Last updated October 22, 2025 by Lucy

Basic Overview

What is Carbon Fiber?

Carbon fiber is a high-strength material made from carbon atoms through a special manufacturing process. It is an ideal material for lightweight, high-strength applications and is a key material for future high-tech industries.

Basic Manufacturing Processes of Carbon Fiber

The manufacturing process usually includes the steps of pre-oxidation, carbonization and post-treatment.

First, by heating polyacrylonitrile (PAN) or other raw material fibers to a high temperature, they undergo a chemical reaction to form a long chain structure with carbon atoms arranged. After high-temperature carbonization, high-strength carbon fibers are eventually formed.

Different manufacturing processes determine the different characteristics, which in turn affects their performance in various applications.

Main Properties of Carbon Fiber

- Lightweight and High Strength: It is extremely lightweight yet stronger than steel.

- Low Density: With a much lower density than metals, it’s ideal for applications where weight is crucial.

- Heat and Corrosion Resistance: It performs well in high-temperature environments and is highly resistant to corrosion.

- Wide Applications: These qualities make it essential in industries like aerospace and automotive, where strength and low weight are paramount.

Types of Carbon Fiber

Classification according to carbon content

High Strength Carbon Fibers (HS)

HS is the most common category and is mainly used in applications that require higher strength. It has high strength but relatively low modulus and is used in aerospace, automotive and sports equipment.

High Modulus Carbon Fibers (HM)

HM has higher stiffness and provides greater resistance to deformation. It is commonly used in high-performance engineering structures such as critical components in aerospace.

Ultra High Strength Carbon Fibers (UHS)

UHS, on the other hand, mainly emphasizes extreme strength and is suitable for applications in extreme conditions requiring ultra-high strength and low weight, such as the military and special industries.

Classification according to production process

Pre-oxidized Fiber

Pre-oxidized fibers are raw fibers used in the manufacturing process, which are usually transformed into oxidized materials through heat treatment to prepare for the subsequent carbonization process.

Polyacrylonitrile (PAN)

Polyacrylonitrile (PAN)-based carbon fibers are the most common type available, widely used in aerospace and automotive industries for their excellent formability and high strength.

Silicon Carbide-based Carbon Fibers (C/SiC)

C/SiC use a special production process that gives them higher heat and oxidation resistance, and are typically used in high-temperature environments for applications such as engine components.

Classification according to fiber morphology

Monofilament Carbon Fiber

It is the basic form, primarily used for high-strength applications, especially in composites where they are crucial for performance.

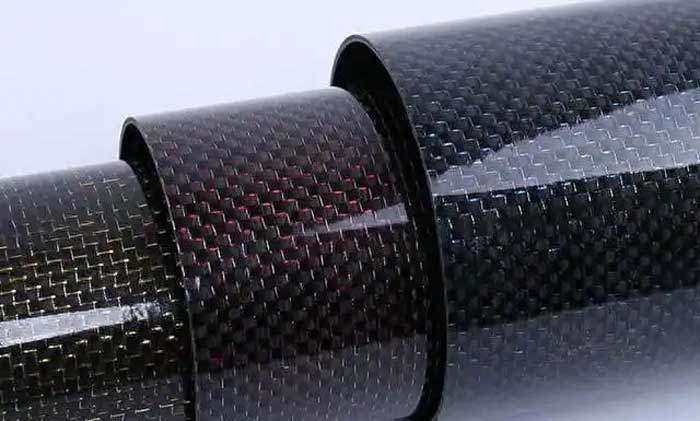

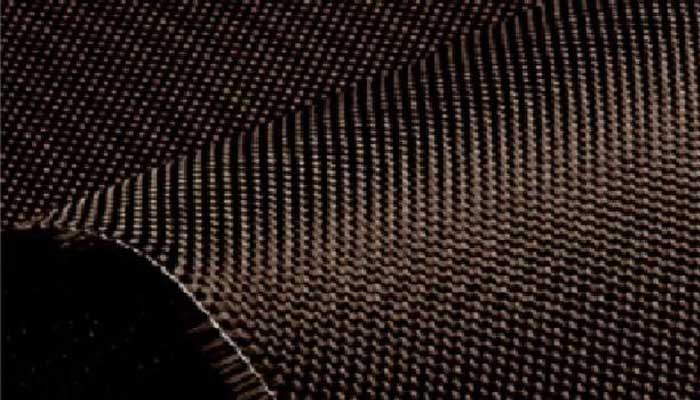

Polymer-based composites

Composites like carbon cloth and carbon paper consist of multiple monofilament strands woven together and are commonly used to mold intricate shapes and structures.

