Need to turn a complex 3D design into a physical part? Traditional methods can be slow and inaccurate, failing to meet the tight tolerances your project demands.

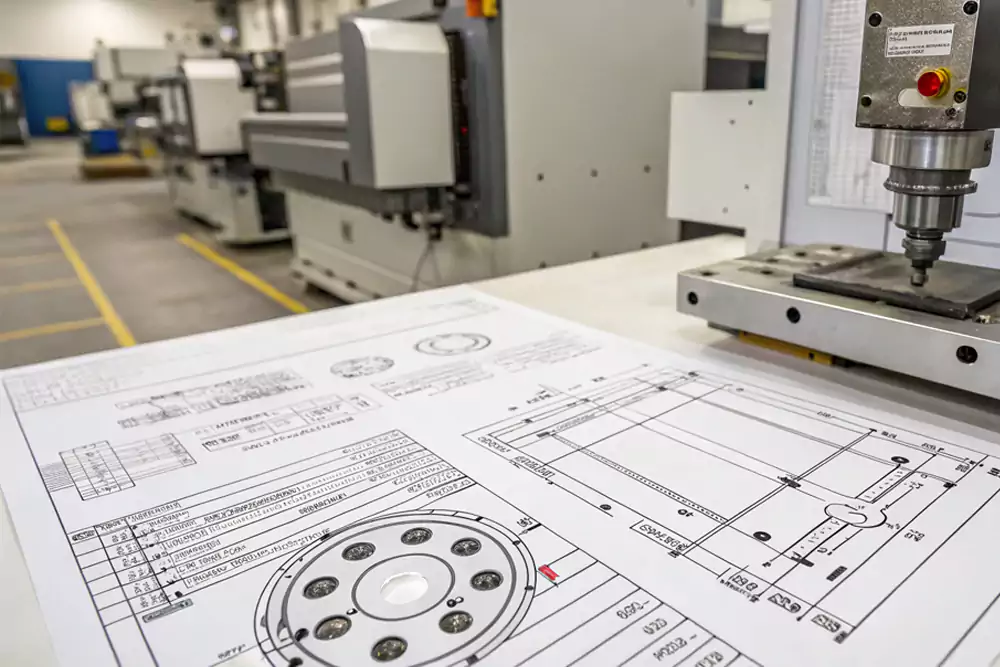

CNC milling is a subtractive manufacturing process that uses a rotating multi-point cutting tool to precisely remove material from a workpiece, creating a custom-designed part with exceptional accuracy.

Having run my own CNC machining shop for years, I know that CNC milling is the backbone of modern manufacturing. For engineers who design complex robotics and automation systems, milling is about turning a digital concept into a functional, high-precision reality. It’s about more than just cutting metal; it’s a deep understanding of precision, speed, and consistency. I've learned that the right process and material selection significantly impact part quality and cost. This guide is built on my hands-on experience, designed to help engineers and procurement managers understand the core principles of CNC milling and how to successfully source high-quality precision parts.

What is CNC Milling?

What does "CNC milling" actually mean? How does a computer-controlled machine transform a solid block of metal or plastic into a finished component?

CNC milling is an automated process where a computer guides a rotating cutting tool to remove material from a stationary workpiece according to a pre-programmed design.

Diving Deeper into the Definition

CNC stands for Computer Numerical Control. At its core, CNC milling is a subtractive manufacturing process. This means we start with a solid block of material (the "workpiece" or "blank") and strategically cut material away to reveal the final part. This is the opposite of additive manufacturing (like 3D printing), which builds a part layer by layer.

The "milling" part of the name refers to the specific action of using a rotating multi-point cutting tool. Think of an end mill as a highly advanced drill bit that can cut sideways as well as downwards. This tool spins at high speeds, and the machine moves it along multiple axes to shave away material with incredible precision.

The entire process is driven by a digital design. An engineer creates a 3D CAD model of the part. That model is then used to generate a set of instructions, called G-code, which is the language the CNC machine understands. The machine follows this code perfectly, ensuring every part produced is an exact replica of the digital design.

How Does CNC Milling Work?

