Table of Contents:

CNC Machining Essentials: Tolerance and Fit Guide

- November 21, 2024

- Tony

1. What is tolerance and fit?

Tolerance is the permissible range of deviation between the actual dimensions of a part and its design dimensions, which is used to ensure that the part can maintain a certain degree of accuracy during the manufacturing process without causing an increase in cost as a result of being too tight.

Fit refers to two parts in contact with each other after the assembly of the relative position of the relationship, which mainly includes clearance fit, transition fit and interference fit.

The two, tolerance and fit, are closely related and together determine the assembly performance and mechanical function of the part.

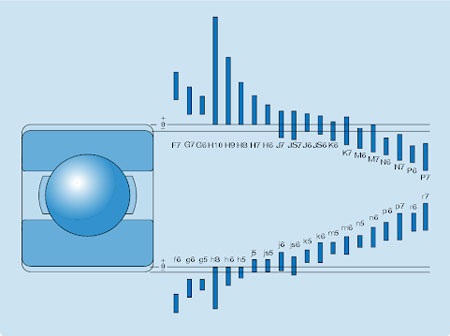

2. Basic classification and standard of tolerance

Tolerances are generally divided into the following categories:

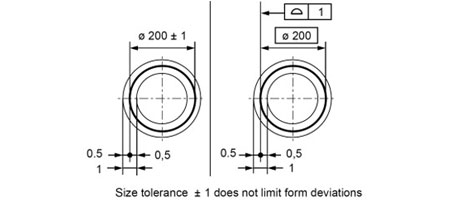

Dimensional Tolerances

Specify restrictions on a part’s basic measurements, including dimensions like length, width, and diameter.

Form&Position Tolerances

Control the allowable deviations in a part’s shape and alignment, such as parallelism or cylindricity.

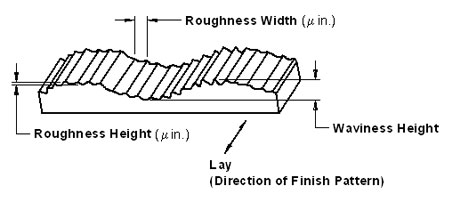

Surface Roughness

Indicates the smoothness level of a part’s surface, directly influencing its performance and quality.

Commonly used tolerance standards include the ISO and GB standards, and these specifications provide clear guidelines for tolerance labeling and design.

3. Types and applications of fits

According to the setting of tolerances, fits can be categorized as:

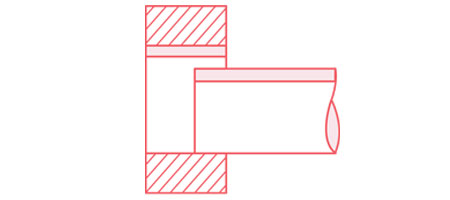

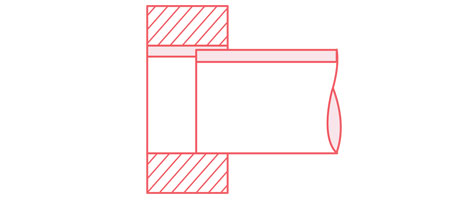

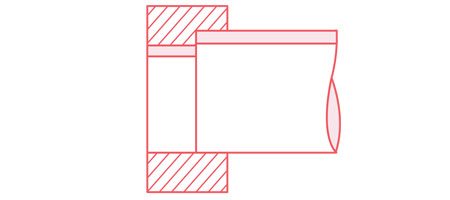

Clearance fit

A small gap remains after assembly, allowing free movement, commonly applied in sliding mechanisms.

Transition fit

Depending on tolerances, there may be a slight gap or interference, suitable for precise yet non-fixed components.

Interference fit

Parts are tightly joined with no gap after assembly, typically used for fixed mechanical structures.

These fits are widely used in bearings, gears, machine tools, etc. to ensure the reliability and performance of equipment.

4. Design Principles of Tolerance and Fit

Designing tolerances requires balancing accuracy and cost. While high-precision tolerances enhance performance, they also increase machining complexity and expenses.

To ensure proper functionality without unnecessary challenges, consider material properties, part functions, and assembly requirements when designing fits.

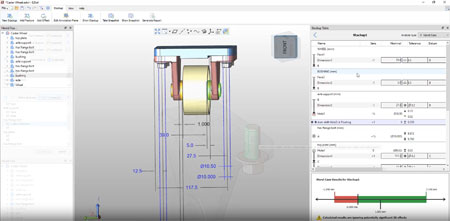

5. Application of tolerance and fit in CNC machining

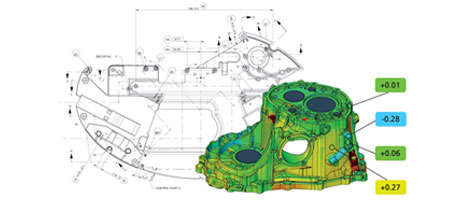

In CNC machining, tolerances and fits are key to precision and functionality.

Tolerances set allowable dimensional variations, balancing accuracy and cost. Tight tolerances improve precision but raise machining difficulty and expenses, while loose tolerances simplify production but may affect performance.

Fits define how parts interact after assembly, affecting movement and stability. Proper fits ensure functionality, while poor fits can cause assembly issues or failures.

By balancing tolerances and fits, CNC machining achieves high quality, reliable performance, and cost efficiency.

6. How to ensure machining accuracy and tolerance control?

To ensure machining accuracy and effective tolerance control, several key factors must be addressed:

1. High-Quality Equipment

Use advanced CNC machines with precise cutting capabilities to minimize dimensional deviations.

2. Tool Selection and Maintenance

Choose appropriate cutting tools and maintain them regularly to prevent wear that could impact accuracy.

3. Material Properties

Understand the material’s behavior during machining, such as thermal expansion, to adjust processes accordingly.

4. Process Optimization

Optimize machining parameters, including cutting speed, feed rate, and depth, to achieve consistent results.

5. Inspection and Measurement

Implement rigorous quality checks using tools like CMM (Coordinate Measuring Machines) to verify tolerance compliance.

7. Case study of tolerance and fit

Case Study: Tolerance and Fit in Aircraft Turbine Blades

In the aerospace industry, turbine blades must meet strict tolerances and fits to ensure optimal performance and safety under extreme conditions.

1. Tolerance in Turbine Blades:

- Dimensional Precision:

Blades must fit precisely into the turbine disk with minimal gaps to avoid air leakage, which can reduce efficiency. Typical tolerances for critical dimensions are within ±0.005 mm. - Surface Finish:

A high-quality finish, often around Ra 0.2–0.4 µm, minimizes drag and enhances airflow.

2. Fits in Turbine Assemblies:

- Interference Fit:

The root of the blade is often designed for an interference fit with the turbine disk. This ensures the blade remains firmly secured during operation despite high centrifugal forces and vibrations. - Thermal Expansion Consideration:

Materials are chosen to account for thermal expansion differences between the blade and disk to prevent stress buildup.

3. Challenges and Solutions:

- Challenge:

Maintaining tight tolerances during machining due to blade complexity and material hardness (e.g., titanium or nickel-based alloys). - Solution:

Employing 5-axis CNC machining for precise contouring and using specialized tools with robust coatings to handle hard materials.

8. Summary and Outlook

Tolerance and fit are the core elements of precision machining, which directly affect the performance, assembly quality and manufacturing cost of parts.

In the future, with the advancement of CNC technology and automation level, tolerance control will become more efficient and precise, bringing broader development prospects for more industries.