Cast iron parts machining

High-performance CNC machining services for cast iron parts!

Durable & Cost-Effective!

- Source Factory

- Reasonable price

- Certified Materials

- Timely delivery

Our Cast Iron Parts Machining Services

Cast Iron — Material Introduction

Cast iron is a family of ferrous alloys known for excellent damping characteristics, good wear resistance, and high compressive strength. Its machinability and cost-effectiveness make it a preferred material for housings, bearing supports, pump casings, and many industrial components. Allied Metal machines a broad range of cast iron grades to supply both prototypes and production volumes.

Why choose cast iron for CNC machining?

- Good machinability — cuts faster than many steels with stable tool life.

- Excellent vibration damping — ideal for rotating assemblies and housings.

- Cost-efficient raw material for medium- to large-sized parts.

Key material finish options

Material Properties of Cast Iron

Key characteristics that make cast iron ideal for precision machining

Cast iron exhibits excellent tensile strength and can withstand high temperatures and pressure without breaking or deforming.

Easy to machine with proper tools, allowing for complex geometries and precise tolerances in finished components.

Superior ability to absorb vibrations, making it ideal for machine bases and other applications where stability is critical.

Maintains strength at high temperatures, suitable for engine components and industrial machinery.

Exceptional resistance to compression forces, ideal for structural components and load-bearing applications.

Excellent resistance to abrasion and wear, ensuring long service life even in demanding conditions.

Common Types of Cast Iron

Gray Cast Iron

The most common type, known for its graphite flakes that provide good vibration damping and thermal conductivity. Ideal for engine blocks and machine bases.

Ductile Cast Iron

Featuring nodular graphite cast iron for enhanced strength and machinability. Ideal for precision CNC shafts and gear components requiring impact resistance.

White Cast Iron

High carbon, low silicon content; high hardness, wear-resistant but highly brittle. Suitable for machining wear-resistant and load-bearing components.

Malleable Cast Iron

Malleable cast iron, due to its combination of strength, ductility, and wear resistance, has replaced steel in various applications across multiple industries.

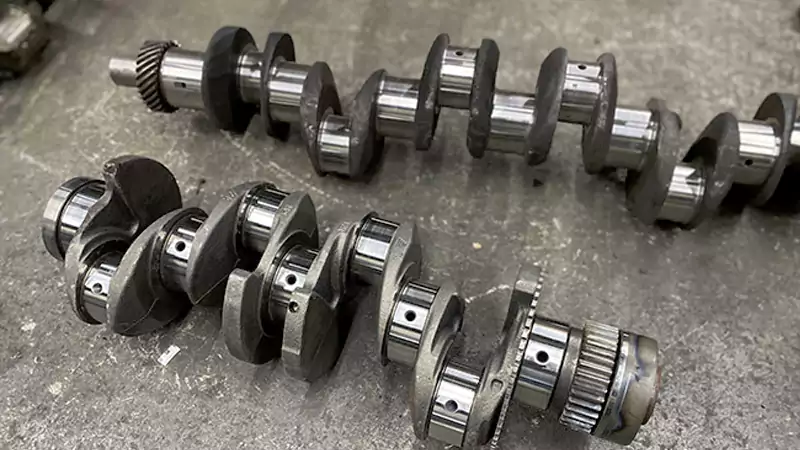

Commonly Machined Cast Iron Parts

Cast iron is commonly used to make the following parts, and is especially suited for components that require high strength, wear resistance, and vibration dampening properties:

- Gears

- Gearbox Housings

- Pump Casings

- Bases

- Pulleys and Bushings

- Engine blocks

- Support frames

- Brake discs

- Pipe connectors

- Valve Bodies

- Agricultural Equipment

- Custom Non-Standard Parts

Case Study

We specialize in machining cast iron parts.

Industrial Generator Engine Block

A leading manufacturer of power generation equipment requires a robust engine block for its new series of diesel generators. This component must deliver high stability to minimize vibration, feature precision cylinder bore machining to ensure engine efficiency, and enable cost-effective production to compete in a highly competitive market.

- Material: Gray Iron (Class 40 / GG25)

- Key Tolerances: Cylinder Bore Diameter: ±0.015 mm

Head Deck Flatness: 0.05 mm over 500 mm

- Machining Processes: 5-Axis CNC Milling, Precision Boring, Honing

Result: Delivered a 15% cost saving over previous supplier and reduced engine vibration by 10%.

