Last updated on 7 January 2026 by Lucy

Poor surface finishes often lead to rejected parts, visible defects, and customer complaints. Many teams underestimate how much surface treatment affects perceived quality and function.

A bead blast finish is a controlled surface treatment that creates a uniform, matte texture while preserving part dimensions, making it ideal for high-quality CNC machined components.

I have machined parts for more than twenty years, and I have seen many good designs fail at the surface finish stage. That is why bead blasting deserves careful explanation, not quick assumptions.

What Is Bead Blasting and How Does the Process Work?

In many projects, surface finish is decided late, which creates confusion and rework. Without a clear understanding of bead blasting, teams risk choosing the wrong process.

Bead blasting is a surface finishing method that uses fine media to clean and texture a part evenly without removing significant material or changing critical dimensions.

I usually explain bead blasting by breaking it into definition, process flow, and media behavior.

What Is Bead Blasting?

Bead blasting uses small spherical media, often glass beads, propelled by compressed air. The beads strike the surface and gently peen it. This removes minor tool marks, oxidation, and handling stains. The process does not cut like grinding. It refines the surface instead.

How the Bead Blasting Process Works

The operator controls air pressure, nozzle distance, angle, and dwell time. Lower pressure keeps edges sharp. Higher pressure increases texture depth. In my shop, we adjust parameters based on material hardness1 and tolerance limits.

Common Bead Blasting Media and Their Characteristics

Different media produce different results.

| Media Type | Typical Use | Surface Effect |

|---|---|---|

| Glass beads2 | Aluminum, stainless steel | Smooth, matte |

| Ceramic beads3 | Hardened steel | More uniform texture |

| Plastic media | Soft alloys, plastics | Very mild cleaning |

Choosing the right media decides both appearance and part safety.

How to Select Bead Blasting Media and When to Use This Finish?

Many engineers ask for bead blasting because it “looks good,” but that alone is not enough. The finish must match function and tolerance.

Media selection and timing define whether bead blasting improves part quality or introduces risk to fit and performance.

I guide customers through material behavior and real use conditions before confirming this finish.

Media Selection for Aluminum, Steel, Stainless Steel, and Plastics

Aluminum benefits from fine glass beads at low pressure. Steel often needs ceramic beads to achieve uniformity. Stainless steel needs clean media to avoid contamination. Plastics require plastic media to avoid surface damage.

Surface Requirements and Functional Considerations

Bead blasting hides fingerprints and small scratches. It also reduces glare. However, it slightly increases surface area, which can affect sealing or sliding fits. I always review mating features before approval.

When Bead Blast Finish Makes Sense — and When It Doesn’t

Bead blasting works well for visible housings, brackets, and covers. It is not ideal for bearing seats, sealing grooves, or press-fit areas. Masking is often required.

What Are the Properties of a Bead Blast Surface Finish?

A bead blast surface is not only visual. It has measurable physical traits that affect performance.

A bead blast finish produces a controlled matte texture with consistent roughness that balances appearance, touch, and functional stability.

In my experience, understanding these properties prevents many downstream issues.

Surface Roughness and Texture

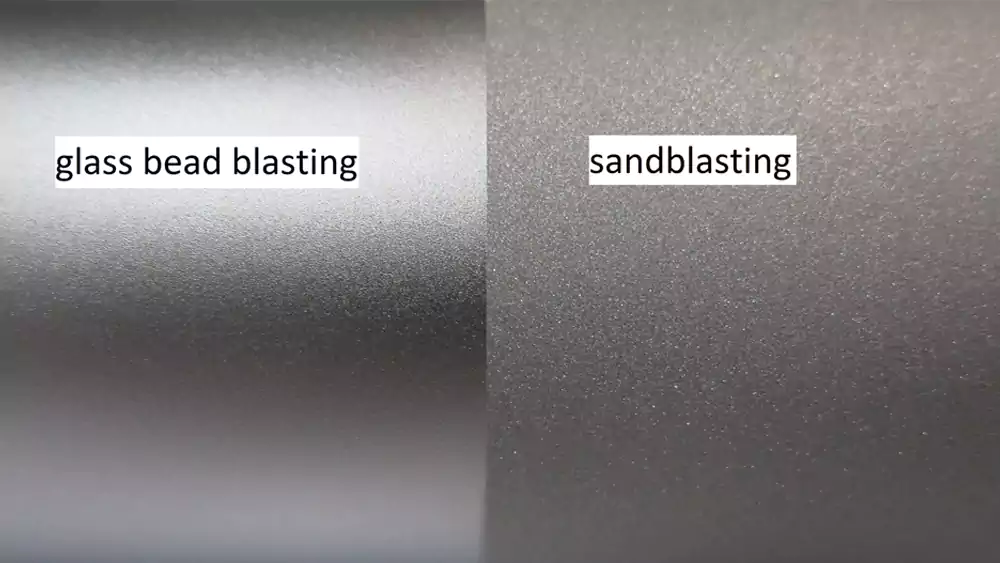

Typical roughness ranges from Ra 1.6 to 3.2 µm, depending on media and pressure. This is smoother than sandblasting but rougher than polishing. Consistency across batches matters more than the exact number.

