Fasteners often look simple, so they are designed last. When they fail, the failure spreads fast and costs time, money, and trust.

Custom motorcycle fasteners must be designed as load-bearing components, not catalog items, because material, geometry, and fit directly control safety, fatigue life, and long-term reliability in vehicle systems. This critical role makes informed sourcing of custom motorcycle fasteners — evaluating manufacturing methods, cost, and supplier choices — a key strategy to mitigate supply chain and performance risks from the very start.

I have spent years fixing problems that started with a small bolt choice. Once a fastener fails in testing or in the field, redesign is expensive. That is why I now treat fasteners as part of the core mechanical design.

When Do Standard Fasteners Fail in Motorcycle and Vehicle Design?

Standard fasteners are built for general use. Vehicle systems are never general. Vibration, tight space, and mixed materials expose weaknesses very quickly.

Standard fasteners fail when load paths, vibration levels, or installation space fall outside the assumptions used in catalog designs.

In my experience, failure rarely comes from one big mistake. It comes from many small compromises. A bolt is slightly too long, so thread engagement is short. A washer is removed to save space. A coating is chosen late and does not match the environment.

Why vehicle loads are different from static structures

Motorcycles and light vehicles see cyclic loads1 every second. Engines vibrate. Roads excite frames. Brakes apply shock loads. These forces cause micro-movement at the joint. Over time, this leads to fatigue cracks2 or loosening. Static load calculations alone do not reflect these effects.

Common warning signs during design reviews

I watch for slotted holes, thin flanges, and mixed materials like steel into aluminum. These designs often need custom fasteners with controlled shanks, special heads, or defined preload ranges. Standard parts rarely fit these needs well.

Which Fastener Types Are Most Often Redesigned for Vehicles?

Not all fasteners need custom design. Some types appear again and again in vehicle projects when problems arise.

Bolts, studs, and special threaded fasteners are the most commonly redesigned parts in motorcycle and vehicle systems.

Over time, I noticed patterns. Engineers often start by redesigning one bolt. Later, they redesign an entire joint system to stabilize performance.

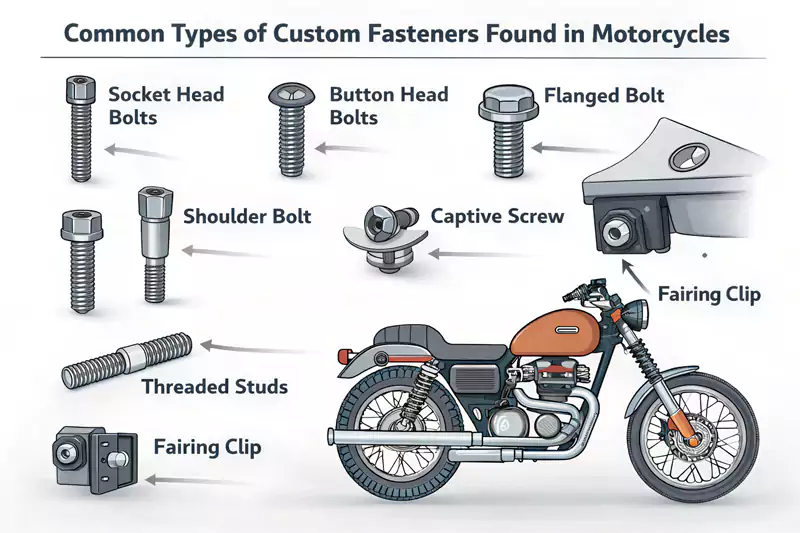

Bolts, screws, nuts, and washers

Custom bolts often include reduced shanks, integrated washers, or low-profile heads. These features improve load distribution and save space. Nuts may include locking features or thin walls for clearance. Washers are often merged into the bolt head to reduce part count.

Studs and special threaded fasteners

Studs are used where parts are assembled many times. They protect base threads and improve alignment. Special thread forms help control preload in vibration-heavy joints.

Why auxiliary fasteners also matter

Clamps and non-threaded fasteners hold hoses, cables, and covers. When they fail, systems leak or rub. Custom designs often extend service life and reduce maintenance effort.

How Does Material Choice Affect Strength, Weight, and Fatigue Life?

