Table of Contents:

Intelligent Manufacturing in CNC: Real Shop Floor Results That Actually Matter

- January 18, 2025

- Tony

- Last updated on November 10, 2025 by Lucy

1. What is Intelligent Manufacturing?

You hear the term “Intelligent Manufacturing” everywhere. For procurement and engineering, you don’t care about the buzzword—you care about what it delivers: tighter tolerances, maximum consistency, and parts that arrive on time without excuses.

Intelligent Manufacturing isn’t just about robots; it’s about connecting every machine, sensor, and CMM to a single data feedback loop. This automation and data-driven approach virtually eliminates human error, predicts maintenance failures, and ensures dimensional consistency across every batch, reducing lead times and cutting scrap costs.

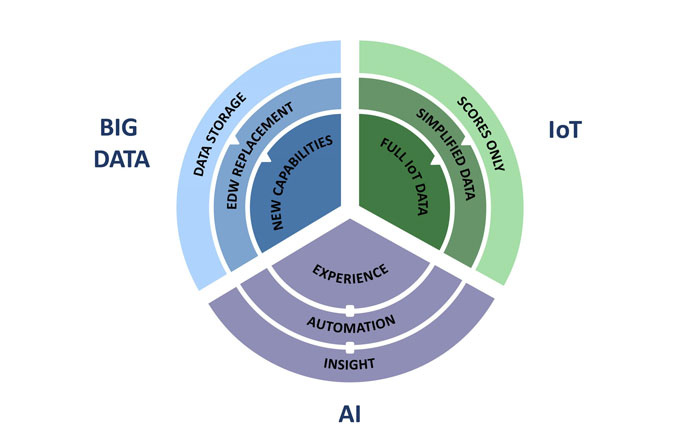

Intelligent manufacturing is also called smart manufacturing. Uses advanced technologies like LOT, AI, and Big Data to make production faster, more flexible, and more precise.

It automates processes, optimizes workflows, and improves decision-making by using real-time data.

Why is intelligent Manufacturing Used in CNC Machining?

It helps CNC machining in several ways:

Real-Time Adjustments

Sensors and data allow machines to adjust automatically, ensuring accuracy.

Automation

Reduces manual work and speeds up production with automated equipment.

Preventive Maintenance

Predicts equipment issues and prevents downtime by scheduling repairs in advance.

Smart manufacturing makes CNC machining more efficient, accurate, and less reliant on manual work, pushing the industry toward greater automation.

2. The combination of intelligent manufacturing and CNC machining

Traditional CNC Machining Challenges

CNC machining itself is a highly precise manufacturing process that is widely used in the processing of various types of mechanical parts.

However, traditional CNC machining faces challenges like high costs, low efficiency, and a heavy reliance on operator experience.

Intelligent manufacturing enhances traditional CNC machining

Smart manufacturing addresses these challenges by introducing technologies such as automated control, real-time monitoring, and data analytics.

These innovations optimize CNC machining, making production more flexible and efficient. With intelligent systems, CNC machining can automatically adjust parameters and reduce manual input, resulting in improved overall efficiency.

📌Case Study: Aerospace Bracket Production

We had an aerospace client needing 500 aluminum mounting brackets with ±0.01mm tolerances. Their previous supplier struggled with 15% scrap rates and consistent 2-week delays.

The Challenge:

- Part: 7075 Aluminum aircraft brackets

- Tolerance: ±0.01mm on critical bore diameters

- Scrap rate: 15% (industry average: 5%)

- Lead time: Consistently 2 weeks over promised dates

- Inspection time: 45 minutes per part

Our Intelligent Manufacturing Solution:

- Installed wireless vibration sensors on all 5-axis machines

- Implemented real-time thermal compensation software

- Added in-process probing with automatic offset adjustments

- Created digital twins for virtual commissioning of new jobs

- Deployed tool life monitoring with predictive replacement alerts

The Hard Results:

- Scrap rate: Dropped from 15% to 1.2% in 3 months

- Setup time: Reduced from 3.5 hours to 45 minutes

- Inspection time: Cut from 45 minutes to 8 minutes per part

- On-time delivery: Improved from 65% to 98%

- Machine utilization: Increased from 58% to 82%

The client not only got their brackets on time but saved $47,000 in the first year through reduced scrap and faster turnaround. The key was catching problems before they became rejects.

3. Intelligent manufacturing technology to improve CNC machining

Intelligent manufacturing technology for CNC machining has brought significant improvements, specifically in the following aspects:

Automation and robotics

Automated production lines and robots can replace manual labor to complete highly repetitive and labor-intensive work, improve production efficiency and reduce human error.

Data-driven precision control

Through sensors and real-time monitoring systems, CNC machine tools can continuously monitor the parameters of the machining process to ensure machining accuracy and avoid errors.

Artificial Intelligence and Machine Learning

AI technology can analyze and process big data in production, make failure predictions, optimize machining paths, and improve the intelligence of the production process.

The integration of these technologies makes CNC machining no longer rely solely on manual experience, but rather on automated decision-making and optimization through the system, which improves precision and efficiency.

4. How intelligent manufacturing improves the efficiency and precision of CNC machining?

Intelligent manufacturing greatly enhances CNC machining’s efficiency and accuracy in the following ways:

Increased Productivity

Automation reduces downtime and idle time, speeding up production and shortening cycle times for smoother operations.

Enhanced Accuracy

Real-time monitoring and precise control ensure optimal performance, maintaining consistent quality and precision throughout the machining process.

Reduced Human Error

By minimizing reliance on operator skill, intelligent manufacturing lowers the risk of human error, improving the overall stability and reliability of production.

With these advancements, smart manufacturing enables CNC machining to achieve greater precision and efficiency in less time.

5. The impact of intelligent manufacturing on the CNC machining industry chain

The introduction of intelligent manufacturing not only improves the ability of individual processing links, but also has a profound impact on the entire CNC machining industry chain:

Supply chain optimization

Intelligent manufacturing makes the production plan more flexible, enabling immediate adjustment according to market demand and optimizing supply chain management.

Flexible production

CNC machining and intelligent manufacturing together enable quick responses to customer customization, supporting personalized and small-batch production.

Cost reduction

Through lean production and data analysis, intelligent manufacturing helps enterprises reduce production costs, inventory and resource waste.

These impacts make the entire CNC machining industry chain more efficient and resilient, able to respond to increasingly complex market demands.

6. Future outlook

In the future, CNC machining and smart manufacturing will lead to more automated and intelligent production.

With 5G, IoT, and AI, processes will become faster and more efficient, allowing for unmanned operation and real-time optimizations. This will also make it easier for CNC machining to customize products and support small-batch production, driving innovation and smarter manufacturing.

7. Conclusion

Intelligent manufacturing is reshaping the future of CNC machining. By integrating automation, AI, and data analytics, CNC machining is becoming faster, more precise, and more flexible.

As technology continues to advance, intelligent manufacturing will make CNC machining even more automated, boosting efficiency and competitiveness in the industry.