What is the actual step-by-step process? How do we go from a digital file on a computer to a finished, physical part in our hands?

The process starts with a 3D CAD design, which is converted into G-code. A block of material is secured in the CNC machine, which then executes the code, using a spinning tool to cut the part.

Diving Deeper into the Workflow

The CNC milling process is a systematic workflow that ensures precision and repeatability. Understanding these steps is key to designing parts that are optimized for manufacturing.

Here's a breakdown of the process in my shop:

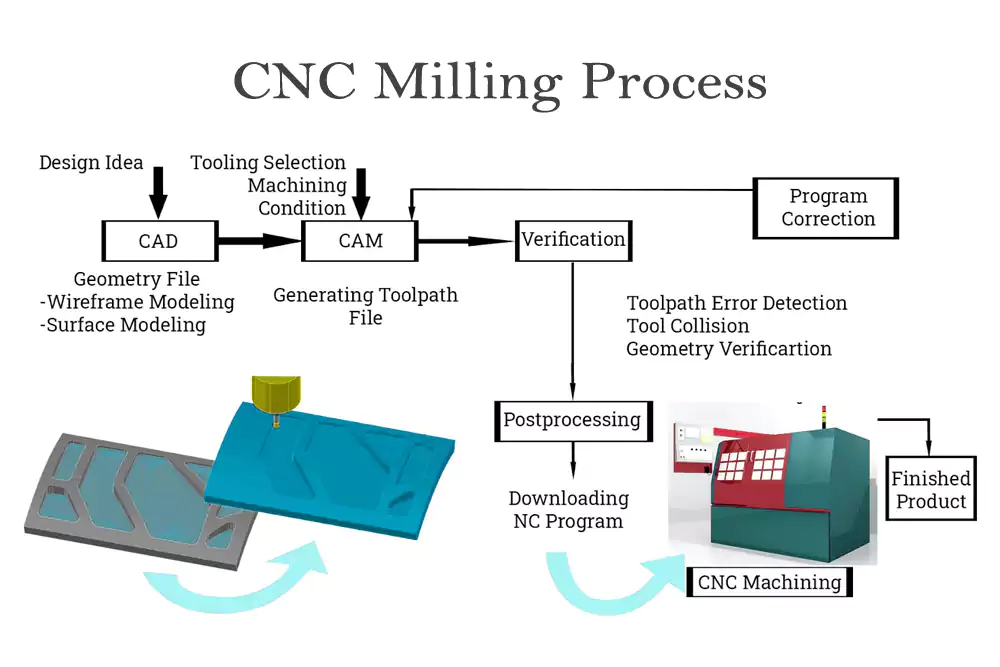

- CAD Model Creation: It all starts with the client's 3D CAD (Computer-Aided Design) file. This is the digital blueprint of the final part.