Material choice defines what is possible and what is not. Geometry and coatings can help, but material sets the limits.

Fastener material controls load capacity, fatigue resistance, corrosion behavior, and machining cost at the same time.

I always tell engineers that no material is perfect. Each one solves one problem and creates another.

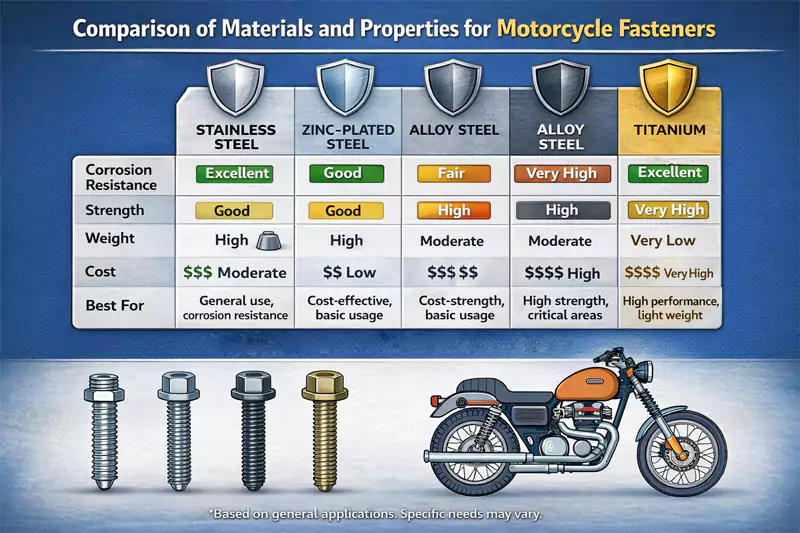

Different fastener materials present distinct trade-offs in strength, weight, corrosion resistance, and fatigue behavior.

A comparison of commonly used motorcycle fastener materials helps clarify how these characteristics influence performance under real riding conditions.

Carbon steel, alloy steel, and stainless steel

Carbon steel is easy to machine and low cost. It needs good coating control. Alloy steel increases strength and fatigue life, but heat treatment must be stable. Stainless steel resists corrosion but often sacrifices strength and machinability.

Aluminum and titanium for lightweight designs

Aluminum fasteners reduce mass but require careful preload control. Titanium offers high strength and corrosion resistance with low weight, but machining time and cost increase sharply.

Material trade-offs engineers often miss

Harder materials raise tool wear and lead time. Softer materials deform under load. These trade-offs must be discussed early, not after testing fails.

How Do Threads, Dimensions, and Tolerances Affect Assembly Fit?

Fit problems are often blamed on assembly. In reality, they start at the drawing stage.

Thread choice, tolerance class, and engagement length directly affect preload stability and joint safety.

I have reviewed many drawings where the fastener looked correct but failed in practice.

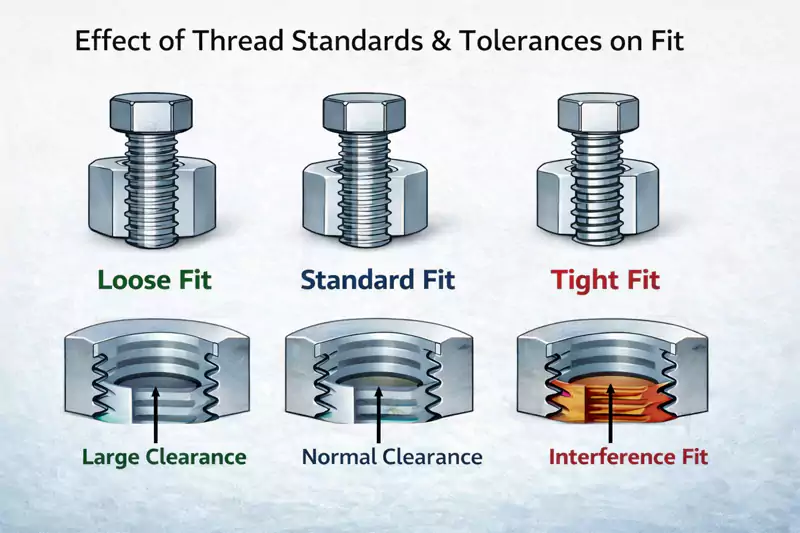

Thread standards and engagement length

Metric ISO threads3 dominate vehicle design. Still, pitch and tolerance class vary. Short engagement increases stress. Long engagement increases cost and galling risk.

