Struggling with inconsistent parts or slow production? Manual errors costing valuable time and money? CNC machining offers the precision and reliability you need for perfect results, every time.

CNC machining services stand out because they provide superior precision, unmatched speed, and excellent repeatability. They handle complex designs with ease and significantly reduce human error, leading to higher quality parts and more efficient production, especially for demanding projects.

You might be wondering what specific benefits make CNC the go-to choice in modern manufacturing. It's more than just automation; it's about unlocking new levels of capability and efficiency. Let's dig into the details and see why it consistently outperforms older methods.

What are the advantages of CNC machining?

Need consistent quality, especially for intricate parts? Tired of the limitations you face with traditional manufacturing methods? CNC machining delivers the accuracy and versatility required to solve these production headaches.

The key advantages are high precision down to very tight tolerances, excellent repeatability across thousands of units, increased speed, versatility with materials and complex shapes, and automation that reduces labor costs and errors. This makes it ideal for today's demanding manufacturing needs.

Let's dive deeper into these benefits. When I first started in a CNC shop, I was amazed by the difference compared to the manual machines I'd used before. The level of detail and consistency was just on another level.

Precision and Repeatability

CNC machines operate based on precise digital instructions. This means they can achieve tolerances1 that are incredibly difficult, if not impossible, to hit consistently with manual methods. We're talking about measurements often finer than a human hair. Crucially, once programmed, a CNC machine can produce the exact same part thousands of times with minimal variation. This repeatability is vital for industries like aerospace, medical, and automotive, where even tiny deviations can have serious consequences. I remember a client needing thousands of identical small components for a medical device; manual machining just couldn't guarantee the required consistency, but our CNC machines handled it perfectly.

Speed and Efficiency

Computers control the cutting tools, optimizing paths and speeds far beyond human capability. Tool changes are often automated, and machines can run 24/7 with minimal supervision ("lights-out manufacturing2"). This dramatically reduces cycle times and increases throughput compared to manual processes, which require constant operator attention and are prone to fatigue-related slowdowns or errors. Faster production means quicker time-to-market and lower per-part costs.

Versatility and Complexity

CNC machines aren't limited to simple shapes. Multi-axis machines (3, 4, or even 5-axis) can create incredibly complex geometries, undercuts, and organic shapes directly from a CAD file3. They also work with a vast range of materials, from plastics and aluminum to hardened steels and exotic alloys, without needing entirely different setups for each one. This flexibility opens up huge possibilities for designers and engineers.

Why do engineers like CNC machining?

Are you an engineer facing tough design constraints? Worried about manufacturability issues or slow prototype turnaround times? CNC machining offers the freedom, speed, and reliability needed to innovate with confidence.

Engineers appreciate CNC machining because it accurately translates complex digital designs (CAD) into physical parts. It gives them greater design freedom, enables rapid prototyping for faster iteration, offers broad material flexibility, and delivers predictable, high-quality results, simplifying the entire product development cycle.

As someone who works closely with designers and engineers like Jacky, I see firsthand why they rely so heavily on CNC. It bridges the gap between their digital vision and a tangible product seamlessly.

Bridging CAD to Reality

The direct link between Computer-Aided Design (CAD)4 software and Computer-Aided Manufacturing (CAM) software used by CNC machines is a game-changer. Engineers can design complex parts on their computers, and the CNC machine can produce them with high fidelity. This tight integration reduces the chance of errors creeping in during interpretation, unlike manual processes where an operator reads a drawing. It ensures the final part matches the engineer's intent precisely.

Design Freedom and Iteration

Knowing that complex shapes can be reliably manufactured encourages engineers to push design boundaries. They aren't as constrained by traditional manufacturing limitations. Furthermore, CNC is fantastic for prototyping. Need to test a new design? You can machine a single prototype or a small batch quickly, test it, make digital adjustments in the CAD file, and machine the revised version rapidly. This iterative process is much faster and more cost-effective than creating molds or complex manual setups for each version. I worked with an automotive engineer who iterated a bracket design three times in a week using our CNC services, something unthinkable with casting prototypes.

Material Choice and Predictability

Engineers often need specific materials for performance requirements. CNC machining works with almost any machinable material, giving them the flexibility to choose the best option without worrying if it can be shaped correctly. Because the process is controlled and repeatable, engineers can predict the outcome, tolerances, and surface finish with high confidence, which is crucial for performance calculations and quality control.

What are the advantages of CNC over manual?

Are you frustrated by the inconsistencies that often come with manual machining? Losing valuable time and materials because of human error? CNC automation effectively eliminates these issues, offering reliable and repeatable results you can count on.

CNC machining clearly surpasses manual methods through superior accuracy, much faster production speeds, and unwavering consistency. Automation drastically cuts down on operator fatigue and errors, makes complex geometries possible, and enables unattended operation, significantly boosting overall productivity and reliability.