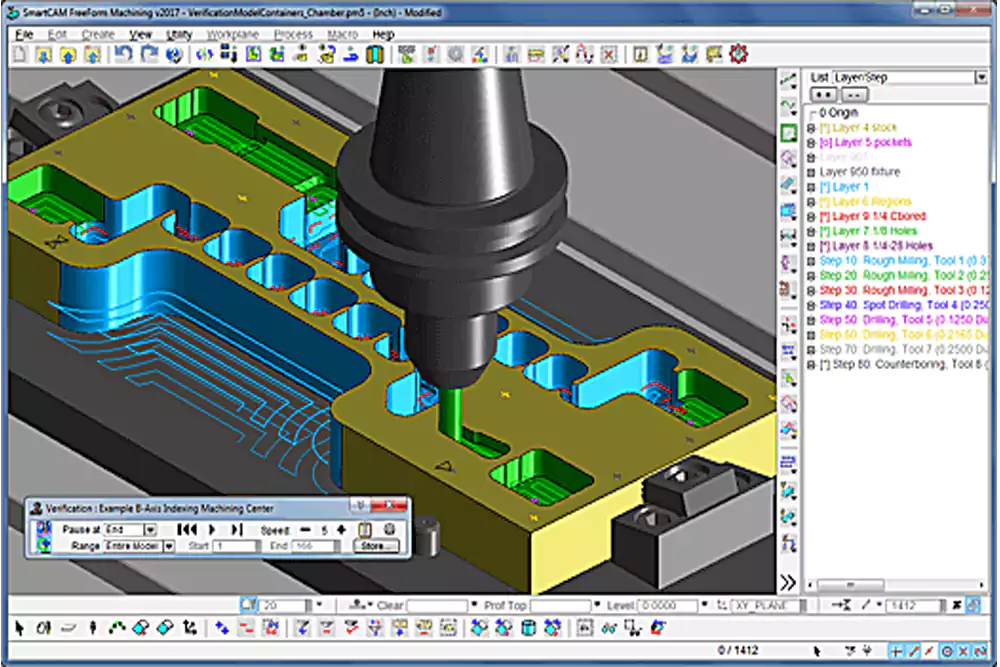

- CAM Programming: The CAD file is imported into CAM (Computer-Aided Manufacturing) software. A skilled programmer then uses the software to plan the entire machining operation. This involves selecting the right cutting tools, setting the cutting speeds and feeds, and generating the optimal toolpaths. The output of this stage is the G-code file.

- Machine Setup: A block of the chosen material is securely clamped onto the machine's worktable. The CNC machinist then loads the required cutting tools into the machine's tool holder and sets the "work zero"—the precise starting point for the machining operation.

- The Milling Operation: The machinist loads the G-code program into the CNC controller. When the "cycle start" button is pushed, the machine takes over. It automatically executes the program, moving the cutting tool along the programmed paths to precisely remove material. The machinist's role here is to supervise the process, ensuring everything runs smoothly.

- Quality Inspection1: After the part is finished, it is removed from the machine, cleaned, and then carefully inspected using precision measuring tools like calipers, micrometers, and Coordinate Measuring Machines (CMMs) to ensure every dimension is within the specified tolerances.

What Are the Advantages of CNC Milling?

Why is CNC milling such a dominant force in manufacturing? What are the key benefits that make it the go-to process for creating high-quality parts?

The primary advantages of CNC milling are its exceptional precision and repeatability, its ability to create complex geometries, and its compatibility with a vast range of production-grade materials.

Diving Deeper into the Benefits

From my years on the shop floor, I can tell you that CNC milling's value comes from a powerful combination of factors that other processes struggle to match. It's not just about cutting metal; it's about delivering reliable, high-quality components efficiently.

Here are the key advantages:

- Precision and Repeatability2: This is the number one benefit. A CNC mill can produce parts with tolerances as tight as ±0.001 inches (or even tighter). Because the process is computer-controlled, it can produce thousands of parts that are all virtually identical. This level of consistency is critical for modern assembly and product performance.

- Complex Geometries: With the advent of 5-axis machines, CNC milling can create incredibly complex shapes, contours, and undercuts that would be impossible with manual methods. This gives engineers immense design freedom.

- Material Versatility3: Unlike some other processes, CNC milling works with a huge variety of production-grade materials. We can mill everything from soft plastics to hardened tool steels and superalloys, allowing engineers to choose the perfect material for their application.

- Scalability: The process is perfectly suited for any volume. It's efficient enough for a single rapid prototype and scalable enough for full production runs of thousands of parts, all with the same high level of quality.

What Are the Common Types of CNC Milling Machines?

Are all milling machines the same? What are the different types of CNC mills, and how do their capabilities differ for creating complex parts?

The most common types of CNC mills are 3-axis, 4-axis, and 5-axis machines. The number of axes determines the complexity of the parts the machine can produce in a single setup.

