Selection of suitable tools

- Use high hardness, high wear resistance tools such as carbide or ceramic tools.

- Optimize tool geometries to reduce cut hardening and chip-accumulation tumors.

The Professional CNC Machining Supplier

The Professional CNC Machining Supplier

CNC machining of stainless steel is a manufacturing method that uses CNC machinery and equipment to precisely cut and shape stainless steel materials. Due to its high hardness and machining difficulty, stainless steel plays an important role in CNC machining and is widely used in the manufacture of products that require high strength and corrosion resistance.

Each stainless steel model faces different challenges in CNC machining due to its specific properties. Choosing the right CNC cutting tools, coolant and cutting parameters according to the type and model of stainless steel is the key to ensuring machining efficiency and finished product quality.

Different models (e.g. 304, 316L, 17-4PH) need to adjust cooling methods, tools and parameters accordingly.

Improve the rigidity of the machine tool to reduce vibration and ensure machining accuracy.

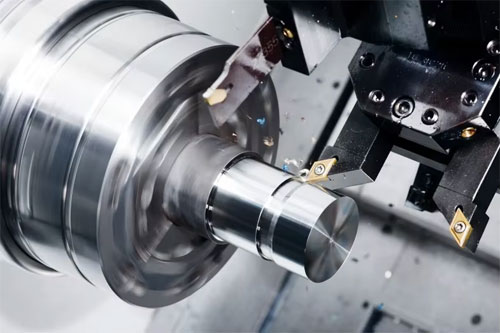

Turning is widely used to machine external rounds, internal holes, and end faces of stainless steel parts. It removes excess material with a cutting tool to shape the part. Proper control of cutting speed, feed, and depth is necessary to prevent overheating and cutting hardening.

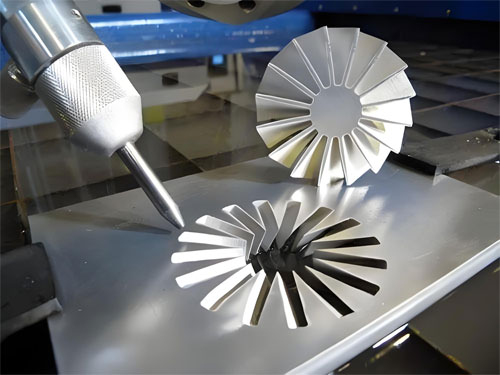

Milling processes flat surfaces, grooves, and beveled edges by removing material with rotary tools. Choosing the right tool material and geometry enhances efficiency and reduces wear. Common milling cutter materials for stainless steel include carbide and coated tools.

Drilling is essential for creating precise holes in stainless steel parts. CNC drilling machines ensure accurate control of hole position, depth, and diameter. Using appropriate speeds and feed rates is important to prevent overheating and tool damage.

Grinding is a high-precision method for refining stainless steel surfaces and removing thin layers of material. Selecting the right grinding wheel with high hardness and wear resistance ensures effective results.

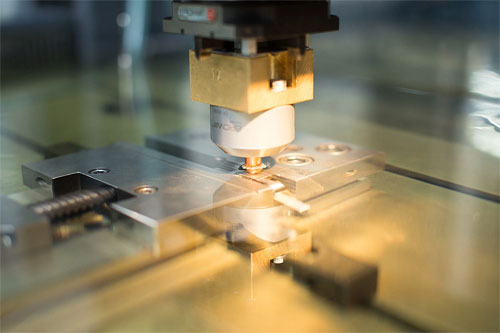

EDM removes stainless steel material through electrical discharges between an electrode and the workpiece. It’s ideal for machining complex shapes or hard-to-cut stainless steel, offering high precision and excellent surface finish.

Laser cutting quickly processes stainless steel, particularly for complex shapes. A high-energy laser beam melts and removes material. This method offers high precision and speed, making it ideal for cutting thin sheet materials.

Waterjet cutting uses high-pressure water to cut stainless steel without heat, preventing material deformation or hardening. It is suitable for cutting complex shapes and thick materials.

