CNC Tool Path Optimization

Basic Principles, Path Parameters and Practical Application Analysis

- March 13, 2025

- Tony

- Last updated on October 24, 2025 by Lucy

1. Overview

What Is a CNC Tool Path?

A CNC tool path refers to the programmed trajectory a cutting tool follows during the machining process. Proper path planning enhances efficiency, minimizes tool wear, and ensures high-precision part machining.

The Importance of Tool Path Planning

Optimizing the tool path is essential for CNC machining. Well-planned paths reduce machining time, minimize material waste, maximize equipment utilization, and lower overall production costs.

How Are Tool Paths Integrated into CNC Machining?

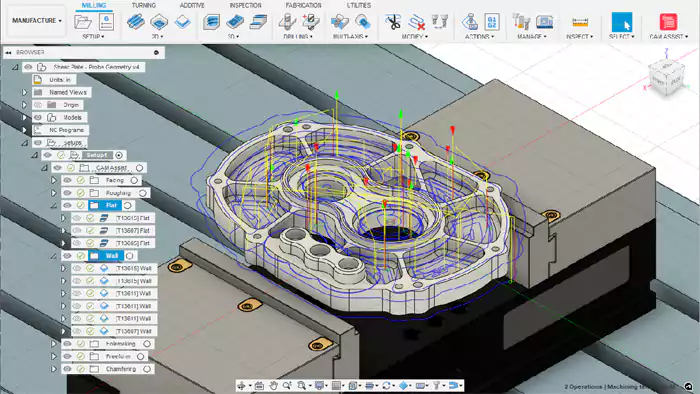

Tool path planning is typically managed through Computer-Aided Manufacturing (CAM) software, which leverages intelligent algorithms to optimize machining strategies and integrate them seamlessly with CNC machine control systems.

2. What are the common tool paths used in CNC machining?

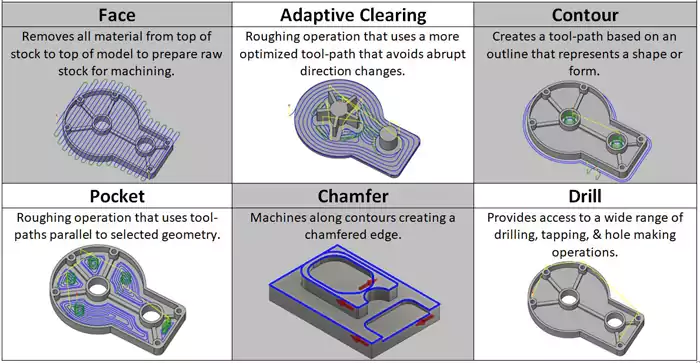

Common tool paths in CNC machining include contouring, drilling paths, helical interpolation, planar milling, surface machining, and so on. Different machining modes require different path strategies to ensure machining accuracy and efficiency.

3. What are the important parameters of CNC tool path?

The key parameters affecting the CNC tool path include feed rate, depth of cut, spindle speed, tool type, and cutting direction. Optimization of these parameters is critical to improve machining quality and extend tool life.

4. How do you choose the right toolpath for your part machining?

Picking the right toolpath isn’t about finding a magic button in the software. It’s a strategic decision based on your part, your material, and your bottom line. Get it wrong, and you’re burning money in tool wear and machine time. Get it right, and you’ve got a reliable, profitable process.

Here’s the way we break it down in our shop:

1. Start with the Geometry: It's All About the Shape

- Simple pockets & 2D contours? Offset or Zig-Zag paths often get the job done fast and clean. There’s no need to overcomplicate it.

- Deep pockets or hard materials? This is where trochoidal or adaptive clearing shines. The tool moves in smooth, circular motions, maintaining a constant load and letting the tool cool as it moves. This isn’t just a fancy feature—it’s a game-changer for tool life in demanding CNC machining services.

- Complex 3D surfaces? You’re in the realm of parallel, spiral, or radial paths. The goal here is all about surface finish. You’re balancing stepover and stepdown to minimize hand-finishing later.

2. Consider the Material: One Size Does NOT Fit All

- Aluminum (soft, gummy): You can be aggressive, but you need to evacuate chips. High-speed toolpaths with high feed rates are your friend to avoid recutting chips.

- Stainless Steel or Titanium (tough, work-hardening): This is where the “rough it and finish it” mentality will cost you. You need toolpaths that reduce heat and constant engagement. A professional CNC machining solution will use strategies that “sneak up” on the final dimensions, leaving a consistent stock for finishing without hardening the material first.

3. Don't Forget the Business End: Time vs. Finish

- Roughing: The goal is simple—remove material as fast as possible. Don’t waste time here on a perfect finish.

- Finishing: This is where you slow down. The goal is dimensional accuracy and surface quality. This is where the right CNC machining service proves its value, using optimized paths that prevent tool deflection and ensure every part meets print.

Honestly, the “best” toolpath is often a combination. We might use adaptive clearing for roughing out a 316L stainless part, switch to a scallop path for the main body, and finish critical sealing surfaces with a spiral pattern.

If you’re not sure, that’s the entire point of partnering with an expert CNC machining solution. Don’t just send out a CAD file and hope for the best. Ask your supplier how they plan to machine your part. Their answer will tell you everything you need to know about their expertise. A true partner will explain their toolpath strategy and how it’s tailored to save you time, money, and headaches.

