Table of Contents:

Surface Treatment Technology In CNC Machining

- January 14, 2025

- Tony

In CNC machining, surface treatment is an important part of improving the performance and appearance of parts. Through the use of different surface finish technology, parts can obtain higher wear resistance, corrosion resistance, strength and high-temperature resistance, to meet the more stringent application requirements.

1. Why surface treatment?

Surface preparation plays a vital role in CNC machining, mainly to enhance the functionality and appearance of parts. Many metals and alloys may face problems such as corrosion, wear and tear, and thermal expansion during manufacturing, and surface preparation can effectively address these issues. It can:

- Enhance performance: increase the wear resistance, corrosion resistance and hardness of the part so that it remains efficient in harsh environments.

- Improve appearance: By increasing surface gloss and color consistency, it enhances the visual effect of the parts and meets the appearance requirements of different industries.

- Extend service life: good surface finishes can prevent corrosion and wear, reduce equipment failure, extend the service life of parts and reduce maintenance costs.

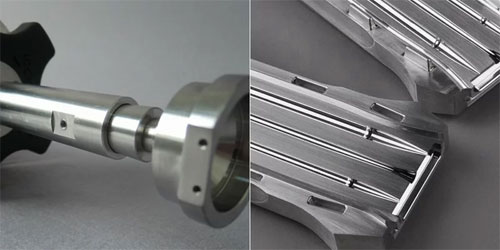

2. Common CNC Machining Surface Treatment Technologies

Anodizing

Anodic oxidation is to transform the metal surface into a layer of oxide film through an electrolytic reaction, which can enhance the corrosion resistance and hardness of the metal. Especially for aluminum alloys, anodizing not only provides protection but also increases its aesthetics for industries such as aerospace, automotive and electronics.

Electroplating

Electroplating is a technique in which metal ions are deposited on the surface of a part by passing an electric current through it. Common types of plating include nickel plating and chrome plating, which can significantly improve a part’s corrosion and wear resistance and aesthetics. Plating is widely used in automobiles, home appliances, and precision mechanical parts.

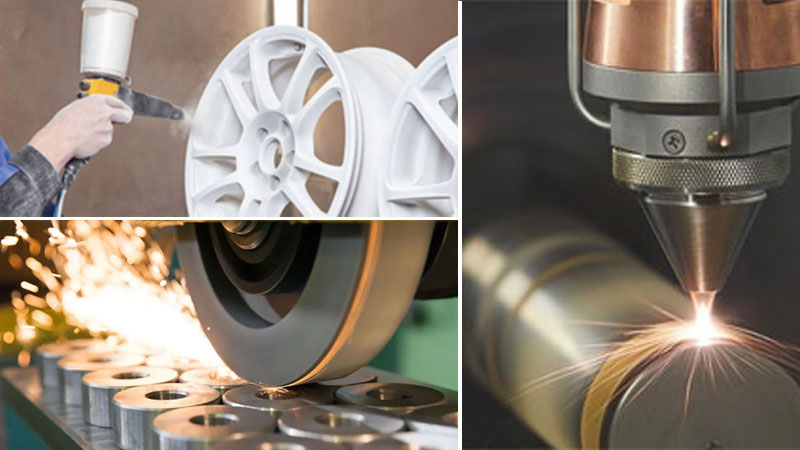

Spray Coating

Spraying technology includes powder spraying and liquid spraying, etc., which can provide a layer of uniform coating for the parts, and play a protective and decorative role. Spray coating not only improves the weather resistance of parts, but also enhances their corrosion resistance, and is widely used in the appliance, automotive and construction industries.

Laser Surface Treatment

Laser surface treatment technology uses a laser beam to irradiate a metal surface, rapidly heating and changing the surface microstructure to enhance its hardness and wear resistance. This technology is often used for surface finishing of precision components and can achieve very high precision and efficiency.

Heat Treatment

Heat treatment is a process that alters both the surface and internal structure of a metal through controlled heating and cooling.This method can dramatically increase the strength, hardness and high-temperature resistance of a part. Heat treatment is suitable for parts that are subjected to high loads and high-temperature environments.

Grinding

Grinding removes the rough layer on the surface of the part through mechanical grinding and polishing to achieve a smooth, even finish. Grinding not only improves the appearance of parts, but also reduces friction and wear, and is widely used in precision machinery and automotive parts.

3. How does surface treatment technology improve part?

Different surface treatment techniques can greatly enhance a part’s performance. Key areas of enhancement include:

- Wear resistance: Anodizing, laser surface treatment, etc. can reduce surface wear and prolong the service life of parts.

- Corrosion resistance: techniques such as plating and painting can effectively prevent oxidation and corrosion of metal surfaces, especially in harsh environments, providing additional protection.

- Reinforcement of strength and hardness: Heat treatment, laser surface finishes and other technologies can enhance the hardness and compression resistance of parts to ensure their stability in high-intensity environments.

- High-Temperature Resistance: For high-temperature working environments, surface finishes can improve the heat resistance of parts to avoid performance degradation caused by high temperatures.

4. How to Select the Right Surface Treatment Technology?

There are several factors to consider when selecting the right surface finishes:

The surface treatment technology is matched to the material:

Parts made of different materials require different surface treatments. For example, aluminum alloy is suitable for anodizing, while steel is suitable for plating or heat treatment.

Application requirements of the manufactured part:

Select surface finishes technology according to the use of parts and functional requirements, for example, high temperature, high-pressure environment of the parts need to be more resistant to high-temperature treatment technology.

Cost and efficiency of surface treatment:

Different surface finish technologies differ in cost and efficiency, and companies should make a reasonable choice based on budget and production requirements.

5. Practical Application Cases of Surface Treatment Technology

Automobile parts:

Automobile parts need to have high wear resistance and corrosion resistance. Surface treatment technologies such as electroplating, anodizing and spraying can significantly improve the durability and appearance of the parts to meet the high standards of the automotive industry.

Aerospace parts:

Aerospace parts operate in extreme environments and require high-temperature resistance and corrosion resistance. High-temperature coatings and corrosion-resistant surface treatments ensure stable operation in high-temperature, high-pressure environments.

Industrial machinery parts:

The surface finishes of industrial machinery parts are mainly concerned with improving hardness, wear resistance and surface finish. Commonly used techniques include grinding, laser surface treatment and heat treatment to enhance part performance and extend service life.

6. Surface treatment technology in environmental protection and sustainable development

As environmental regulations continue to strengthen, surface treatment technology is developing in a greener, more sustainable direction.

The application of environmentally friendly technologies, such as chromium-free plating and low-pollution spraying, meets the functional needs of parts while complying with strict environmental standards, providing strong support for the sustainable development of the industry.

Throughout this process, Allied Metal is committed to utilizing the latest environmental technologies to ensure that we provide our customers with efficient and environmentally friendly surface treatment solutions, while helping companies to comply with increasingly stringent environmental requirements.

7. Summary and Future Outlook

Surface treatment technology plays a vital role in CNC machining, and with continuous technological innovation, more efficient and environmentally friendly surface treatment methods may appear in the future. These new technologies will play a greater role in improving part performance, extending service life and reducing costs.