Table of Contents:

Precision CNC Machining for Automotive Parts: Driving Quality and Innovation

- October 29, 2024

- Tony

- Last updated on October 31, 2025 by Lucy

In my 20+ years running CNC machines for automotive suppliers, I’ve seen how precision machining has become the backbone of modern vehicle manufacturing. From engine blocks to custom brackets, CNC technology delivers the accuracy and consistency that today’s cars demand.

1. Market demand for automotive parts

The automotive components market is experiencing strong growth driven by electric and smart vehicles. Demand for high-performance, lightweight and customized parts is on the rise. CNC machining plays a key role in this market, enabling the accurate and efficient production of complex parts.

2. Why automotive industry relies on CNC Machining

Unmatched Precision for Safety-Critical Components

- Tolerance Matters: We regularly hold ±0.01mm on brake components and engine parts

- Material Versatility: From aluminum housings to stainless steel fasteners

- Batch Consistency: Part 1 matches part 10,000 exactly

Speed to Market

- Rapid Prototyping: Go from CAD to physical part in days, not weeks

- Production Scaling: Seamlessly move from prototype to full production

- Design Flexibility: Last-minute design changes? No problem with CNC

3. CNC machining processing methods.

The following are common CNC machining methods and their characteristics:

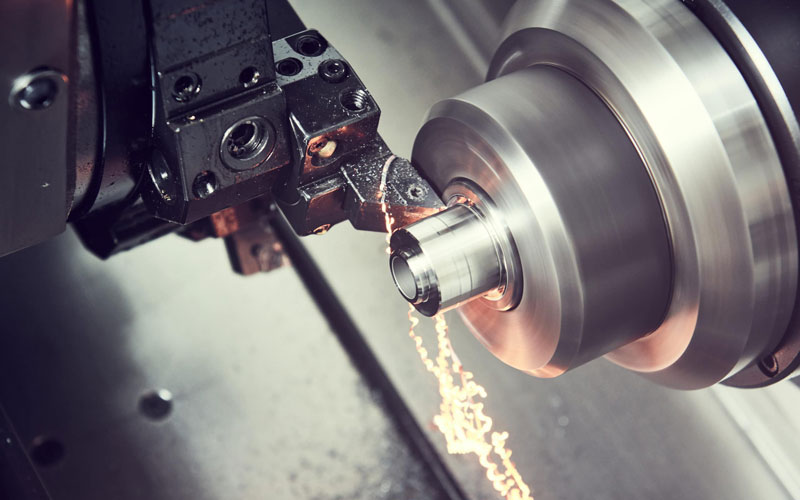

Cnc Turning

CNC Turning is used for machining rotationally symmetrical parts. The workpiece rotates and the tool cuts with high efficiency and precision.

Cnc Milling

It cuts fixed workpieces with rotating tools, capable of machining flat surfaces and complex shapes with high precision.

CNC Grinding

Precision machining with abrasive tools, suitable for improving surface finish. Generally used for surface finishing of precision parts and tools.

CNC Drilling

CNC drilling punches holes in the material by rotating the tool with high precision. It is suitable for hole processing of various materials and widely used in mechanical assembly.

laser Cutting

Laser cutting is widely used for fine cutting of metals, plastics and wood as it is suitable for thin material processing with high precision and fast cutting speed.

EDM

Electrical discharge machining utilizes an electric spark to remove material,can machine hard materials. It‘s used for mold making and complex parts machining.

4. Key automotive applications we specialize in

Component | Machining Method | Material | Description | |

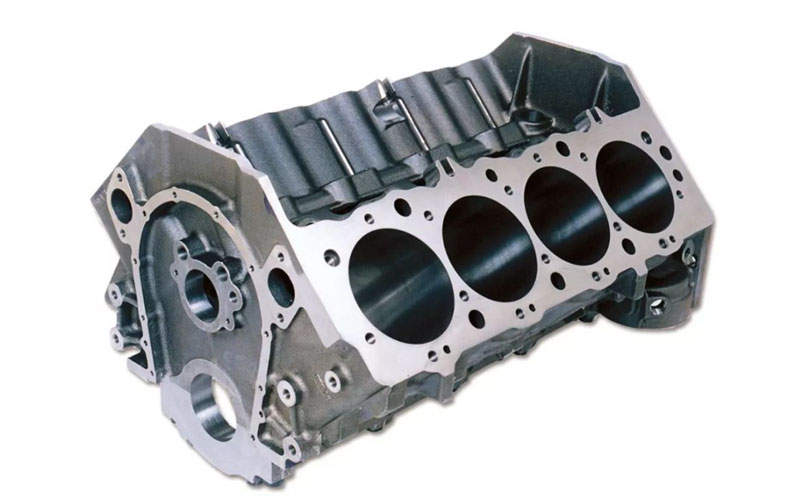

| Engine Block | CNC Milling | Aluminum or Cast Iron | Main structure of the engine, housing the cylinders and combustion chamber. |

