Materials

Steel Parts Manufacturing Services

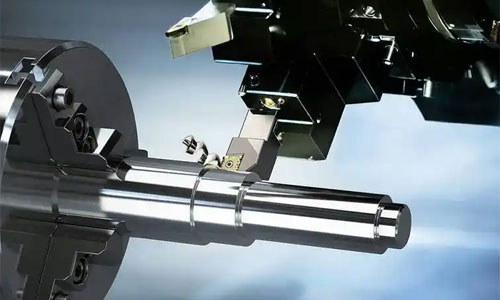

High-precision CNC machining in steel

From fast prototypes to reliable volume runs

- 2 Manufacturing sites

- 200+ CNC machines

- Reasonable price

- Certified Materials

- Timely delivery

Steel Material Properties

Understanding the advantages of steel for CNC machining applications

Machinability

Steel offers good plasticity and toughness, allowing it to be easily machined into complex parts with tight tolerances for various industrial needs.

High Strength

With strength ranging from several hundred to several thousand megapascals, steel components provide durability and reliability in demanding applications.

Stable Quality

Steel offers uniform properties with high safety and reliability, making it ideal for high-strength uses and as an alternative to other joining methods.

Good Sealing

Welded steel parts can be completely airtight, making them ideal for hydraulic cylinders, pipelines, and high-pressure vessels requiring excellent sealing.

Common types of materials used to make steel parts manufacturing

We work with a wide range of steel alloys to meet your specific requirements

Includes low carbon, medium carbon and high carbon steels, widely used in construction and general mechanical engineering.

Contains elements such as chromium and nickel for better corrosion resistance and is commonly used in food, chemical and medical fields.

Specific alloying elements are added to enhance specific properties, such as heat resistance, toughness and strength, and are commonly used for high loads and extreme environments.

With high hardness and wear resistance, they are used in molds and cutting tools.

Type | Characteristics | Strength | Corrosion Resistance | Common Grade Codes | Application Fields |

Carbon Steel | High strength, low cost | Medium | Low | A36, C45 | Construction, mechanical parts |

Stainless Steel | Excellent corrosion resistance | High | High | 304, 316 | Medical, food processing, chemical industry |

Alloy Steel | High strength, heat resistance, corrosion resistance | High | Moderate | 42CrMo, 20CrMnTi | Aerospace, automotive, marine industry |

Tool Steel | High hardness, wear resistance | Very High | Low | D2, O1 | Cutting tools, mold manufacturing |

Spring Steel | High elasticity, good toughness | High | Low | 65Mn, 55SiMn | Springs, shock absorbers |

This table shows the characteristics and application areas of several common steels to help you select the best material for your specific needs. For a quote or any other material related questions, please feel free to contact us directly or send us an email:quote@alliedcn.com

Common Applications

We offer professional Steel CNC machining solutions and comprehensive Steel Parts Manufacturing Services for various industries, ensuring precision, reliability, and high performance in every component.

Automotive Components

Precision engine parts, transmission components, suspension systems, and custom automotive fittings manufactured to exact specifications.

Industrial Machinery

Durable parts for manufacturing equipment, conveyor systems, hydraulic components, and heavy-duty machinery with strict tolerance requirements.

Medical Equipment

Precision components for diagnostic devices, surgical tools, and medical equipment with biocompatible finishes and strict quality control.

Examples of steel parts manufacturing

Steel has important applications in various fields due to its excellent mechanical properties and wide range of uses. The following are common custom machined steel parts.

