repeatability, ideal for parts with fine dimensions and complex shapes, ensuring a smooth surface.

- Wide Applicability: CNC machining works with a variety of materials, including metals, plastics, and ceramics, and is suited for low to medium-scale production.

- High Efficiency: It reduces maneuvering time, shortens empty travel, supports multiple processes in one setup, and minimizes part transfer and adjustment times.

- Automation: The process is fully automated, requiring the operator only to change tools and load/unload workpieces, mainly supervising machine operation.

- Adaptability and Flexibility: CNC machining adjusts to different part requirements, making it perfect for single pieces, small batches, and prototypes.

- Modern Production Management: Digital management allows for accurate work hour calculations and easy integration with CAD/CAM systems to boost efficiency and streamline production.

Applicable Scenarios:

- Multi-species, Small-Lot Production: Ideal for new product development and varied production needs.

- Complex Part Processing: Suitable for complex 3D surfaces, especially in mold manufacturing.

- High-Precision Requirements: Meets the precision needs of aerospace, automotive, and other industries, ensuring tight tolerances and accuracy.

Material Selection and Machining Accuracy in CNC Machining

CNC machining is suitable for metal parts (e.g. aluminum, steel, stainless steel, etc.) that require high precision. Very fine surface finishes and accurate dimensional tolerances can be achieved through precision tool cutting.

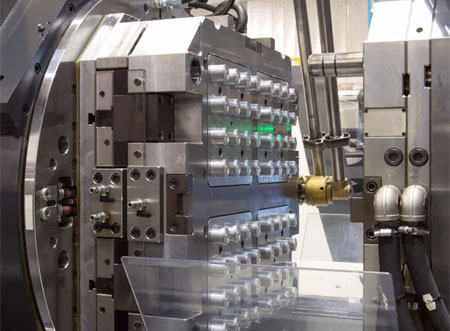

2. Injection Molding

Injection molding is a widely used manufacturing process that involves injecting heated molten plastic or metal powder into a mold. Under controlled temperature and pressure, the material cools and solidifies to form the desired products or components.

Advantages of injection molding

- High efficiency: Injection molding is ideal for mass production, with short cycle times and quick turnaround to meet large-scale demands.

- Consistent quality: Products are highly precise, stable, and suitable for applications with strict quality requirements.

- Automation-friendly: The process is easily automated, making it perfect for mass production with minimal manual intervention.

- Versatile: It can process a wide range of materials, including both thermoplastic and thermosetting plastics.

- Flexible: Molds offer flexibility in material and color, accommodating diverse product needs.

Injection Molding Application Scenarios

- Mass production: It is especially suitable for mass production and can manufacture a large number of identical parts in a short period of time.

- High cost-effectiveness: the one-time mold investment is large, but the production cost is relatively low, suitable for long time production.

- High production efficiency: high degree of automation, can complete the production of parts in a relatively short period of time.

Material selection and application areas of injection molding

It is usually used for mass production of plastic parts. Common plastic materials such as polyethylene, polypropylene, ABS and so on. This technology is widely used in the fields of plastic products, automobile parts, electronic appliances, daily necessities and so on.

3. 3D Printing

3D printing is an additive manufacturing technology that creates parts by stacking materials (e.g., plastics, metals, resins, etc.) layer by layer.

Advantages of 3D Printing

- Infinite Design Space & Easy Complex Shapes: 3D printing enables the creation of complex shapes and internal structures that traditional methods can’t easily achieve.

- No Assembly Needed: 3D printing creates complete parts in one step, eliminating the need for assembly and reducing errors.

- Minimal Material Waste: The additive process uses only the required material, reducing waste and improving efficiency.

- Variety of Materials: 3D printing supports a wide range of materials, allowing for custom solutions to meet specific needs.

- High Precision & Accuracy: 3D printing offers precise reproduction of designs, ensuring quality and consistency in every part.

Application Scenarios of 3D Printing

- Complex geometries: 3D printing easily produces intricate structures and fine details that are challenging for traditional machining.

- Rapid prototyping: It quickly turns designs into physical models, ideal for testing and speeding up product development.

- Small batch production: Without molds, 3D printing is cost-effective for producing complex parts in small quantities.

- Customization: It supports personalized designs, ideal for custom medical devices and accessories.

- Quick delivery: Printing directly from digital files significantly shortens production and delivery times.

- High complexity and small batches: 3D printing efficiently produces complex, low-volume parts at lower costs.

4. Comparison of Processing Methods

Feature | CNC Machining | Injection Molding | 3D Printing |

Cost | High upfront, best for small to medium batches. | High mold cost, low cost for large batches. | No mold cost, higher material cost for small batches. |

Efficiency | Moderate, for small to medium batches. | High, ideal for large batches. | Fast, great for prototypes and small batches. |

Accuracy | High, for complex shapes. | High, but not for very complex shapes. | Varies, good for complex shapes but lower precision. |

Materials | Metals, plastics, ceramics, etc. | Mainly plastics and composites. | Plastics, metals, resins, ceramics, etc. |

Design Flexibility | Flexible, good for custom designs. | Limited by mold design. | Very flexible, can make complex designs. |

Production Time | Longer, especially for complex parts. | Long, but fast for large batches. | Very fast, ideal for prototypes and small runs. |

Surface Quality | Smooth, may need post-processing. | Smooth, may need secondary processing. | Rough, usually requires post-processing. |

5. How to choose the right way of machining parts?

The following key factors can be taken into consideration when choosing the most suitable method of machining a part:

Machining Needs

- High precision metal parts: CNC machining is ideal.

- Large-volume plastic parts: Injection molding is better.

- Complex prototypes or small-volume customization: 3D printing is suitable.

Production Scale and Cost

- High-volume production: Injection molding lowers the cost per part.

- Small quantities or prototypes: CNC machining or 3D printing are more cost-effective and avoid mold investment.

Machining Time and Production Cycle

- CNC machining and injection molding take longer to produce.

- 3D printing is fast and ideal for urgent prototypes.

Precision and Post-processing

- CNC machining offers high precision for detailed parts.

- 3D printing’s precision varies by technology, with complex designs needing post-processing.

Design Flexibility and Optimization

- 3D printing and CNC machining allow more flexibility with complex designs.

6. How to choose a machining service provider?

Choosing the right parts machinist is critical to the success of your project. The following are a few key points to consider when selecting a processor:

- Selecting an experienced and technically capable supplier

- Evaluate the processor’s capacity and equipment

- Mode of cooperation and communication with the processor

- Importance of customer feedback and case studies

- Long-term cooperation and comprehensive cost evaluation

7. Summary

Overall, the selection of the most suitable machining method should take into account a number of factors, including the material, function, appearance requirements, production lead time, and budget of the part. Understanding the advantages and disadvantages of each machining method will help you make more cost-effective and productive decisions for different needs.