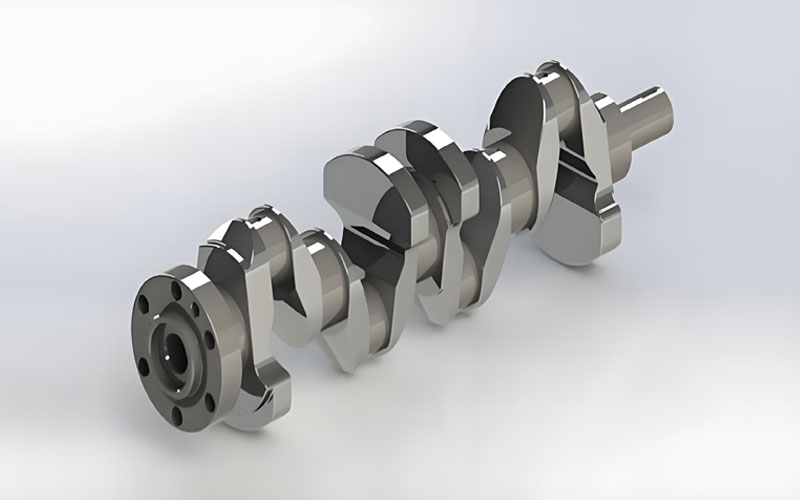

| Crankshaft | CNC Turning | Steel Alloy | Key component converting linear motion of pistons into rotational motion. |

| Drive Shaft | CNC Turning | High-Strength Steel | Transmits power from the engine to the wheels, bearing high loads. |

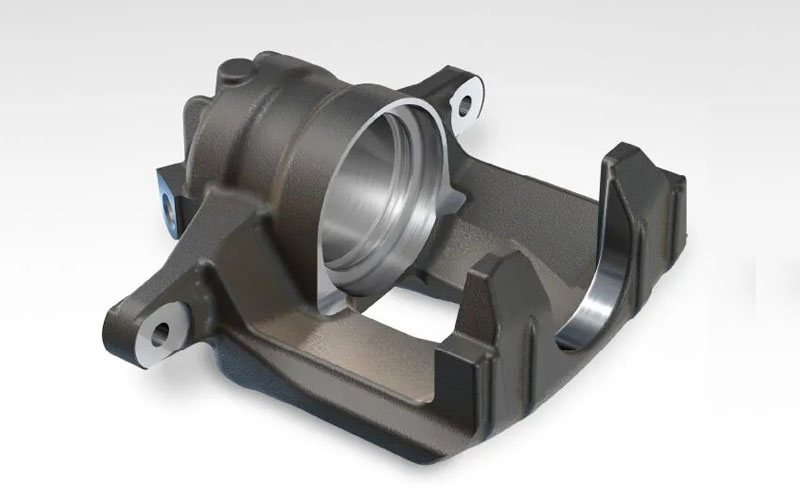

| Brake Caliper | CNC Milling | Aluminum or Cast Iron | Clamps the brake disc to enable braking function. |

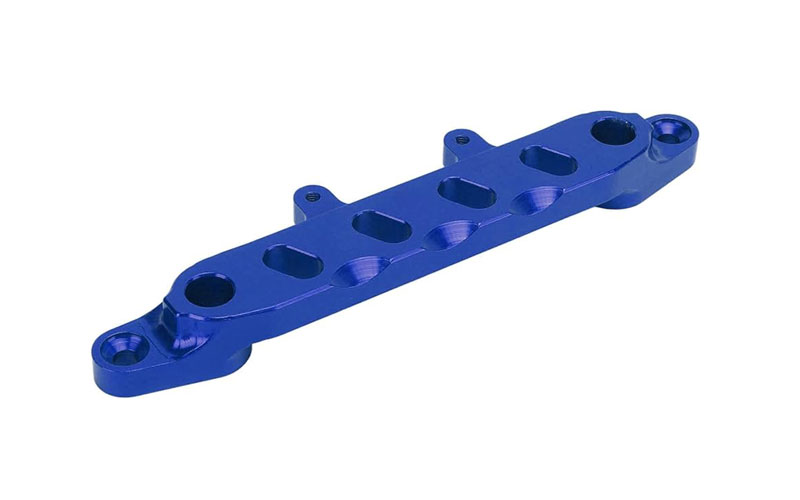

| Body Bracket | CNC Milling | Steel or Aluminum | Provides structural support and stability to the vehicle body. |

| Suspension Arm | CNC Milling and Welding | Steel Alloy | Connects the wheels to the vehicle body, affecting handling and comfort. |