5. CNC tool path optimization of the basic principles

Optimization Objectives and Key Indicators

The primary goals of tool path optimization include reducing non-cutting time, improving surface quality, extending tool life, and minimizing overall machining costs.

Introduction to Common Optimization Algorithms

Popular path optimization techniques include genetic algorithms, particle swarm optimization, and simulated annealing. These algorithms autonomously determine the most efficient paths, enhancing machining efficiency.

Application of Software Tools and Simulation in CNC Tool Path Optimization

Modern CAM software (such as Mastercam, UG NX, and PowerMill) offers powerful path optimization features. Integrated simulation technology helps validate optimized paths, reducing the need for trial cuts and minimizing errors.

Methods for Optimizing CNC Tool Paths to Achieve Efficient CNC Machining

Choosing the Right Tool Path Strategy

- Use climb milling to minimize cutting forces and enhance surface quality.

- Implement spiral or angled entry cuts to prevent vertical plunge impacts.

- Apply constant-engagement strategies like equal-depth milling and dynamic milling for consistent cutting loads.

Reducing Non-Cutting Movements

- Optimize entry and exit paths to minimize unnecessary tool travel.

- Reduce tool changes by arranging machining sequences logically.

- Utilize parallel machining strategies, such as dual-spindle setups, to increase efficiency.

Optimizing Cutting Parameters

- Adjust cutting speed, feed rate, and depth of cut for optimal efficiency.

- Balance cutting loads to extend tool life without compromising performance.

Leveraging Advanced CAM Software for Path Optimization

- Utilize high-speed machining (HSM) algorithms to reduce tool wear.

- Perform path simulations to detect potential collisions and ensure machining safety.

Enhancing Workholding and Clamping Methods

- Use a single setup to complete multiple operations, minimizing errors and reducing setup time.

- Design fixtures to prevent interference with tool movement.

Maintaining Tools and Equipment

- Regularly inspect tool wear and replace or resharpen tools as needed.

- Maintain machine precision to avoid cumulative errors.

- Implement a tool monitoring system to prevent unexpected tool failure.

Implementing these optimization techniques ensures enhanced efficiency and machining quality.

6. Practical application case sharing

From 4.2 Hours to 2.8 Hours: How We Slashed CNC Cycle Times by 33% on Medical Sensor Housings

The Challenge: When Good Parts Go Bad

We got a call from a medical device manufacturer struggling with 316L stainless steel sensor housings. These weren’t your everyday components – they had deep internal pockets with 3:1 depth-to-diameter ratios, tight 2mm corner radii, and critical sealing surfaces that couldn’t tolerate any tool marks.

The initial production was a nightmare scenario:

- Cycle times bleeding profits: 4.2 hours per part meant they were losing money on every unit

- Tooling costs through the roof: Tools were getting chewed up after just 15 parts

- Surface finish failures: Ra 3.2 μm on critical sealing surfaces led to 8% scrap rate

- Consistent thermal damage: Work hardening from improper tool paths created hardened zones that wrecked subsequent finishing operations

Their existing supplier kept throwing more tools and time at the problem. We knew that approach was like putting bandaids on a broken arm – it might look better temporarily, but the underlying issues would keep causing pain.

The Optimization Process

Before Optimization:

- Cycle time: 4.2 hours per part

- Tool changes: 7 times per part

- Surface roughness: Ra 3.2 μm

- Tool life: 15 parts before replacement

- Material removal rate: 45 cm³/min

- Scrap rate: 8%

Optimized Parameters:

- Switched to trochoidal milling for pocketing operations

- Adjusted stepover from 60% to 35% of tool diameter

- Increased feed rate from 2000 mm/min to 2800 mm/min

- Implemented high-efficiency roughing strategies

- Used corner radius end mills instead of square end mills

- Optimized ramp angles from 3° to 1.5° for hard materials

The Results: Real Numbers from the Shop Floor

After Optimization:

- Cycle time reduced to 2.8 hours (33% improvement)

- Tool changes decreased to 4 times per part

- Surface roughness improved to Ra 1.6 μm

- Tool life extended to 28 parts before replacement

- Material removal rate increased to 68 cm³/min

- Scrap rate dropped to 2%

We took a part that was losing money and turned it into a profitable, reliable production job. The 33% cycle time reduction meant they could run more parts per shift. The improved tool life cut their consumable costs by nearly half. And getting scrap rate down from 8% to 2% eliminated the quality headaches that were keeping their quality manager up at night.

These aren’t theoretical numbers from a software simulation – they’re actual results from a 250-part production run we delivered last month. The client didn’t just get better parts; they got a manufacturing process that actually makes financial sense. If your CNC operations are facing similar challenges where cycle times or tooling costs are eating into your margins, this is exactly the kind of shop-floor optimization we specialize in.

7. Future trends and challenges of CNC tool path optimization

In the future, tool path optimization will rely more on AI and big data analysis, combined with real-time monitoring to achieve adaptive optimization. Despite the continuous progress of CNC machining path optimization technology, it still faces challenges such as high computational complexity and limited flexibility of path adjustment.

8. Summary

CNC tool path optimization is the key to improving machining efficiency and reducing costs. With sound path planning, intelligent optimization algorithms, and advanced software tools, the manufacturing industry can dramatically improve productivity and meet future challenges.