Diving Deeper into Machine Types

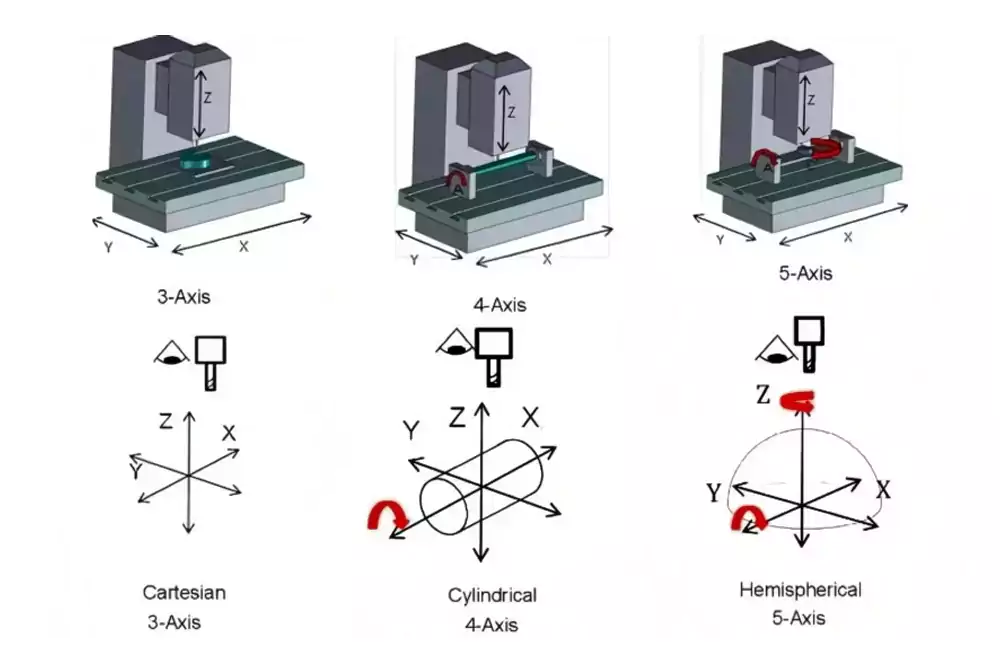

The "axis" count of a CNC machine refers to the number of directions the cutting tool or workpiece can move. As a shop owner, having a range of machines is critical to being able to produce any part a client might design.

| Machine Type | Description of Movement | Best For |

|---|---|---|

| 3-Axis CNC Mill | This is the most basic and common type. The cutting tool moves in three linear directions: X (left-right), Y (front-back), and Z (up-down). | Parts with relatively simple geometry that can be machined from the top down. Ideal for plates, blocks, and simple enclosures. |

| 4-Axis CNC Mill | This machine adds a rotational axis (the A-axis) to the standard three linear axes. This allows the workpiece to be rotated during the machining process. | Parts that have features on their sides, such as drilling holes around a cylinder. It reduces the number of manual setups required. |

| 5-Axis CNC Mill | This is the most advanced type of milling machine. It adds two rotational axes to the three linear axes. This allows the cutting tool to approach the workpiece from any angle in a single setup. | Extremely complex and contoured parts, such as those found in the aerospace and medical industries. It allows for the creation of organic shapes and undercuts that are impossible on a 3-axis machine. |

In my experience, while 3-axis milling is the workhorse for many jobs, our 5-axis capabilities are what allow us to take on the most challenging and innovative projects for our clients.

Case Study: Precision Milling a Robotic Arm Joint?

How does CNC milling handle a real-world, high-precision part? Let's look at an example of a complex component we manufactured.

CNC milling is ideal for parts like robotic arm joints, where a single, complex component requires extremely tight tolerances on multiple faces to ensure smooth and accurate movement.