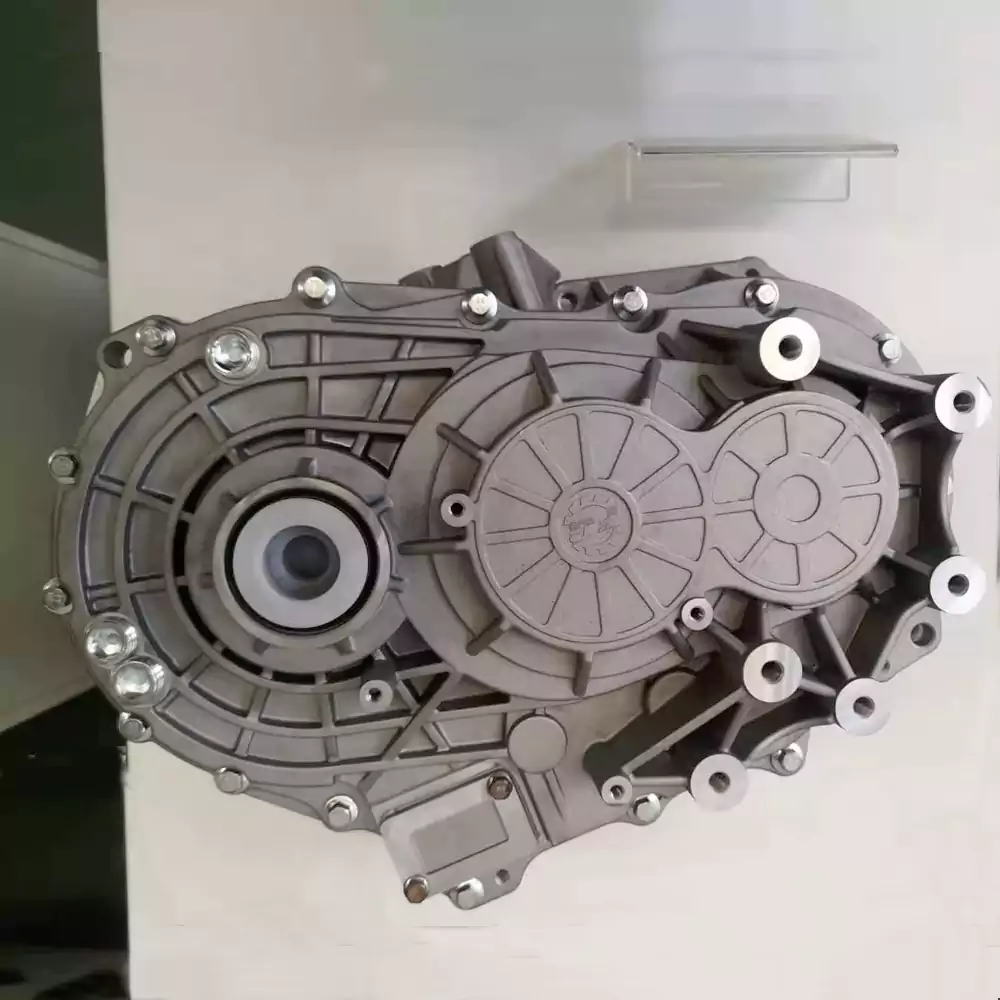

Electric Vehicle Transmission Housing

We manufactured 500 units of a complex transmission housing for an electric vehicle manufacturer. The component required precise machining of multiple mounting surfaces, bore holes, and intricate internal passages for lubrication and cooling.

- Material: Ductile Iron (Grade 65-45-12)

- Dimensions: 420mm × 320mm × 240mm

- Tolerance: ±0.05mm on critical features

- Surface Finish: Ra 1.6μm on mating surfaces

- Machining Processes: 5-axis milling, precision boring, tapping, honing

Results: The client reported a 15% reduction in assembly time due to the precision of our components and a 0% defect rate during their quality inspection process. The project was delivered on schedule and within budget.

Our Machining and Inspection Capabilities

Machining Capabilities

With 2 factories and over 200 machines including 5-axis CNC, we offer CNC milling, turning, mill-turn, and more. From rapid prototyping to mass production, with free DFM advice.