- Gears

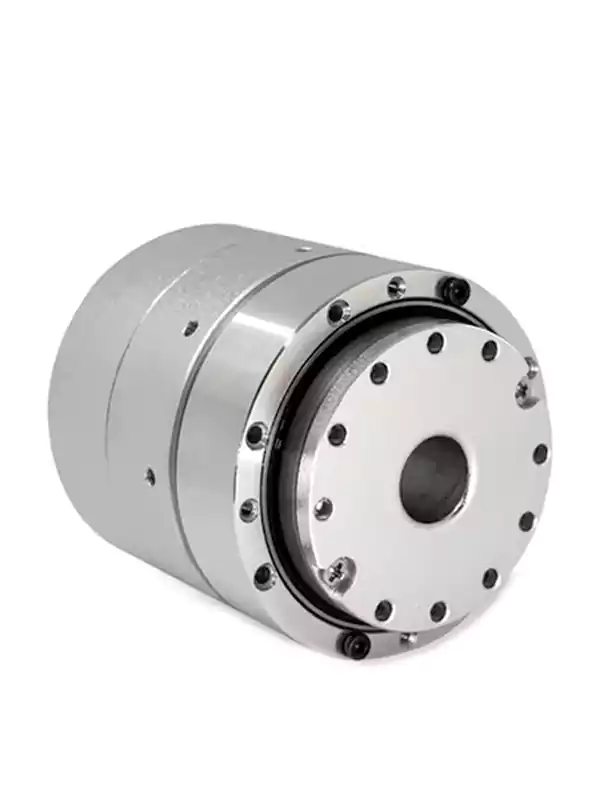

- Bearings

- Pins

- Sprockets

- Connecting rod

- Frame

- Valve cover

- Drive shaft

- Spring holder

- Machine bracket

- Pulley

- Hydraulic cylinder

- Adjusting bolt

- Brake disk

- Clamp

- Guide rail

- Fan blade

- Hydraulic valve body

- Locking ring

- Fasteners (bolts, nuts)

Case Studies

Our Steel CNC Machining Project Showcase

Case Study 1: Automotive Suspension Knuckle

For a performance electric vehicle supplier.

The client required a lightweight yet incredibly strong suspension knuckle to handle high cornering forces. The complex geometry needed to be machined from a single piece of forged alloy steel to ensure maximum reliability and safety.

Material:

Forged 4140 Alloy Steel

Finishing:

Zinc Plating for Corrosion Resistance

Key Tolerance:

Bearing Bore Diameter: ±0.005 mm

Machining Process:

5-Axis CNC Milling

Outcome: Our 5-axis machining strategy allowed us to produce the complex part in a single setup, ensuring perfect concentricity and reducing lead time by 30%. The final part exceeded the client’s strength and weight targets.

Case Study 2: Medical Device Actuator Housing

For a leading surgical robotics company.

A client required a high-precision actuator housing for a new robotic-assisted surgical arm. The component needed to be biocompatible, corrosion-proof to withstand repeated sterilization cycles, and machined to exceptionally tight tolerances to ensure flawless, life-critical movements.

Material:

316L Stainless Steel

Finishing:

Electropolishing for a smooth, sterile surface

Key Tolerance:

Internal Bore Position: ±0.003 mm

Machining Process:

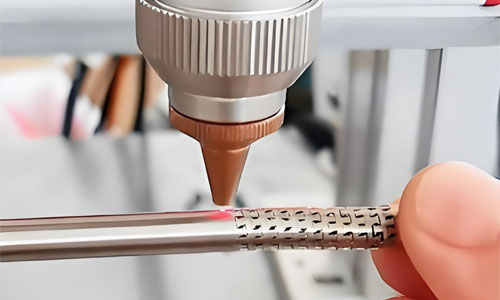

Swiss-Style CNC Turning & 5-Axis Milling

Outcome: By utilizing our climate-controlled quality lab and CMM inspection, we delivered parts with 100% dimensional accuracy. The electropolished 316L stainless steel parts easily passed the client’s rigorous biocompatibility and sterilization tests.

Case Study 3: EV Transmission Reduction Gear

For a Tier 1 automotive EV powertrain supplier.

The client needed a high-strength reduction gear for a new EV transmission. The part required superior wear resistance to handle high torque loads and an exceptionally fine surface finish on the gear teeth to minimize powertrain noise and maximize efficiency.

Material:

4340 Alloy Steel

Finishing:

Case Hardening & Isotropic Superfinishing

Key Tolerance:

Gear Tooth Profile (AGMA Q14): ±0.002 mm

Machining Process:

CNC Turning, Gear Hobbing & Grinding

Outcome: Our integrated process, combining CNC turning with specialized gear grinding, achieved a tooth profile precision that reduced operational noise by 15%. The superfinished surface decreased friction, contributing to a 2% increase in powertrain efficiency.

Want to learn more about CNC machining products? Visit our machining product showcase page to explore more and discover how our precision manufacturing solutions can meet your specific needs.