Diving Deeper into a Real-World Application

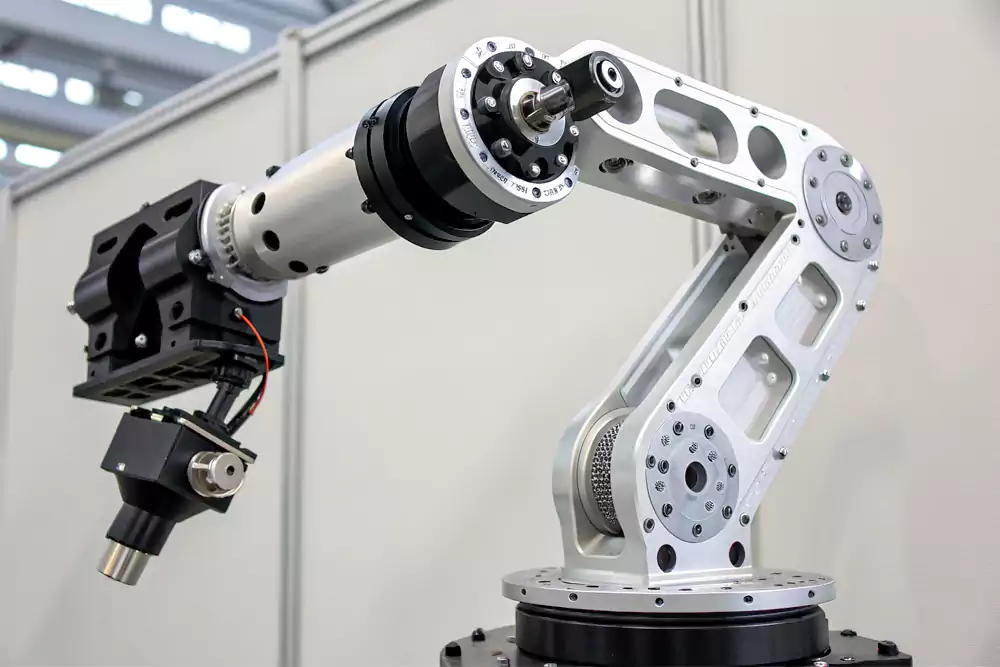

A client in the industrial automation sector came to us with a design for a new robotic arm joint. The part was incredibly complex and acted as the "knuckle" of the arm, housing both motors and bearings. It required exceptional strength, light weight, and, most importantly, extreme precision to prevent any "slop" or vibration in the robot's movement.

This was a perfect job for our 5-axis CNC mills4. Machining the part from a single block of 7075 aluminum ensured maximum strength.

| Parameter | Specification | Purpose |

|---|---|---|

| Material: | 7075-T6 Aluminum5 | High strength-to-weight ratio for robotic applications. |

| Key Tolerances: | Bearing Bore Diameter: ±0.008 mm | Ensures a precise press-fit for the bearings, eliminating play. |

| True Position of Mounting Holes: Ø 0.025 mm | Guarantees perfect alignment between the robotic arm segments. | |

| Surface Finish: | Ra 0.8 µm on bearing faces | Provides a smooth surface for bearing contact, reducing wear. |

| Finishing: | Type II Black Anodizing | Provides a hard, wear-resistant, and cosmetic finish. |

By using a 5-axis machine, we were able to machine all the critical features—the bearing bores, the motor mounts, and the complex external contours—in a single setup. This was essential for achieving the tight positional tolerances between the features. The final part was not only incredibly accurate but also 20% lighter than the previous multi-part assembly it replaced.

What Are the Best Materials for CNC Milling?

What materials can you use in a CNC mill? What are the most common metals and plastics used for creating custom parts?

The best materials for CNC milling include a wide range of metals, such as aluminum, steel, and stainless steel, and engineering plastics, like ABS, Delrin, and polycarbonate.

Diving Deeper into Material Selection

The ability to work with a huge variety of production-grade materials is a major advantage of CNC milling. This allows an engineer to choose a material with the exact properties their application requires. The material choice has a big impact on the cost and speed of machining.

Here are some of the most common materials we work with:

Metals

- Aluminum (e.g., 6061, 7075): This is the most popular material for CNC milling. It has an excellent strength-to-weight ratio, is naturally corrosion-resistant, and is very easy to machine, which keeps costs down.

- Steel (e.g., 1018, 4140): Used when high strength, hardness, and durability are required. Alloy steels like 4140 can be heat-treated after machining to achieve even greater hardness.

- Stainless Steel (e.g., 304, 316): Chosen for its excellent corrosion resistance. It is essential for parts used in medical, marine, or food-grade applications. It is tougher to machine than aluminum, which increases the cost.

Plastics

- ABS: A common, low-cost plastic with good impact resistance. Great for prototyping and general-purpose enclosures.

- Delrin® (POM): An excellent engineering plastic with high stiffness, low friction, and great dimensional stability. It is often used for gears, bushings, and other precision mechanical parts.

