Finishing

Finishing focuses on improving the accuracy and quality of the workpiece, including its dimensions, surface finish, and shape. It typically involves precise techniques like CNC cutting, grinding, or polishing.

The Professional CNC Machining Supplier

The Professional CNC Machining Supplier

Deburring might seem like a small step in manufacturing, but it’s a game-changer for part quality, safety, and performance. In this guide, we’ll break down everything you need to know about deburring—from why it matters to how it’s done—with insights straight from the shop floor. Whether you’re a procurement manager, engineer, or designer, this is your go-to resource for making informed decisions on part finishing.

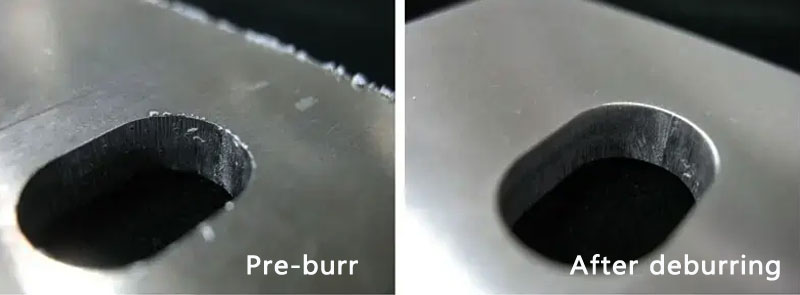

Deburring is the process of removing those pesky, sharp edges—called burrs—that form on metal surfaces during machining. Think of it as smoothing out the rough spots so parts fit together perfectly and operate safely.

A burr is primarily a protruding edge formed during machining when contact between the tool and the workpiece causes a localized tear or deformation of the metal material.

Common machining methods, such as CNC machining, casting or stamping, have the potential to create burrs on the edges or holes of the workpiece. Especially in harder materials, deburring becomes more difficult.

Burrs can be categorized into several types based on their cause and appearance:

Although burrs may seem insignificant, they are potentially harmful to the performance, appearance and safety in use of workpieces.

Skip deburring, and you’re asking for trouble. Here’s why:

We recently worked with a client producing aluminum engine mounts for automotive applications. The parts, made from 6061 aluminum with dimensions of 120mm x 80mm x 25mm, had cutting burrs up to 0.3mm high on drilled holes. During assembly, these burrs caused misalignment in bolt fittings, leading to a 15% rejection rate and delayed deliveries.

Solution: We implemented mechanical deburring using a brush wheel attachment on their CNC mill. Parameters included a spindle speed of 3000 RPM and feed rate of 500 mm/min. The process took under 2 minutes per part.

Results:

This case shows how a simple deburring step can save time, money, and reputations.

Although both processes involve surface preparation, they have different purposes and methods.

Finishing focuses on improving the accuracy and quality of the workpiece, including its dimensions, surface finish, and shape. It typically involves precise techniques like CNC cutting, grinding, or polishing.

Deburring removes sharp edges or protrusions left from machining to ensure the part is safe for assembly and use. Unlike finishing, this process doesn’t require high precision but is crucial for edge safety.

As a key step in the finishing process, deburring eliminates sharp edges, ensuring parts are safe, functional, and ready for assembly or further use.

There are several methods for removing burrs, and the choice of the appropriate process depends on the material, shape, and application requirements of the workpiece.

This method uses equipment such as sanders and grinders to eliminate burrs. It is often preferred for large workpieces or when significant burr removal is needed.

Hand tools like wire brushes, grinding stones, and deburring knives are used for this process. It’s typically employed in small batch production or for fine finishing on intricate parts.

Chemical solutions are applied to dissolve burrs, making this technique suitable for parts with complex shapes. However, material compatibility is a key consideration.

An electrolytic reaction is used to dissolve burrs, offering high precision for complex parts. This method is commonly applied to high-precision components.

Burrs are removed by impacting the workpiece surface with a jetted medium, such as sand, glass beads, or abrasive particles. Jet removal is ideal for castings or parts with high surface hardness.

Common tools for burr removal in CNC machining include:

This tool is designed to precisely remove burrs from the edges of workpieces, featuring a specialized cutting edge that enhances both efficiency and accuracy.

Brush wheels are effective for removing surface burrs without damaging the workpiece, making them ideal for light burr removal.

Abrasive belts use friction to remove burrs and are suitable for more complex workpieces that require higher precision.

Abrasive discs work by rotating rapidly to smooth surfaces and remove burrs, commonly used for fine machining and parts with stringent surface finish requirements.

These tools significantly improve burr removal efficiency, especially for CNC machining that demands high precision and quality.

Deburring is not just a surface treatment; it directly affects part assembly, service life, and operational safety. Understanding the various techniques and tools for edge removal helps you make informed choices during manufacturing, ensuring high product quality.

We use cookies to ensure that we provide you with the best possible experience on our website.