Our Capabilities

Advanced manufacturing and quality assurance facilities

State-of-the-art CNC milling, turning, and 5-axis machining centers

CMM, optical comparators, and advanced metrology equipment

In-house material analysis and mechanical testing capabilities

ISO 9001:2015 certified with strict quality control processes

Steel parts manufacturing Methods Comparison:

Machining Method | Features | Applications | Tolerances | Surface Finish | Cost |

CNC Turning | Ideal for cylindrical parts, high precision, efficient production | Mechanical parts, automotive components | ±0.01 mm | Smooth (Ra 0.8-1.6 µm) | Medium |

CNC Milling | Multi-axis machining for complex geometries | Aerospace, molds, mechanical components | ±0.01 mm | High quality (Ra 0.8-3.2 µm) | Medium |

3D Printing | Layer-by-layer manufacturing, suitable for prototypes and complex parts | Prototypes, complex geometries | ±0.01 mm | Adjustable, rough to smooth | Low to medium |

Rapid Prototyping | Quick production for testing and prototyping | Design iterations, test samples | ±0.01 mm | Variable | Low |

Sheet Metal Fabrication | Suitable for large, thin parts with bending and cutting | Enclosures, brackets, panels | ±0.5 mm | Variable | Low |

Casting | Mass production of complex shapes, suitable for durable parts | Engine housings, mechanical components | ±0.01 mm | Medium (Ra 6.3-12.5 µm) | Low |

Brief Explanation of Cost Comparison:

- CNC Turning and CNC Milling:

High precision, moderate cost, suitable for high-demand precision machining. - 3D Printing:

Ideal for small batch production and complex parts, low upfront cost but higher for mass production. - Rapid Prototyping:

Lowest cost, ideal for quickly validating design concepts and prototypes. - Sheet Metal Fabrication:

Good for large-sized or thin parts, lower cost, efficient for mass production. - Casting:

Best for large quantities and complex shapes, lowest per-unit cost, though initial tooling can be expensive.

- CNC Turning and CNC Milling:

This comparison helps you choose the most suitable machining method based on your project’s requirements and optimize your costs accordingly.

Materials

100+ materials can be freely selected to meet your customized processing needs!

Metals

Metallic materials are rugged and offer excellent strength and durability.

Plastics

Lightweight and flexible, used in a wide range of industries.

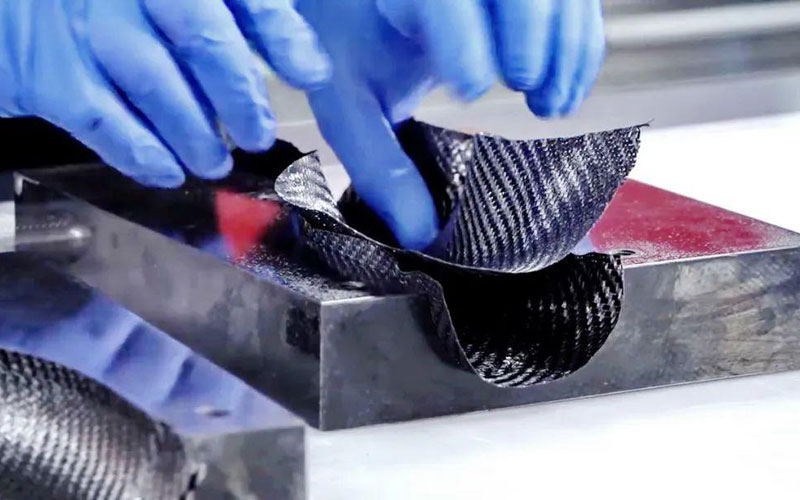

Composites

High-performance materials that combine strength and lightweight.

FAQ

Please provide us with the detailed design drawing or 3D model of the part, material requirement, quantity and delivery date. We will provide you with an accurate quote based on this information.

Yes, we support small-lot custom processing, which is suitable for prototype development or small-scale production needs.

Different types of steel (e.g. carbon steel, stainless steel, alloy steel) have different costs, and choosing higher performance or special specifications will increase the processing cost.

Steel is susceptible to rust by the environment, we can improve the corrosion resistance by surface treatment.

The lead time depends on the complexity of the part and the production lot, usually 7 to 30 working days, which will be provided upon confirmation of the order.

We use advanced CNC machining equipment to strictly follow the drawing requirements, and high precision testing equipment to ensure that the tolerance range of each part meets the standard.

Yes, we offer a wide range of surface treatment services, including plating, oxidizing, spraying and polishing, to help enhance the corrosion resistance, appearance and service life of the parts.

We can modify or re-process parts that have already been produced according to your requirements, and the exact cost of processing will depend on the scope of the modification.

Still have questions? Don’t worry — our CNC Machining FAQ page has more answers waiting for you. And if you need further help, our team is always ready to assist.

Ready to Start Your Steel Machining Project?

Upload your designs for a free quotation and DFM analysis