Machining hard materials is tough and costly. Traditional grinding processes are slow and require multiple steps, hurting your bottom line. Hard turning offers a faster, single-setup solution for you.

Hard turning is a CNC machining process used on materials with a hardness greater than 45 HRC. It uses specialized cutting tools to machine hardened steel, often replacing grinding. It combines roughing and finishing into a single setup, saving time and money.

I've seen firsthand how hard turning can revolutionize a production line. It's a game-changer, but many engineers still have questions about how it works and when to use it. Let's break down the details so you can see if it's right for your projects.

What is hard turning in manufacturing?

Many shops assume hardened materials must be ground. But that’s not always true. Hard turning works as a better alternative if done right.

Hard turning is a process that uses rigid CNC lathes and special cutting tools to machine parts made of hardened steel or other tough materials. It combines speed and accuracy in one setup.

Key Features of Hard Turning

To better understand this process, let’s break it down.

What Is the Material Range?

Hard turning is ideal for materials above 45 HRC. This includes:

- Tool steels (like D2, A2, M2)

- Hardened carbon steels

- Bearing steels

- Superalloys

Traditional turning would struggle with these. But when properly equipped, a hard turning setup can machine them cleanly and repeatably.

What Tools Are Needed?

You need high-quality polycrystalline cubic boron nitride (PCBN) inserts1 or ceramics. These hold up against the heat and wear during the cut. Carbide tools will typically fail early under these loads.

Also, the machine needs to be rigid. I’ve seen success only when we use machines with box ways or heavy-duty linear guides, minimal backlash, and good spindle bearing support.

What Are the Typical Tolerances?

With the right setup, hard turning can hit tolerances of ±0.001 mm and surface finishes around Ra 0.2 to 0.4 µm—comparable to fine grinding in many cases.

What is the difference between hard turning and soft turning?

You understand CNC turning, but the terms "soft" and "hard" can be confusing. Choosing the wrong one can mess up your production plan. The key difference is the workpiece's hardness.

Soft turning machines parts before heat treatment, when the material is in a softer state (under 45 HRC). Hard turning machines parts after they have been heat-treated and hardened. Soft turning removes bulk material, while hard turning focuses on final precision and finish.

The biggest difference between soft and hard turning is the timing in the manufacturing sequence. It determines everything from the tools we use to the final result. Soft turning is the initial step. We take a raw piece of metal and machine it to near-net shape while it's still relatively easy to cut. After soft turning, the part goes for heat treatment to achieve the desired hardness and strength. Then, if needed, it comes back for a final finishing operation. This final step is where hard turning comes in. It corrects any distortions that happened during heat treatment and brings the part to its final, precise dimensions.

Here’s a simple breakdown:

| Feature | Soft Turning | Hard Turning |

|---|---|---|

| When It's Done | Before heat treatment | After heat treatment |

| Material Hardness | Below 45 HRC | Above 45 HRC |

| Main Goal | Bulk material removal, shaping | High precision, fine surface finish |

| Cutting Tools | Standard Carbide | CBN, Ceramics |

| Depth of Cut | Large | Small, fine cuts |

| Process Type | Roughing / Semi-Finishing | Finishing |

You wouldn't use hard turning for roughing because it's slower and the tools are more expensive. It's a specialized finishing process designed for ultimate accuracy on hard parts.

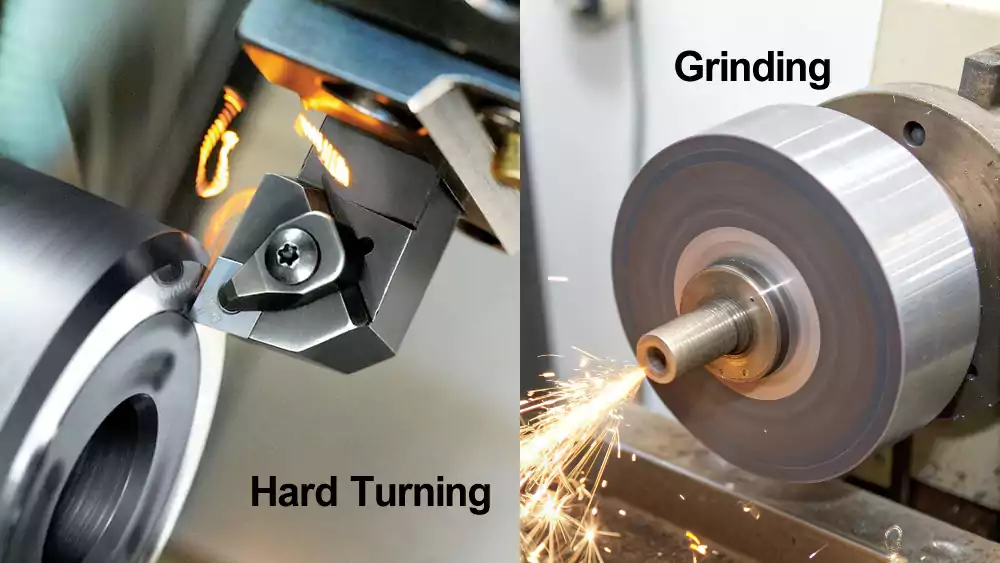

What is the difference between grinding and hard turning?