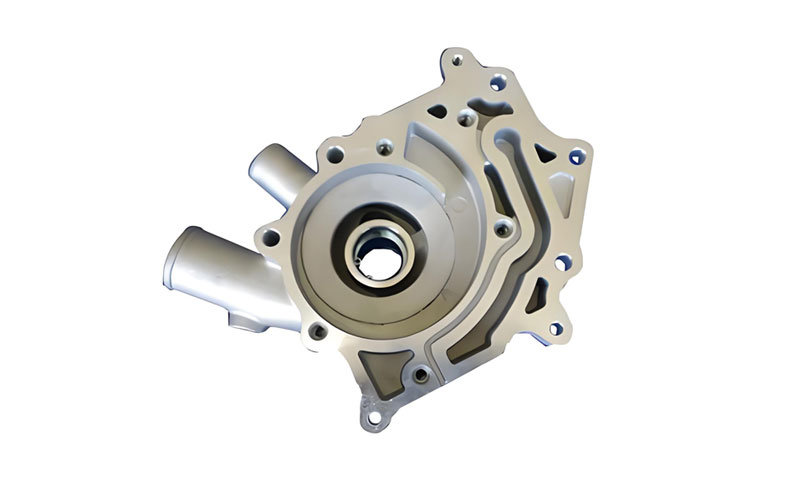

| Oil Pump Housing | CNC Milling | Aluminum | Houses internal components of the oil pump, ensuring oil circulation. |

| Intake Manifold | CNC Milling | Aluminum | Distributes air evenly to the engine cylinders. |

| Battery Housing | CNC Milling | Aluminum or Plastic | Protects battery components and provides good heat dissipation. |

| Oil Pan | CNC Milling | Aluminum or Cast Iron | Stores engine oil, ensuring proper lubrication. |

| Splined-Shaft | CNC Turning | Steel Alloy | Used for transmitting torque between rotating parts, featuring grooves for secure engagement. |

📌Case Study: High-Volume Engine Mount Bracket

The Challenge: A Tier 1 supplier needed 50,000 aluminum engine mount brackets for a new SUV line. The part had complex angles and needed to withstand constant vibration while maintaining precise alignment.

Our Solution: We set up a dedicated production line with 4-axis CNC mills and automated CMM inspection.

Production Details:

- Material: 6061-T6 Aluminum

- Monthly Volume: 12,500 pieces

- Cycle Time: 8.5 minutes per part

- Critical Tolerance: ±0.02mm on mounting holes

- Surface Finish: Anodized for corrosion protection

- Quality: 99.8% first-pass yield rate

- Delivery: Just-in-time scheduling with weekly shipments

The key was optimizing our tool paths to reduce vibration during deep pocket milling. We used custom fixturing that allowed us to machine three sides in one setup, cutting handling time by 60%.

5. Materials We Trust for Automotive Applications

Aluminum Alloys

- 6061-T6: Great all-rounder for brackets and housings

- 7075: When you need extra strength for structural parts

- A380: For complex die-cast components

Steel and Stainless

- 4140: Tough as nails for high-stress components

- 303 & 304 Stainless: Corrosion resistance where it counts

- 1045: Cost-effective for non-critical structural parts

Advanced Materials

- Titanium: For extreme weight savings and strength

- Magnesium: Ultra-lightweight applications

- Engineering Plastics: PEEK, Delrin for specialized needs

6. The Allied Metal advantage for automotive clients

Experience That Shows

We’ve machined everything from classic car restoration parts to cutting-edge EV battery enclosures. That breadth of experience means we can anticipate problems before they happen.

Quality You Can Trust

- First Article Inspection: Every new part gets full dimensional verification

- Statistical Process Control: We monitor production to catch trends before they become problems

- Material Certification: Full traceability on every batch

Partnership Approach

We don’t just make parts—we become an extension of your manufacturing team. When you have a tight deadline or engineering challenge, we’re here to help solve it.

7. Looking ahead: CNC Machining in the EV Era

The shift to electric vehicles is creating new opportunities and challenges. We’re already machining:

- Battery tray components with critical flatness requirements

- Power electronics enclosures with EMI shielding considerations

- Lightweight structural components for range optimization

Summary

CNC machining provides a powerful technology for customizing automotive parts to meet the personalization and performance needs of the modern automotive industry. By choosing the right service company, you can enhance the quality and performance of your parts and give your car a unique appeal.

For more information about CNC machining customized auto parts, please feel free to contact us! Email: quote@alliedcn.com