Tolerances and real assembly behavior

Tight tolerances improve alignment but increase machining time. Loose tolerances reduce cost but risk uneven load sharing. The right balance depends on joint function.

Fit issues seen during testing

Cross-threading, uneven seating, and preload scatter often trace back to poor tolerance planning. Custom fasteners allow tighter control where it matters most.

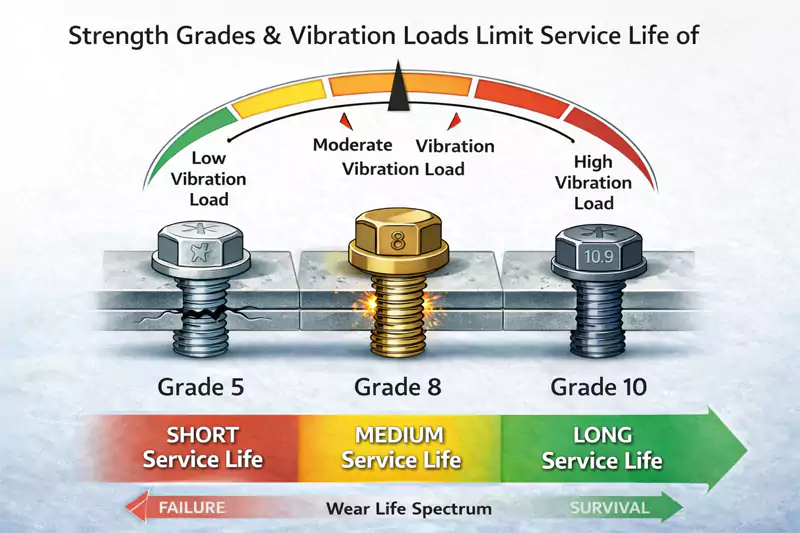

How Do Strength Grades and Vibration Loads Limit Fastener Life?

Strength numbers look simple. Real life is not.

Higher strength does not always mean longer life, especially in vibration-dominated motorcycle joints.

This is one of the most misunderstood areas in fastener design.

Strength grades and fatigue behavior

High strength grades increase static capacity. They often reduce ductility. In vibration, brittle behavior accelerates crack growth and early failure.

Fastener strength grades define the mechanical limits of bolts and screws under tensile and cyclic loading.

Understanding how these strength grades are defined and applied provides useful context for evaluating fastener performance in high-vibration motorcycle environments

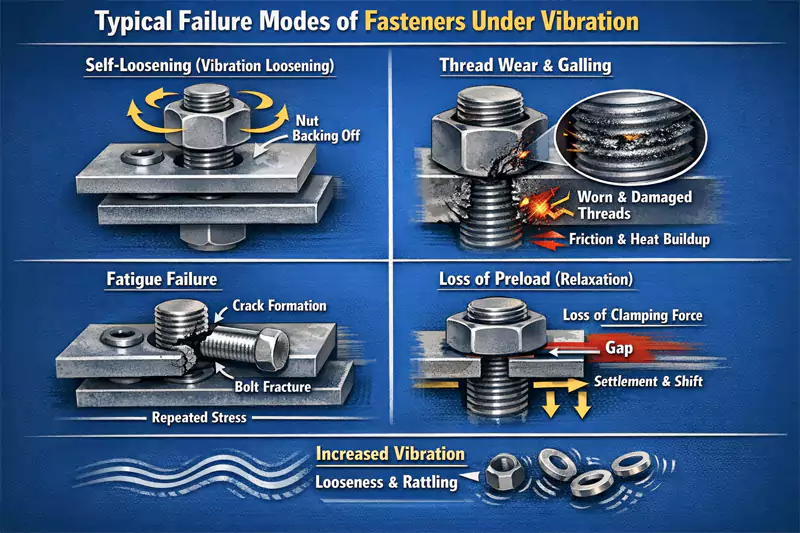

Vibration, preload loss, and loosening

Vibration causes micro-slip at interfaces. If preload drops, fatigue damage rises fast. Thread form and surface finish both influence this process.