Visual Appearance and Consistency

Bead blasting creates a soft, uniform look. It hides machining marks and minor defects. This is why many customers choose it for premium products.

Impact on Coatings, Anodizing, and Assembly

Bead blasted surfaces improve paint and powder coating adhesion. For anodizing, the finish becomes more even. For assemblies, increased friction can help prevent slip but must be reviewed.

Case Study: Aluminum Housing for Industrial Automation

A European automation customer had visible swirl marks on CNC-milled housings.

| Parameter | Before | After Bead Blasting |

|---|---|---|

| Material | 6061-T6 | 6061-T6 |

| Roughness | Ra 0.8 µm | Ra 2.0 µm |

| Visual defects | Visible | Hidden |

| Dimensional change | — | <0.005 mm |

| Customer feedback | Rejected | Approved |

The part passed inspection without changing the CNC program.

Bead Blasting vs Other Surface Finishing Methods

Many teams compare finishes without understanding their limits. This leads to poor choices.

Bead blasting sits between aggressive cleaning and fine polishing, offering balance rather than extremes.

I explain differences clearly during sourcing discussions.

Bead Blasting vs Sandblasting

Sandblasting uses angular media. It removes material faster and creates rougher surfaces. Bead blasting is gentler and safer for precision parts.

Bead Blasting vs Polishing

Polishing creates shine but shows fingerprints and scratches. Bead blasting hides marks and offers a professional matte look.

Bead Blasting vs Vibratory Finishing

Vibratory finishing suits bulk parts. Bead blasting offers more control for complex geometries and selective areas.

Comparing Industrial Finishes

Different projects need different tools. If you have 10,000 tiny screws, I will put them in a vibratory tumbler. It is cheaper. But if you have a custom-designed robot arm with complex curves, bead blasting is the winner. You can direct the nozzle exactly where you need it. Polishing is great for mirrors, but it is very slow and expensive. Bead blasting gives you 90% of the beauty for 20% of the cost. Here is how they compare:

| Method | Best Use Case | Finish Type | Cost |

|---|---|---|---|

| Bead Blasting | Custom CNC Parts | Satin / Matt | Medium |

| Sandblasting | Heavy De-rusting | Rough / Dull | Low |

| Polishing | Decorative / Mirrors | Reflective / Shiny | High |

| Vibratory | High Volume Bulk | Semi-Gloss | Very Low |

Limitations and Risks of Bead Blasting You Should Know

Every surface finish has limits. Bead blasting is no exception.

Understanding risks helps prevent tolerance loss, contamination, and functional failure.

I share these points openly with customers.

Dimensional Change and Tolerance Risks

Excess pressure can round edges or enlarge holes. Tight-tolerance areas must be masked or excluded.

Media Contamination and Residue

Used media can embed particles into soft metals. Clean media and proper cleaning steps are essential, especially for medical parts.

Parts and Features That Should Not Be Bead Blasted

Bearing seats, threads, and sealing faces often require protection. Ignoring this leads to assembly problems.

How Bead Blasting Is Used in Automotive, Medical, and Industrial CNC Parts

Application defines acceptance. Bead blasting fits many industries when applied with control.

Automotive, medical, and industrial sectors rely on bead blasting for clean appearance and consistent quality.

I see these uses every day.

Automotive and Motorcycle Components

Covers, brackets, and housings benefit from uniform appearance and reduced glare.

Medical Devices and Equipment Parts

Bead blasting prepares surfaces for coating and improves cleanability when done correctly.

Industrial Machinery and Automation Components

Housings and frames gain durability and professional appearance without changing fit.

Conclusion

Bead blasting offers a balanced surface finish when applied with experience, control, and clear design intent, making it a reliable choice for high-quality CNC machined parts.

-

Exploring this link will provide insights into optimizing your processes based on material characteristics. ↩

-

Explore the advantages of glass beads for achieving a smooth, matte finish in various applications. ↩

-

Learn how ceramic beads can create a more uniform texture, enhancing the quality of your finished products. ↩