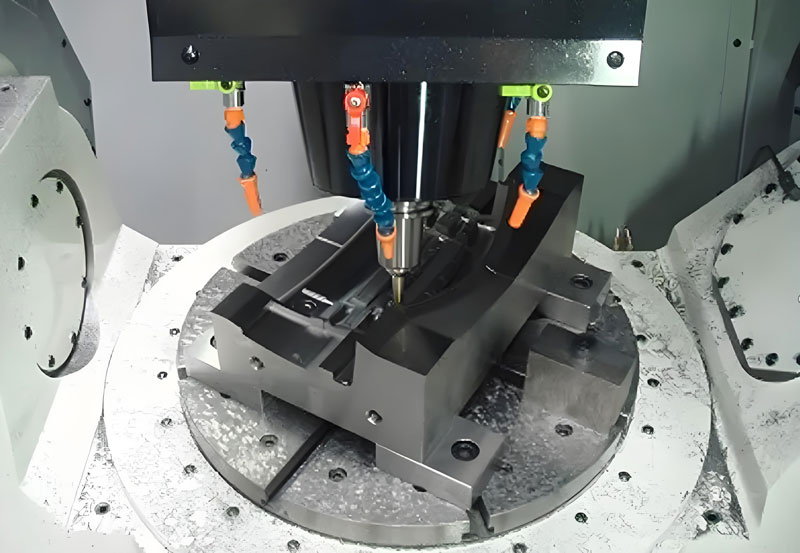

5-axis CNC machining is an advanced mode of CNC machine tool machining that allows the tool to approach the workpiece from virtually any angle, making it ideally suited for machining complex three-dimensional shapes such as turbine blades and molds.

5-axis CNC machining offers higher machining accuracy and wider applicability than 3- and 4-axis machining, especially in machining tasks that require 5-axis CNC machining offers higher precision and wider applicability than 3- and 4-axis machining, especially in machining tasks that require high precision and complex shapes.