Optimizing Production for Custom Hydraulic Valve Blocks

How Allied Metal helped a European equipment manufacturer reduce unit costs by 30% through DFM analysis and smart tooling strategies.

- Heavy Machinery

- Aluminum 6061-T6

- 15 Days (Batch)

- -30% Cost

The Challenge

Our client, a mid-sized European brand specializing in hydraulic systems, designed a new generation valve block. The functionality was excellent, but the manufacturing economics were failing.

High Cost: The complex internal channels required 5-axis machining in a single setup, driving machine hourly rates too high.

Capacity Issues: Their local suppliers couldn’t handle the volume, and previous overseas attempts resulted in leakage issues due to poor tolerance control.

Our DFM Solution

Upon receiving the CAD files, Allied Metal’s engineering team didn’t just quote the part; we analyzed the manufacturability. We identified that 90% of the features could be done on a cheaper 3-axis or 4-axis machine.

Monolithic block requiring continuous 5-axis movement to reach undercut areas.

$$$ High Machining Cost

Proposed a split-design modification and custom fixture that allowed for 4-axis machining without compromising pressure rating.

√ 30% Cost Saving

Production & Results

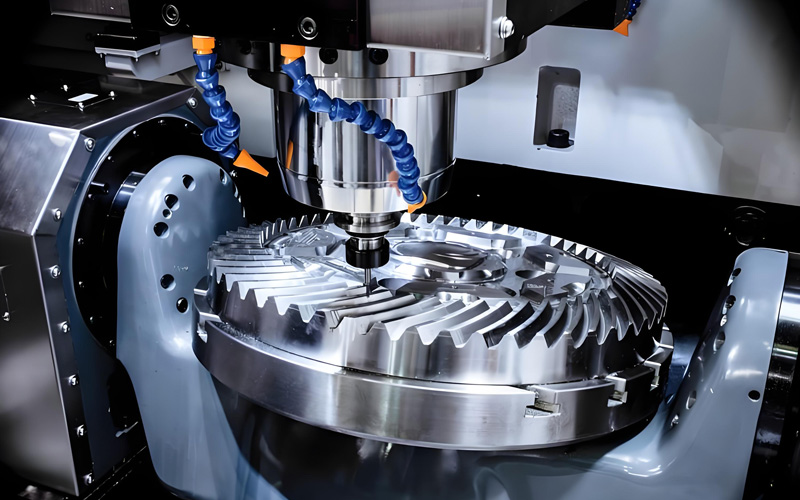

Once the design was approved, we moved to rapid production. We utilized our **Okuma 4-Axis Horizontal Machining Centers** for the main body to ensure perpendicularity and flatness.

Quality Assurance Data

Critical Dimension Tolerance: ±0.005mm (Pass)

Surface Roughness (Internal): Ra 0.8 (Pass)

Leakage Test: 100% Passed @ 300 Bar

Project Specs

Process

CNC Milling (4-Axis), Boring

Material

Aluminium 6061-T6

Surface Finish

Hard Anodizing (Type III) Black

Volume

500 units / batch

“Allied Metal’s engineering team saved us thousands of Euros on the first run alone. The parts fit perfectly.”

John D.

Product Manager, EuroHydraulics

Related searches

CNC Machining Services

Precision milling, turning, and drilling—from prototype to production.

Surface Finishing

Polishing, anodizing, plating, and more for enhanced durability and appearance.

CNC Materials Series

Aluminum, stainless steel, titanium, plastics—expert material selection.

Have a Complex Design?

Don’t let manufacturing costs kill your product launch. Let our engineers review your design for free and find the “Missing Link” to efficiency.