Both processes finish hardened parts, so it's hard to know which to choose. Picking the less optimal method can cost you time and money. Let's compare them directly.

Hard turning is a cutting process using a defined cutting edge (like a lathe tool). Grinding is an abrasive process using a wheel with many undefined cutting edges. Hard turning is often faster, more flexible, and can consolidate operations into a single machine setup.

For many years, grinding was the gold standard for finishing hardened components. It's incredibly precise. However, hard turning has emerged as a strong competitor, and in many cases, a better option. The fundamental difference is how they remove material. Think of hard turning as using a very sharp, very tough scalpel to slice away material. Grinding is more like using high-speed sandpaper. Both can achieve a great result, but the path to get there is different. I remember working on a project for hydraulic piston rods. The specs required a very fine finish on hardened steel. We initially quoted it using grinding, which involved two separate setups. By re-evaluating the process and using hard turning, we did the entire job on one CNC lathe. We reduced the cycle time by nearly 40% and passed those savings on to the client.

Here’s a comparison:

| Feature | Hard Turning | Grinding |

|---|---|---|

| Process | Single-point cutting (shearing)2 | Multi-point abrasive (plowing/rubbing)3 |

| Flexibility | High (can do contours, tapers easily) | Lower (wheel shape limits geometry) |

| Setup Time | Shorter (often one setup) | Longer (may require multiple machines) |

| Cycle Time | Generally faster | Generally slower |

| Coolant | Can often be done dry | Usually requires large amounts of coolant |

| Environmental | Better (dry cutting, recyclable chips) | More complex (coolant/sludge disposal) |

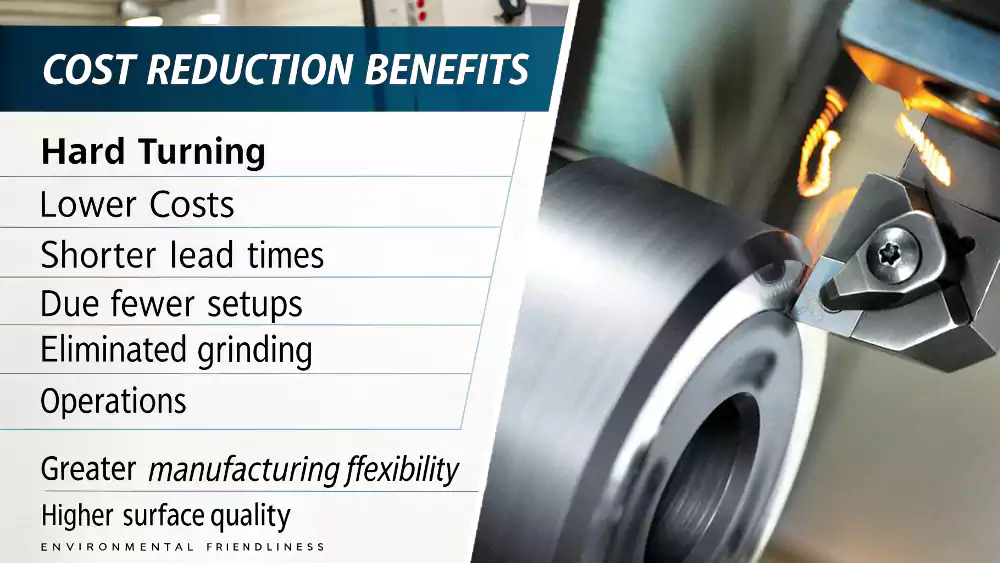

What are the advantages of hard turning?

You're always looking for ways to improve efficiency. Sticking with older, slower methods can hurt your competitiveness. Hard turning offers some major advantages you should know about.

The key advantages are lower costs and shorter lead times. This comes from reducing setups and eliminating separate grinding operations. It also offers greater manufacturing flexibility, improved surface quality, and is often more environmentally friendly than grinding due to reduced coolant usage.

When I talk to engineers like David, the benefits of hard turning really get their attention. It’s not just a minor improvement; it can fundamentally change the economics of producing a part. The advantages stack up quickly, making it a powerful tool in modern manufacturing.

Reduced Costs and Lead Times

This is the biggest win. By combining operations that would normally require a lathe and a grinder into one machine, you eliminate setup time, part handling, and work-in-progress inventory. Fewer machines mean less capital investment and lower energy consumption. I've seen projects where hard turning cut total machining time and cost by 30-70% compared to a traditional turn-and-grind process.