Laser marking etches text, patterns, or numbers onto stainless steel surfaces by vaporizing or oxidizing the material. It ensures precise, permanent marks that won’t wear off.

After CNC machining stainless steel, surface imperfections can be removed by polishing to make it smooth and bright, enhancing the appearance and corrosion resistance. Commonly used in decorative parts and high-end equipment shells.

Brushed treatment creates a fine texture on the surface of stainless steel, which not only increases aesthetics, but also improves corrosion and abrasion resistance, and is widely used in the home appliance and automotive industries.

After CNC machining stainless steel, it can be covered with a metal film by electroplating to improve corrosion resistance and appearance, commonly used in electronic products and automotive parts.

Sandblasting removes surface dirt through high-speed jetting of sand particles, increases surface roughness, and improves coating adhesion and corrosion resistance. It is suitable for industrial equipment and construction materials.

Phosphating treatment generates a phosphate film on the surface of stainless steel through a chemical reaction to enhance corrosion resistance, applicable to machine parts and automobile parts.

Nitriding treatment improves the hardness and wear resistance of stainless steel and is suitable for parts that require high strength after CNC machining, such as cutting tools and bearings.

Coating treatment improves the corrosion resistance and aesthetics of stainless steel by covering it with a protective coating. Commonly used in the construction, aerospace and automotive industries.

After CNC machining of stainless steel, pickling removes oxides and dirt, restores metallic luster, and enhances corrosion resistance, especially for cleaning after welding or machining.

CNC machining of stainless steel is widely used in the automotive industry, especially in the production of high-strength components, such as engine parts, exhaust systems, and structural body parts.

Due to its excellent corrosion resistance and high strength, stainless steel is commonly used in the manufacture of automotive parts to ensure the reliability and durability of vehicles in harsh environments.

In the aerospace sector, CNC machined stainless steel is used to manufacture critical components such as aircraft structural parts, engine parts and fuel systems.

The strength, corrosion resistance and good high temperature performance of stainless steel materials make them one of the preferred materials for aerospace applications.

CNC machined stainless steel has a wide range of applications in the medical industry, especially in the production of medical devices and implants. For example, surgical instruments, artificial joints, and dental implants are CNC machined from stainless steel.

The biocompatibility, antimicrobial properties and corrosion resistance of stainless steel materials make them ideal for use in the manufacture of medical devices.

In the electronics industry, stainless steel is commonly used in CNC machining for the manufacture of electronic product housings, connectors and other precision parts.

Its good mechanical properties and corrosion resistance, make stainless steel can effectively protect the internal electronic components to extend the service life of the product.

Stainless steel is widely used in the chemical and energy industries to produce equipment such as reactors, piping, valves and pumps.

CNC machining can ensure that these zero stainless steel parts of high precision and high temperature resistance, corrosion resistance, to meet the chemical and energy industry in the harsh working environment of the high requirements.

CNC machining stainless steel is widely used in shipbuilding, especially in seawater contact parts, such as hull structural components, pipelines and marine equipment.

Corrosion-resistant stainless steel is able to meet the challenges of the marine environment and ensure the safety and durability of ships.

Professional CNC machining services ensure high accuracy and quality, meeting tight tolerances. With advanced equipment and technology, specialized companies can handle various materials and complex designs, boosting efficiency, reducing waste, and lowering costs. Custom services and technical support also guarantee timely delivery and optimal results.

When choosing a CNC machining provider, evaluate their technical capabilities and equipment to ensure they can handle complex tasks. Check their industry experience and customer feedback for consistent quality and on-time delivery.

Trusted providers like Allied Metal, with extensive experience and advanced technology, offer high-quality, customized services at competitive prices, along with after-sales support.

Stainless steel CNC machining is an integral part of modern industry. By mastering the processing skills, choosing the right materials and equipment, it can effectively respond to the processing challenges and broaden the application areas. In the future, with the popularization of intelligent manufacturing technology, stainless steel CNC machining will usher in more innovation and development opportunities.

We use cookies to ensure that we provide you with the best possible experience on our website.