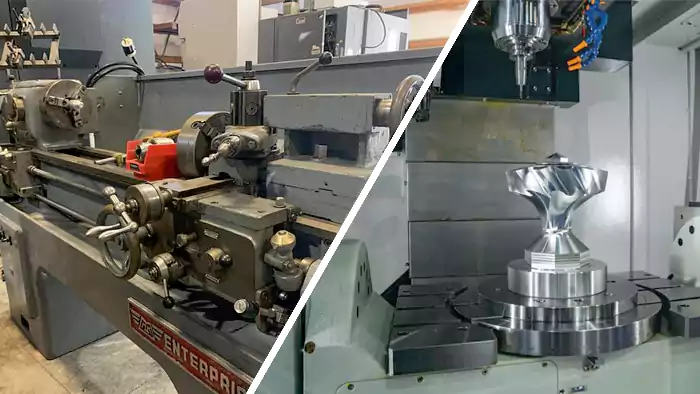

Having spent time operating both manual and CNC machines early in my career, the difference is stark. While manual machining requires skill and artistry, CNC brings a level of performance that manual methods simply cannot match for most production scenarios.

Accuracy and Consistency

A skilled manual machinist can produce high-quality parts, but maintaining that same level of precision across hundreds or thousands of units, or even across different shifts, is extremely challenging. Fatigue, slight variations in setup, and individual technique differences lead to inconsistencies. CNC machines, guided by code, eliminate these variables. They execute the same precise motions every single time, ensuring every part meets the required specifications.

Speed and Productivity

Manual machining is inherently slower. The operator needs to constantly monitor progress, make adjustments, change tools by hand, and measure features. CNC machines automate all of this. They cut faster, move between features quicker, and change tools automatically. Plus, they can often run unattended for extended periods, even overnight. This leads to significantly higher output and lower labor costs per part. I remember seeing our first CNC machine outproduce three manual mills combined for a specific job.

Complexity and Capability

Making complex curves, intricate patterns, or parts requiring simultaneous multi-axis movement is exceptionally difficult or impossible manually. CNC machines, especially 4-axis and 5-axis models, excel at this. They follow programmed toolpaths precisely, enabling the creation of geometries that would be unthinkable with manual control alone. This opens up possibilities for more advanced and optimized designs.

Safety

CNC machines typically enclose the work area, protecting operators from flying chips and cutting fluid. Since the process is automated, the operator spends less time in close proximity to moving tools, reducing the risk of accidents compared to manual machining.

What makes CNC machines more capable than traditional machines like manual lathes?

Are you feeling limited by the capabilities of basic, manually operated machines? Finding traditional lathes too slow and perhaps prone to errors for your more complex jobs? CNC technology offers far greater versatility, precision, and automation.

Compared to traditional standalone machines like manual lathes or mills, CNC machines offer integrated multi-axis control for complex shapes, full automation for higher throughput and consistency, better inherent precision, and the flexibility to quickly switch between jobs using pre-written programs.

Think of a manual lathe. It's a fantastic tool for creating cylindrical parts, and a skilled operator can do great work. But its capabilities are inherently focused. CNC machining centers, including CNC lathes and mills, take this to a whole new level.

Integrated Multi-Axis Control

A manual lathe typically works on two axes (X and Z) to shape rotating parts. A manual mill usually works in three linear axes (X, Y, Z). CNC machines often combine these capabilities and add rotational axes (A, B, C).

- CNC Lathes: Can have live tooling (rotating cutters like drills or end mills) and sub-spindles, allowing them to perform milling operations on the part without moving it to another machine.

- CNC Mills: Progress from basic 3-axis (moving the tool or table in X, Y, Z) to 4-axis (adding one rotation) and 5-axis (adding two rotations). This allows the tool to approach the workpiece from almost any angle, enabling the creation of highly complex shapes, undercuts, and contours in a single setup. Imagine trying to machine a turbine blade on a manual mill – it’s practically impossible, but straightforward on a 5-axis CNC.

Automation and Efficiency

Beyond just controlling the cutting, CNC machines automate tool changes (with Automatic Tool Changers - ATCs), coolant management, and sometimes even part loading/unloading. Complex operations that might require multiple setups and different machines manually can often be done in one clamping on a sophisticated CNC machine like a mill-turn center. This drastically reduces setup time, potential for errors from re-clamping, and overall production time.

Programming vs Manual Skill

While manual machining relies heavily on the operator's skill and feel, CNC machining relies on a well-written program. This makes the process highly repeatable and less dependent on finding highly skilled operators (though skilled CNC operators and programmers are still essential!). It also allows for easy recall of jobs – just load the program, set up the tools and material, and run the part again months later with identical results.

Conclusion

In short, CNC machining services provide superior precision, speed, repeatability, and the ability to create complex parts efficiently. It's the clear winner for modern, high-quality manufacturing needs.

-

Learn about tolerances in manufacturing and their critical role in ensuring product quality and performance across industries. ↩

-

Explore this link to understand how lights-out manufacturing enhances efficiency and reduces costs in production. ↩

-

Learn about the crucial role of CAD files in CNC machining, enabling precise and complex designs to be translated into physical products. ↩

-

Explore this link to understand how CAD enhances design accuracy and efficiency in engineering projects. ↩