- CNC Milling & Turning

- 3D Printing

- Surface Treatments

- Flexible Small Batch Production

Inspection Capabilities

Imported high-precision equipment ensures quality: CMM, material testers, optical projectors, height gauges. We maintain strict quality control for reliable delivery.

- Coordinate Measuring Machine (CMM)

- Material Testing Instruments

- Optical Projectors

- Height Gauges

Common Cast iron Parts Machining Methods

Cast Iron Parts Machining Methods Comparison:

Machining Method | Features | Applications | Tolerances | Surface Finish | Cost |

CNC Turning | Ideal for cylindrical parts, high precision, efficient production | Mechanical parts, automotive components | ±0.01 mm | Smooth (Ra 0.8-1.6 µm) | Medium |

CNC Milling | Multi-axis machining for complex geometries | Aerospace, molds, mechanical components | ±0.01 mm | High quality (Ra 0.8-3.2 µm) | Medium |

3D Printing | Layer-by-layer manufacturing, suitable for prototypes and complex parts | Prototypes, complex geometries | ±0.01 mm | Adjustable, rough to smooth | Low to medium |

Rapid Prototyping | Quick production for testing and prototyping | Design iterations, test samples | ±0.01 mm | Variable | Low |

Sheet Metal Fabrication | Suitable for large, thin parts with bending and cutting | Enclosures, brackets, panels | ±0.5 mm | Variable | Low |

Casting | Mass production of complex shapes, suitable for durable parts | Engine housings, mechanical components | ±0.01 mm | Medium (Ra 6.3-12.5 µm) | Low |

Brief Explanation of Cost Comparison:

- CNC Turning and CNC Milling:

High precision, moderate cost, suitable for high-demand precision machining. - 3D Printing:

Ideal for small batch production and complex parts, low upfront cost but higher for mass production. - Rapid Prototyping:

Lowest cost, ideal for quickly validating design concepts and prototypes. - Sheet Metal Fabrication:

Good for large-sized or thin parts, lower cost, efficient for mass production. - Casting:

Best for large quantities and complex shapes, lowest per-unit cost, though initial tooling can be expensive.

- CNC Turning and CNC Milling:

This comparison helps you choose the most suitable machining method based on your project’s requirements and optimize your costs accordingly.

Materials

100+ materials can be freely selected to meet your customized processing needs!

Metals

Metallic materials are rugged and offer excellent strength and durability.

Plastics

Lightweight and flexible, used in a wide range of industries.

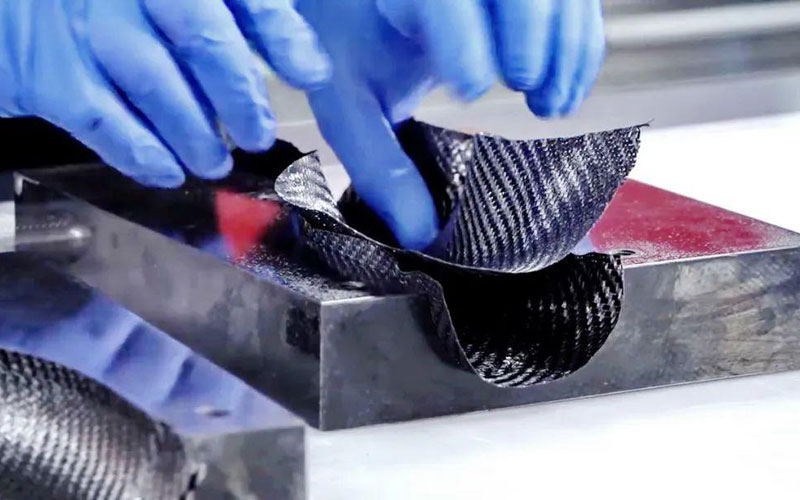

Composites

High-performance materials that combine strength and lightweight.

FAQ

Consider factors like strength, corrosion resistance, weight, and cost. We can help guide you based on your specific requirements.

Reduce cracks by controlling cutting parameters and using high quality coolant.

Improve surface finish by using proper machining methods and tool selection.

Cast iron is hard and easy to wear tools, but we use advanced equipment and appropriate tools to ensure quality.

Depending on the complexity of the part, our efficient process ensures timely delivery.

Post-treatments such as deburring and grinding are usually required to improve durability and finish.

Contact us to start your next cast iron part machining!

Upload your drawings and specifications for a fast, accurate quote on cast iron machining services.