There are many types of precision machining, here are 5 common types of precision machining and applicable materials:

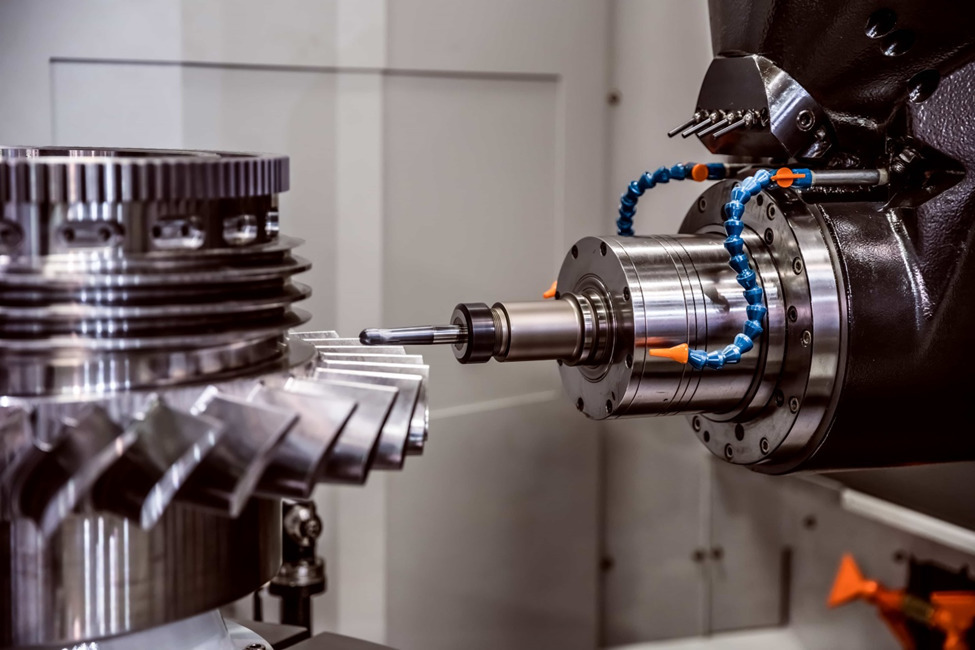

Ultra-Precision Turning

Ultra-precision turning is the use of high-precision lathes and specially designed tools for fine machining of workpieces.

The core principle is to achieve extremely high machining accuracy and surface quality through precise control of the tool’s trajectory and cutting parameters.

Commonly processed materials for precision turning include: metals, plastics, ceramics and high-performance materials for specific industrial applications.

Because of its high stability, high precision and wide material adaptation, it is widely used in optical devices, semiconductor industry, aerospace, etc., such as optical lens manufacturing, high-precision bearings and gyroscope parts.

Electrical Discharge Machining (EDM)

Electrical Discharge Machining(EDM) is a high-precision machining technology that utilizes electric spark discharge to etch materials.

Especially suitable for processing high hardness, complex shape and high precision requirements of conductive materials.

Commonly processed materials include: metal, silicon carbide, graphite and so on.

Due to the high hardness and high precision, it is widely used in the fields of mold manufacturing, electronics industry, medical devices, such as turbine blade processing, injection molding and stamping molds, and microporous manufacturing.

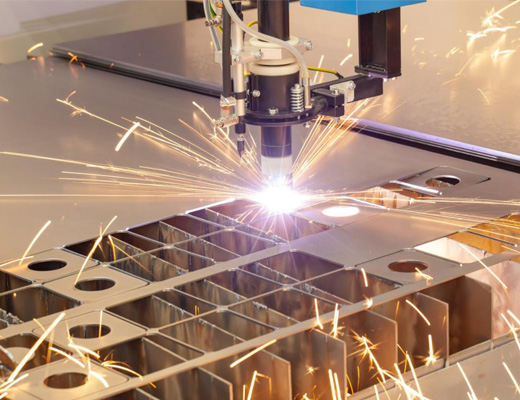

Laser Machining

Laser processing is the use of focused high-energy laser beams on the material for local irradiation, resulting in high temperatures, so that the material melts, vaporizes or causes physical and chemical changes, so as to achieve the purpose of cutting, welding, punching and so on.

Commonly used types of lasers include: CO2 lasers, fiber lasers, solid-state lasers and ultraviolet lasers.

Commonly processed materials for laser processing include: metals, plastics, wood, ceramics and so on.

Because of its high precision, diversity, high efficiency and other characteristics, it can be widely metal cutting, electronic component manufacturing, medical equipment and other fields.

Micro electroplating

Microfine plating is the deposition of a thin layer of metal on the surface of a workpiece by electrochemical reaction.

The workpiece acts as a cathode and is immersed in an electrolyte containing metal ions. Under the action of an applied electric field, the metal ions are reduced on the surface of the workpiece, resulting in the formation of a uniform metal coating.

Microplating

Common plating materials include: gold, copper, platinum, and silver.

Because of its high precision and high adhesion, it can be widely used in the electronics industry, microelectromechanical systems, medical devices, precision engineering and other fields.

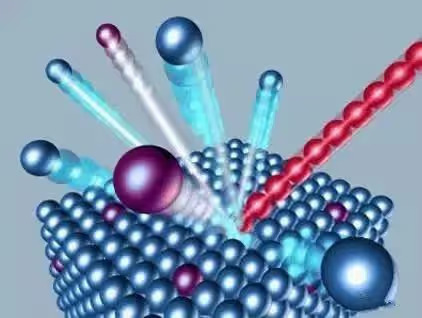

Focused Ion Beam(FIB)

This technology utilizes a highly focused ion beam to perform fine nanoscale processing of materials, demonstrating unparalleled precision and versatility.

Focused Ion Beam Processing is the use of high-energy ion beams, which are focused to a nanometer diameter under the action of electric and magnetic fields and bombard the surface of the workpiece by scanning or fixed-point bombardment to cause sputtering, deposition, or modification of the material. The main modes of operation include etching and deposition.

Commonly processed materials include ceramics, metals, quartz, polymerized materials and so on.

Due to its advantages of high precision and flexibility, it is widely used in: semiconductor manufacturing, electron microscope sampling, material science and other fields, such as nanohole preparation, high-resolution cross-section analysis, integrated circuit repair and so on.

Precision Machining Service Provider in China

Allied Metal is one of the leading suppliers of precision machining service in China. We have our own factory, with the company’s strong R&D and technical strength, after years of reliable operation and perfect after-sales service, we have gained a lot of praise from customers.

When you have precision machining needs, please send us an email, we will make the most suitable machining program for you according to your actual needs and product standards to be achieved.