Classification according to mechanical properties

High Strength Carbon Fibers

High-strength carbon fibers emphasize the tensile strength of the fibers and are suitable for applications that require a high degree of durability when subjected to external forces.

High Modulus Carbon Fibers

The advantage of this type of material is its resistance to deformation, making it ideal for use in structures that require a high degree of rigidity.

Composite carbon fibers

It combines the advantages of high strength and high modulus and is suitable for use in complex environments and extreme conditions.

Carbon Fiber Applications in Industry

Aerospace

Carbon fiber is widely used in aerospace, mainly in the manufacture of aircraft fuselage and wing structures.

Due to its excellent strength-to-weight ratio, it can effectively reduce the weight of aircraft and improve fuel efficiency.

Automotive

In the automotive industry, this material is used in the body, components, and other lightweight designs.

High-performance racing cars and electric vehicles use carbon fiber in large quantities to reduce overall vehicle weight and improve performance and range.

Motorcycle Industry

The motorcycle industry is also actively using carbon fiber to manufacture frames and components.

This new composite material customizes motorcycle parts to make the body lighter and stronger, improving acceleration and handling, especially for high-performance models and racing cars.

Sports Equipment

Carbon fiber is particularly widely used in sports equipment, especially in golf clubs, badminton rackets, and bicycle frames.

Its high strength and lightweight properties enable athletes to maneuver more easily and improve competitive performance.

Case Study: Carbon Fiber in Aerospace Wing Components

Project Overview: A leading aircraft manufacturer replaced traditional aluminum alloy with carbon fiber composites for the primary wing components of their new-generation narrow-body aircraft. The transition aimed to reduce overall weight while maintaining structural integrity under extreme flight conditions.

Performance Parameters & Results:

- Component Specification: Main wing box structure including spars and ribs

- Material Composition: T800-grade carbon fiber with epoxy resin matrix

- Weight Reduction: Achieved 35% reduction compared to conventional aluminum design, bringing component weight down to 280 pounds (127 kg)

- Mechanical Properties: Tensile strength rated at 5,800 MPa with a stiffness modulus of 290 GPa

- Thermal Performance: Maintains dimensional stability across temperature extremes from -67°F to 302°F (-55°C to 150°C)

- Fatigue Resistance: Withstands over 100 million load cycles without significant degradation

- Operational Impact: Contributes to 12% improvement in fuel efficiency and annual CO₂ reduction of approximately 25 tons per aircraft

The successful implementation demonstrates carbon fiber’s capability to meet rigorous aerospace standards while delivering substantial economic and environmental advantages. This application paves the way for broader adoption in next-generation aircraft designs.

How to ensure the machining accuracy of the axes?

It is widely utilized in the new energy sector due to its lightweight nature, strength, and long-lasting durability.

- In wind energy, it enhances the efficiency and lifespan of turbine blades.

- In electric vehicles, it reduces weight, improving battery performance and range.

- Additionally, it plays a key role in energy storage systems, boosting performance and durability.

Future Trends in Carbon Fiber Applications

As manufacturing processes evolve and production costs decrease, carbon fiber applications are expanding into renewable energy, infrastructure, and consumer electronics. Sustainable production methods and recycling technologies are also advancing to address environmental concerns.

Summary

Carbon fiber has become one of the indispensable materials in the modern manufacturing industry with its excellent performance and wide application prospects.

With the continuous development of technology and the expansion of application fields, it will play a greater role in more industries and promote the progress and innovation of industrial technology.