Case Study: Custom Frame Mount Bolt Redesign and Performance Outcome

I once worked on a motorcycle frame mount bolt that failed early in fatigue testing. The original design focused only on maximum strength. The redesigned fastener focused on load distribution and durability.

| Parameter | Original Design | Custom Redesign |

|---|---|---|

| Material | 35 Steel | 42CrMo4 Alloy Steel |

| Diameter | M8 | M8 |

| Shank Design | Fully threaded | Partial smooth shank |

| Strength Grade | 12.9 | 10.9 |

| Surface Finish | Black oxide | Zinc-nickel coating |

| Fatigue Life | < 50,000 cycles | > 300,000 cycles |

| Test Result | Early crack failure | Passed full validation |

By reducing stress concentration, improving corrosion resistance4, and stabilizing preload, the redesigned fastener increased fatigue life5 by more than six times. The customer eliminated repeated test failures and moved into production without changing the surrounding structure.

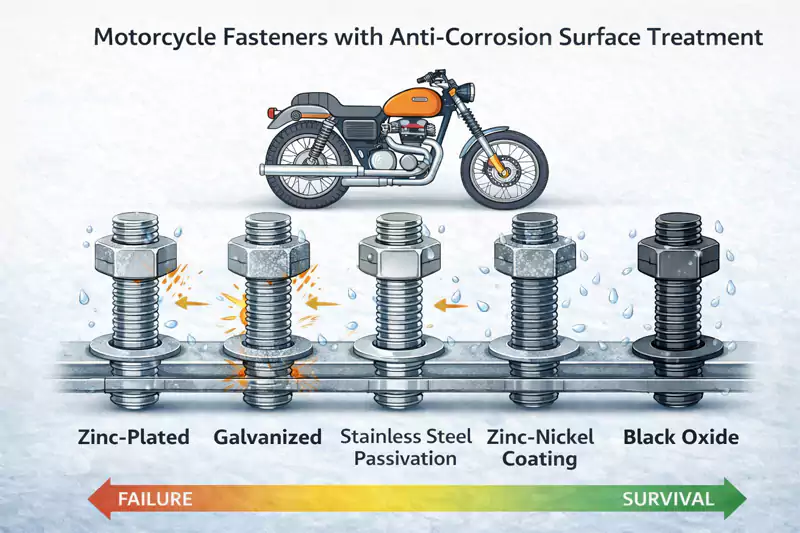

How Should Fasteners Be Designed for Corrosion and Outdoor Use?

Corrosion rarely causes instant failure. It quietly reduces life until failure seems sudden.

Surface treatment must be treated as a functional design parameter, not a cosmetic choice.

I have seen strong fasteners fail because corrosion reduced preload over time.

Common coatings and their limits

Zinc plating offers basic protection. Black oxide offers almost none. Phosphate improves lubrication but needs oil or paint to protect against rust.

Advanced finishes for harsh environments

Zinc-nickel and PVD coatings improve corrosion resistance and friction control. They cost more but protect long-term joint performance.

Designing for real environments

Road salt, humidity, and heat cycles demand higher standards. Coating thickness, adhesion, and post-treatment all affect durability.

Conclusion

Designing reliable motorcycle fasteners requires a balanced approach that considers load conditions, vibration, material behavior, and long-term durability.

However, even well-defined engineering requirements must be supported by precise execution to perform as intended in real-world applications.

Custom motorcycle fastener manufacturing bridges the gap between design intent and functional performance by integrating material selection, strength standards, machining accuracy, and quality control into a consistent production process.

-

Understanding cyclic loads is crucial for designing vehicles that can withstand repeated stress and avoid failure. ↩

-

Exploring fatigue cracks helps in recognizing potential failure points in designs, ensuring better durability and safety. ↩

-

Understanding Metric ISO threads is crucial for ensuring proper fastener performance in vehicle design. ↩

-

Exploring corrosion resistance can help you choose the right materials for enhanced durability and performance in fastener design. ↩

-

Understanding fatigue life is crucial for ensuring the longevity and reliability of fasteners in various applications. ↩