Editor’s Note: Updated 2025-10-16 17:05:54 Thursday

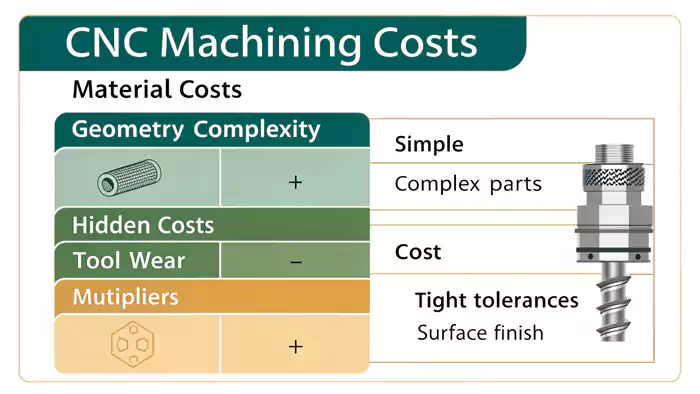

Wondering why your CNC machining quote varies wildly? Prices hinge on three pillars: materials, design complexity, and machine time. Let me decode the real costs behind precision machining.

Custom CNC machining costs range from $65 to $300+ per part, varying with material ($20–$150/kg), geometry (10–20+ hours of machining), and order volume (20–50% savings for bulk).

Stick around—I’ll show you how to slash machining expenses without compromising quality, using strategies we’ve refined over 500+ projects at Allied Metal.

How to estimate CNC machining cost?

Estimation errors can burn budgets fast. Miss one variable and your quote skyrockets.

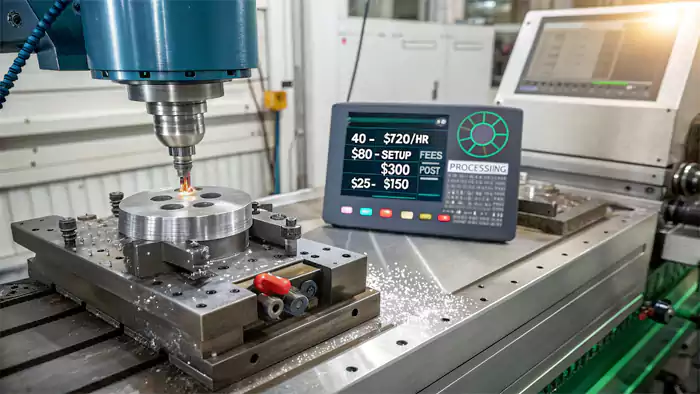

Estimate CNC costs by calculating material volume, machine time ($40–$120/hr), setup fees ($80–$300), and post-processing ($25–$150). Use CAD software with machining time plugins for accuracy.

Key Estimation Variables

| Factor | Impact Range | Calculation Method |

|---|---|---|

| Material Cost | 15–60% total | (Part Volume × Material Density × $/kg) + 10% Waste |

| Machine Time | 20–45% total | CAM Software Output + 15% Buffer Time |

| Labor | 10–25% total | (Setup Hours × $65/hr) + (Runtime × $30/hr) |

| Surface Finish | $5–$75/part | Polishing: +$25, Anodizing: +$45, Painting: +$65 |

Our team benchmarks quotes using a 4-step checklist:

- Simplify undercuts in CAD (cuts 15–30% machining time)

- Compare stock material sizes to minimize waste

- Group small batches (5–10 parts) under one setup

- Opt for machinable alloys1 like 6061 aluminum first

Factors affecting the cost of CNC machining

Seen two quotes with 50% price gaps? Here’s why.

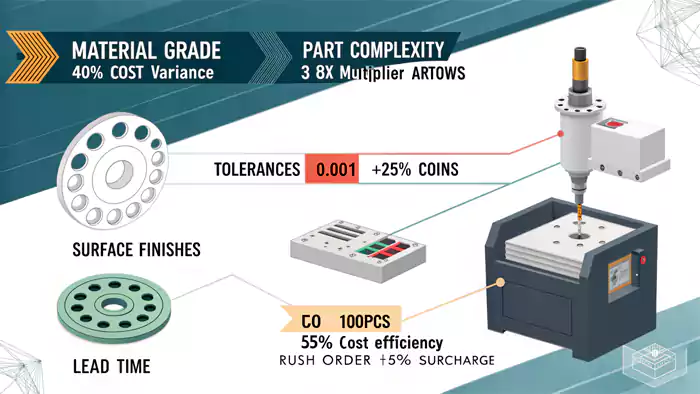

Top 6 CNC cost drivers: material grade (40% variance), part complexity (3–8X cost multipliers), tolerances (±0.001” = +25% cost), surface finishes (+$30–$200), order quantity (50–100+ cuts 35%), and lead time (rush jobs +50%).

