Table of Contents:

Finishing Post-Treatment of Castings: The Key to Enhancing Quality and Performance

- December 20, 2024

- Tony

- Last updated on October 25, 2025 by Lucy

Post-treatment isn’t just a final step—it’s what separates good castings from great ones. As someone who’s been in precision machining for over 20 years, I’ve seen how proper finishing can make or break a part’s performance.

1. What is finishing post-treatment?

Post-treatment refers to processes that enhance the dimensional accuracy, surface quality, and mechanical properties of castings after they are completed. It focuses on improving accuracy, detail, and surface finish, especially for industries with strict quality standards.

Think of it like this: casting gives you the rough shape, but post-treatment turns it into a precision component.

2. Why Finishing Post-treatment for Castings?

Finishing post-treatment ensures castings perform optimally in their final application by improving accuracy, surface quality, and mechanical properties.

Main Benefits of Post-Treatment:

- Improved Accuracy and Stability

Precision machining corrects dimensional errors, ensuring tight tolerances and better fit during assembly. - Enhanced Surface Quality

The process smooths the surface, eliminating defects like roughness, porosity, and sand holes, while improving the overall appearance. - Stronger Mechanical Properties

Treatment boosts hardness, corrosion resistance, and fatigue strength, making castings more durable in harsh conditions and reducing the risk of early failure.

3. Common casting finishing post-treatment methods

The choice of finishing method depends on the material, required accuracy, and functional needs of the casting. Below are some common methods:

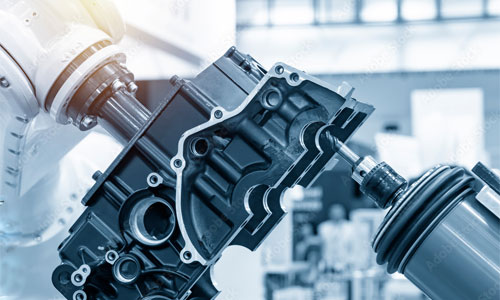

CNC Machining

Precision CNC machining employs computer-controlled processing, making it ideal for high-precision components. This is the perfect choice when you require tight tolerances and complex features.

Grinding and Polishing

Removes small defects and creates smooth, visually appealing surfaces. Great for parts needing higher corrosion resistance.

Electrolytic Polishing

Uses an electrochemical process to improve surface gloss and reduce roughness. Our go-to for stainless steel and aluminum alloys.

Deburring and Cleaning

Deburring removes excess material and sharp edges, ensuring a smooth, safe surface free from burrs and impurities that could cause damage or danger in later use.

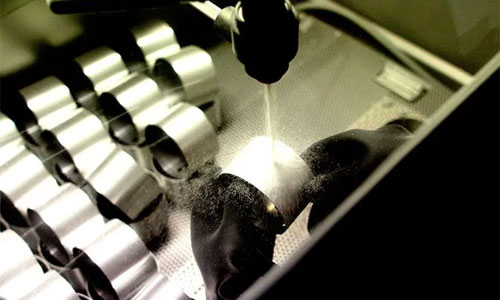

Precision Sandblasting

Precision sandblasting cleans and textures the surface by spraying fine sand, removing oxidation and contaminants. This improves surface appearance and enhances adhesion for coatings or finishes.

4. Impact of finishing post-treatment on casting properties

This is where the magic happens. Proper finishing transforms good castings into high-performance components:

- Improves Accuracy and Fit: CNC machining and defect removal reduce dimensional errors, ensuring precise assembly.

- Better Surface Finish and Corrosion Resistance: Smoothing surfaces reduces micro-cracks and extends component lifespan.

- Enhanced Fatigue Strength and Wear Resistance: Hardening and smoothing surfaces reduces friction and improves resistance to cracking under stress.

✅ CASE STUDY: Aerospace Bracket Finishing

We recently handled an aerospace bracket that came to us with surface roughness issues and dimensional variations. Here’s how we turned it around:

Initial Condition:

- Material: Aluminum 7075

- Surface roughness: Ra 3.2 μm (as-cast)

- Dimensional tolerance: ±0.5mm

- Required lifespan: 10,000+ cycles under vibration

Post-Treatment Process:

- CNC machining to achieve ±0.05mm tolerance

- Precision grinding to reduce surface roughness to Ra 0.8 μm

- Electropolishing for corrosion resistance

- Micro-shot peening for fatigue strength improvement

Final Results:

- Surface roughness improved to Ra 0.4 μm

- Dimensional accuracy within ±0.03mm

- Passed salt spray test for 500+ hours

- Fatigue life increased by 40% compared to unfinished parts

The client reported zero field failures after 18 months of service. This kind of transformation is why we always recommend investing in proper post-treatment—it pays for itself in reduced downtime and longer component life.

At Allied Metal, we specialize in these kinds of precision transformations. Our team has the expertise to recommend the right combination of processes for your specific application.

5. Industry Applications of Finishing Post-treatment

Different industries, different needs—but one common truth: finishing matters.

Automotive

Extremely high dimensional accuracy and surface finish requirements. Quality finishing ensures long-term durability and safety.

Medical equipment

Precise dimensions plus strict hygiene and corrosion resistance standards. Post-processed medical castings meet industry specifications.

High-end machinery and molds

Accuracy directly affects productivity and product quality. Post-treated castings deliver optimal performance.

6. Synergies between casting finishing and other manufacturing processes

Finishing post-processing not only works independently, but also in close collaboration with other manufacturing processes to ensure that castings are optimized.

Cooperation between reprocessing and casting processes

Finishing post-processing of castings is closely integrated with the casting process. Casting provides the initial shape for post-processing, while finishing builds on this to further improve accuracy and quality.

Finishing post-treatment with heat treatment and surface treatment

Heat treatment and surface treatment improve the internal structure and surface properties of the casting, while finishing focuses on the appearance and dimensional details, ensuring excellent overall performance through the synergy of all three.

7. Choose Allied Metal for your precision machining needs!

With two in-house facilities and a strong supply chain, we use advanced equipment and expertise to ensure every casting meets high standards of precision and quality.

Whether you need complex CNC machining, fine surface finishes, or performance enhancements, we offer customized solutions to support your project. Plus, our reliable after-sales service and timely shipping ensure a smooth and efficient experience.

Here’s what sets us apart:

- 20+ years of precision machining experience

- In-house CNC, grinding, and polishing capabilities

- Material expertise across metals and alloys

- Quick turnaround times without compromising quality

We’ve helped hundreds of engineers and procurement managers solve their trickiest casting challenges. Let us help you get parts that not only meet specs but exceed expectations.