Enhanced Flexibility and Quality

A single CNC lathe can perform turning, facing, grooving, and boring on a hardened part in one go. This is a level of flexibility that grinding can't match. Grinding often requires specialized machines for different features. Hard turning also produces a superior surface structure. It creates compressive residual stresses, which can improve the fatigue life of the component. It's a small detail that makes a big difference in high-performance applications.

What are the key factors to consider when implementing hard turning in a manufacturing process?

You're ready to try hard turning but are unsure of the requirements. Rushing in can lead to costly mistakes and damaged parts. Success depends on a few critical factors.

Success hinges on four main things: a highly rigid and stable machine tool, the correct cutting tool material (usually CBN), secure work holding, and carefully optimized cutting parameters. The material's specific hardness and consistency are also crucial to the outcome.

Implementing hard turning isn't as simple as just buying CBN inserts. It's a complete system where every component has to be right. Getting one part wrong can compromise the entire process. As a shop owner, I focus on these areas to guarantee success for my clients' projects.

1. The Machine Tool

Rigidity is everything. The machine base, spindle, and turret must be incredibly stiff to absorb cutting forces without vibrating. Any chatter will be transferred directly to the part's surface. High-precision guideways and a powerful spindle are essential.

2. The Cutting Tool and Holder

You need the right tool for the job. This usually means PCBN inserts4, but the specific grade and edge preparation depend on whether the cut is continuous or interrupted. The tool holder must also be robust to minimize overhang and provide a secure clamp on the insert.

3. The Workpiece

The material must be suitable for hard turning. This means consistent hardness throughout the part. Inconsistent hardness can lead to unpredictable tool wear and poor surface finish. The way the part is held in the machine (the chuck and jaws) is also critical for stability.

4. Cutting Parameters

Finally, the programming—the speeds, feeds, and depth of cut—must be just right. This is where experience comes in. We typically use high cutting speeds but low feed rates and shallow depths of cut to achieve a great finish without overloading the tool.

What are the common applications for hard turning?

You understand the theory of hard turning, but where does it apply? Without knowing its common uses, you might overlook a chance to improve one of your own parts.

Hard turning is widely used in industries requiring high-precision, wear-resistant parts. Common applications include automotive transmission gears, bearing races, hydraulic components, camshafts, and axles. It is ideal for finishing parts made from hardened steel and other tough alloys.

Hard turning isn't a niche process; it's a mainstream solution for many high-stakes industries. When a part needs to be both hard and precise, hard turning is often the best cdhoice. For an engineer like David working in industrial automation, this is highly relevant.

Automotive Industry

This is one of the biggest users. Think about all the moving parts in a car's transmission and engine. We use hard turning to finish transmission shafts, gear faces, and clutch components. These parts must withstand incredible stress and wear, and hard turning delivers the necessary precision and surface integrity.

Bearing Manufacturing

The inner and outer races of ball and roller bearings are classic examples. They are made from extremely hard steel and require a flawless surface finish for smooth operation and long life. Hard turning is often used to finish these races after heat treatment.

Hydraulics and Industrial Machinery

In David's field, components like hydraulic cylinder rods, valve spools, and pump shafts must be hard and straight to prevent leaks and wear. Hard turning is perfect for achieving the tight tolerances and fine finishes needed for these seals to work correctly. It's a faster, more flexible alternative to grinding for many of these parts.

How can you ensure success with your hard turning project?

Finding a manufacturing partner for a specialized process like hard turning is a challenge. The wrong choice can lead to delays and bad parts. You need a shop with proven expertise.

To ensure success, partner with a shop that has invested in the right technology and expertise. At Allied Metal, we combine rigid CNC machines, advanced CBN tooling, and years of hands-on experience to deliver precise, cost-effective hard-turned components for your critical applications.

Why Works With Us?

We don’t just offer hard turning—we’ve made it part of our workflow. Our customers come to us because:

- We offer fast quotes based on your drawings

- We keep tolerances tight, even on complex materials

- We protect your design data with strict confidentiality

- We’ve shortened production lead times without cutting corners

Whether it’s a prototype or a production run, our team has the tools and experience to deliver precision parts, fast.

Conclusion

In short, hard turning is a highly efficient process for finishing hardened parts. It reduces costs and lead times compared to grinding, making it a smart choice for modern manufacturing.

-

Explore this link to understand the benefits and applications of PCBN inserts in machining, enhancing your tool selection. ↩

-

Understanding single-point cutting shearing can enhance your knowledge of machining processes and their applications. ↩

-

Exploring multi-point abrasive machining will provide insights into its advantages and applications in manufacturing. ↩

-

Explore this link to understand how PCBN inserts enhance cutting performance and tool life in hard turning applications. ↩