- Polycarbonate (PC): Known for its incredible toughness and impact resistance. It is often used for transparent parts like machine guards and lenses.

What Are the Key Design Considerations for CNC Milling?

How can you design a part to make it easier and more affordable to machine? What are some key "Design for Manufacturability" (DFM) tips?

Key design considerations for CNC milling include adding radii to internal corners, avoiding deep and narrow pockets, using standard hole sizes, and specifying tolerances only as tight as necessary.

Diving Deeper into Design for Manufacturability (DFM)6

As a machinist, I can tell you that a few small changes in a part's design can have a huge impact on its cost. When an engineer understands these basic DFM principles, it makes the entire manufacturing process smoother and more affordable.

Here are some of the most important tips:

- Add Radii to Internal Corners: A spinning milling tool is round, so it cannot create a perfectly sharp internal corner. Always design your internal pockets with a corner radius. A larger radius is always better and cheaper, as it allows for a larger, more rigid tool to be used.

- Avoid Deep, Narrow Pockets: Pockets that are very deep relative to their width require long, thin tools. These tools are prone to vibration and can break easily, forcing us to use very slow cutting speeds, which dramatically increases the machining time and cost. A good rule of thumb is to keep the depth of a pocket to no more than 4 times its width.

- Use Standard Hole Sizes: Design your parts with standard drill bit sizes and standard thread sizes (like M6 or 1/4-20) whenever possible. Using a non-standard size may require us to order a special, expensive tool.

- Specify Tolerances Wisely: This is one of the biggest cost drivers. Only apply very tight tolerances to the features that are absolutely critical for the part's function. Loosening the tolerances on non-critical features will significantly reduce the machining and inspection time, which directly lowers the cost of the part.

What Should You Consider When Customizing Precision Parts?

When sourcing custom milled parts, what are the key factors you should consider to ensure you get the quality and service you need?

When customizing precision parts, consider your supplier's technical capabilities (like 5-axis machining), their quality control systems, their communication and DFM support, and their ability to handle both prototypes and production.

Diving Deeper into Sourcing Considerations

Sourcing a manufacturing partner is a critical decision. It's not just about getting the lowest price; it's about finding a reliable partner who can deliver consistent quality and support your engineering team.

Based on my years of working with clients, here are the most important things to consider:

- Technical Capabilities:

- Does the supplier have the right machines for your parts? If your parts are complex, you should look for a shop with 5-axis milling capabilities.

- Do they have experience with your chosen material? Machining titanium is very different from machining aluminum.

- Quality Control Systems:

- A serious supplier should be ISO 9001 certified. This shows they have a robust quality management system in place.

- Ask about their inspection equipment. Do they have a Coordinate Measuring Machine (CMM)? A CMM is essential for accurately verifying the dimensions of complex parts.

- Will they provide a full inspection report with your order?

- Communication and Engineering Support:

- A good partner is more than just a machine shop; they are an extension of your engineering team. Do they offer Design for Manufacturability (DFM) feedback to help you optimize your design?

- How responsive are they? Fast and clear communication is key to keeping your project on schedule.

- Flexibility and Scalability:

- Can the supplier handle both your rapid prototype needs and your future production runs? Working with a single partner who can scale with you simplifies your supply chain and ensures consistency as your project matures.

Conclusion

CNC milling is a precise, versatile, and powerful manufacturing process. Understanding its fundamentals is the key to creating high-quality, cost-effective custom parts for any application.

-

Learn about the critical role of quality inspection in ensuring precision and maintaining manufacturing standards. ↩

-

Understanding the importance of precision and repeatability can enhance your manufacturing processes and product quality. ↩

-

Exploring material versatility can help you select the best materials for your projects, optimizing performance and cost. ↩

-

Explore this link to understand how 5-axis CNC mills enhance precision and efficiency in complex machining tasks. ↩

-

Learn more about 7075-T6 Aluminum's strength and lightweight benefits for industrial applications. ↩

-

Exploring best practices in DFM can help you optimize your designs for cost-effective manufacturing.