Cost Optimization Matrix

| Cost Factor | Low-Cost Option | High-Cost Scenario | Savings Tips |

|---|---|---|---|

| Material | 6061 Aluminum ($3/kg) | Titanium Grade 5 ($50/kg) | Use steel where possible |

| Tolerances | ±0.005” | ±0.0005” | Loosen non-critical dimensions |

| Wall Thickness | 0.08” (no deflection) | 0.03” (requires supports) | Follow DFM guidelines |

| Surface Finish | As-machined (+$0) | Mirror Polish (+$85) | Specify only functional areas |

Critical point: A 0.5” radius instead of sharp corners reduces tool changes from 8 to 2—slashing 45 minutes off cycle times.

📘 Case Study: Custom Aluminum Bracket — Real CNC Machining Cost Breakdown

A production manager was tasked with producing a batch of precision aluminum mounting brackets for an automation fixture. The design involved multiple angled surfaces, fine tolerances, and an anodized finish—challenging for both budget and cycle time.

Project Parameters

| Specification | Details |

|---|---|

| Material | 6061-T6 Aluminum |

| Part Dimensions | 160 × 95 × 25 mm |

| Tolerances | ±0.02 mm (holes), ±0.05 mm (overall) |

| Surface Finish | Type II Clear Anodizing (Ra 1.2 µm) |

| Batch Size | 25 pieces |

| Machine Type | 3-axis CNC milling center (15,000 rpm spindle) |

| Cycle Time per Part | 28 minutes |

| Tooling Setup | Ø8 mm carbide end mill (TiAlN-coated), 2 roughing + 1 finishing pass |

Cost Breakdown (Per Part)

| Cost Component | Value | Notes |

|---|---|---|

| Raw Material | $9.80 | 6061-T6 aluminum billet |

| Machine Time | $56.00 | 0.47 hr × $120/hr |

| Setup & Fixturing | $18.50 | Distributed across batch |

| Tool Wear & Coolant | $5.20 | Carbide tool + coolant use |

| Anodizing & Post-Finish | $28.00 | Clear anodizing, Ra 1.2 µm |

| Quality Inspection | $6.50 | CMM dimensional verification |

| → Total Cost per Part | ≈ $124.00 | — |

Optimization and Results

In the first prototype run, excessive tool changes and dwell time extended the cycle to 36 minutes per part. After modifying the CAD model—adding 1.5 mm corner radii and standardizing hole diameters—the AI-assisted CAM tool reduced tool changes from 6 to 3.

Improvements achieved:

- Cycle time reduced: 36 → 28 minutes

- Cost per part reduced: –23%

- Dimensional accuracy improved: ±0.018 mm average deviation (CMM)

The production manager explained:

“Our biggest savings didn’t come from cheaper stock—it came from intelligent design changes. Once we optimized the geometry, the machine time dropped naturally.”

This example highlights how professional CNC machining services combine process expertise, DFM insight, and precision control to achieve both accuracy and efficiency. Whether it’s a single prototype or a short-run batch, the key to cost-effective CNC work lies in understanding how every design choice affects spindle time, tooling, and finish quality.

Ready to take your next project further?

Why is CNC machining expensive?

“Why does this tiny part cost $500?” Clients ask this weekly.

CNC machining costs stem from $150K–$500K machines, $65/hr skilled labor, $15K tooling budgets, and ±0.001” tolerances requiring climate-controlled shops. 60% of costs are fixed overhead.

Hidden Cost Breakdown (%)

| Category | Prototype (1–10pcs) | Production (100+pcs) |

|---|---|---|

| Machine Setup | 25% | 8% |

| Material | 20% | 35% |

| Labor | 30% | 20% |

| Tool Wear | 15% | 25% |

| Quality Control | 10% | 12% |

Three cost-reduction levers we use:

- Batching: Combining 5 jobs on one aluminum plate saves 3 setup hours ($195)

- Tool Life Extension2: Using carbide end mills lasts 10X longer than HSS

- Smart Tolerancing3: ±0.003” instead of ±0.001” cuts finishing passes by 75%

How to obtain low-cost CNC machined parts

Watching budgets bleed? Let’s fix that.

Cut CNC costs by 30–60% through design simplification (radial uniformity), bulk orders (50+ parts), and avoiding non-standard materials. DFM analysis often reveals 40%+ savings.

Cost-Saving Checklist

✅ Replace deep cavities with sliding fits (saves 3+ hours)

✅ Use stock tube/rod sizes (avoids $80+ custom stock fees)

✅ Limit thread lengths to 3× diameter (reduces tapping time)

✅ Cluster small features on one side (cuts 4-axis work)

At Allied Metal, our automated quoting system cross-references your design against 3,000+ past projects—often finding 15–25% savings via:

- Equivalent material substitutions4

- Optimal cutting parameter libraries

- Multi-part nesting simulations

Conclusion

CNC machining costs hinge on smart design choices, material tradeoffs, and batch optimization. Master these levers, and you’ll slash expenses while keeping precision. Ready to refine your approach?

-

Learn about the top machinable alloys that can improve your production quality and efficiency, ensuring optimal performance in machining. ↩

-

Understanding tool life extension can help you discover ways to enhance productivity and reduce expenses in your machining operations. ↩

-

This link will explain how smart tolerancing can lead to substantial savings and efficiency improvements in production. ↩

-

Learn about equivalent material substitutions to optimize costs and improve efficiency in your projects. ↩