Table of Contents:

The Complete Guide to CNC Machining Plastics

- December 9, 2024

- Tony

1. Overview

1.1 What are CNC machining plastics?

CNC machining plastics is the process of using CNC technology to precisely machine plastic materials. By following pre-programmed instructions, the CNC system controls the machine and tools to achieve high precision, automating complex tasks and ensuring consistent quality in plastic parts.

1.2 Why choose CNC machining plastics?

Choosing CNC to machine plastic workpieces has the following advantages:

- High Precision & Consistency

CNC machining delivers high accuracy, ensuring consistent dimensions and minimizing errors. - Complex Shape Capability

Easily processes intricate plastic parts to meet diverse design needs. - Increased Productivity

CNC machines work continuously, speeding up production and lowering costs. - Reduced Material Waste

Precise cutting minimizes waste and optimizes cost efficiency. - Versatile Material Handling

CNC machining works with both thermoplastic and thermoset plastics. - Fast Prototyping & Customization

Quickly creates functional prototypes, reducing design cycles and meeting customization needs. - Minimal Post-Processing

Produces smooth surfaces, reducing the need for sanding or finishing. - Adaptability to Changes

Easily adjusts to design modifications without retooling molds, saving time and money. - Automated Mass Production

Supports efficient, automated production with consistent quality.

1.3 Common Machines for CNC Machining Plastic Parts

The following types of machines are commonly used when CNC machining plastics:

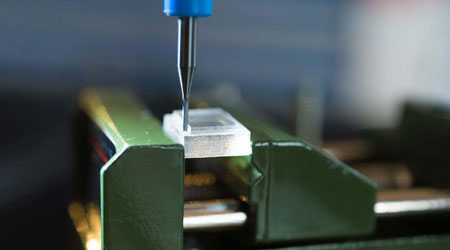

Suitable for most plastics processing, capable of precision cutting, engraving and removing excess material.

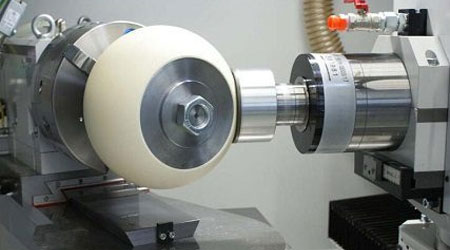

Used for machining round or symmetrical plastic parts, capable of providing highly accurate rotational machining.

For fine cutting of thin plastic sheets, especially for patterns or fine parts.

For precision machining, capable of achieving higher surface finish requirements.

2. What are the common types of plastics that are CNC machined?

In addition to being easy to machine, plastics have the advantage of high efficiency, high precision and wide applicability in CNC machining projects. Common plastic materials used for CNC machining are as follows:

Polycarbonate (PC)

With extremely high impact resistance and transparency, it is commonly used in optics, aviation and other fields.

Polyoxymethylene (POM)

Widely used in parts such as gears and bearings due to its excellent mechanical properties and low friction characteristics.

Polyethylene (PE)

A lightweight, chemically resistant plastic commonly used in containers and piping systems.

Polypropylene (PP)

Has good heat resistance and chemical stability and is commonly used for automotive and appliance parts.

Polyvinyl chloride (PVC)

Widely used in plumbing and electrical fittings.

Nylon (PA)

With good strength and abrasion resistance, commonly used in engineering machinery and automobile parts.

3. What are the common CNC machining plastic processes?

Removal of plastic material by rotating cutting tools enables the creation of complex shapes and high-precision surfaces. Commonly used for machining mold cavities, cores, slides and other parts.

By rotating the lathe and feeding movement of the tool, it completes the machining of outer circle, inner hole, thread and so on. It is suitable for round or symmetrical shaped plastic parts, such as shafts.

Used for machining holes in plastic parts, widely used in the production of electronic components and connectors.

Plastic parts are finished by grinding machine to improve the surface quality and accuracy of the parts.

As a non-contact processing method, laser cutting is suitable for plastic parts of various shapes. It allows for fast, precise cutting and is ideal for thin sheet materials.

For complex shapes that are difficult to machine by milling, such as fine sharp corners. Especially suitable for machining hard materials by eroding the metal by EDM.

4. CNC machining plastics and injection molding processing which is better?

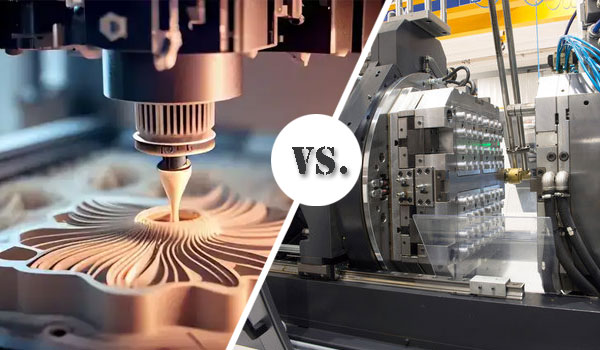

CNC machining and injection molding are two common plastic processing methods, each with its own pros and cons:

- CNC Machining:

Best for low-volume, high-precision, customized plastic parts. It handles complex shapes and offers flexibility. Ideal for prototyping and small-batch production with quick cycle times. - Injection Molding:

Best for high-volume production, significantly reducing the cost per part. It works well for simple, standardized parts, but requires more expensive molds and longer lead times.

Generally, trade-offs can be made between speed/quantity, cost, and materials. CNC machining is ideal for small batches, complex designs, and high-precision parts, while injection molding is more cost-effective for large-scale production.

5. 4 Tips for CNC machining plastics

Mastering these 4 skills can significantly enhance both the quality and efficiency of CNC machining plastics:

- Choose the Right Tool:

Different plastics have unique cutting properties. Selecting the appropriate tool material and shape helps improve machining efficiency and part quality. - Control Cutting Speed:

Excessive cutting speed can cause melting or deformation of plastics. Controlling the speed ensures better results and avoids such issues. - Use Coolants:

For certain plastics, using coolants helps reduce heat buildup and prevents material deformation. - Monitor Tool Wear:

Regularly check for tool wear and replace worn tools promptly to maintain machining accuracy.

6. CNC machining plastics optimal cutting parameters selection method

Choosing the right cutting parameters is crucial for improving the quality and efficiency of CNC machining plastics. Here are the key parameters and recommendations:

1. Cutting Speedading for CNC machining plastics

Cutting speed affects the machining outcome. For rigid plastics, higher cutting speeds improve efficiency. For softer plastics, lower speeds are recommended to avoid excessive heat and deformation.

2. Depth of Cut for CNC machining plastics

Depth of cut refers to how much material the tool removes per pass. Shallower cuts improve surface quality and extend tool life. Adjust the depth based on tool stability and longevity.

3. Feed Rate

Feed rate is the speed at which the workpiece moves during cutting. Lower feed rates reduce cutting force and temperature, improving quality, but too low a feed rate can lower efficiency. Balance is key, and adjustments should be made based on the material.

4. Tool Selection

Select the CNC cutting tools with good wear resistance and cutting rigidity. Carbide and polycrystalline diamond tools are commonly used for plastics. Choose the right tool material based on the specific requirements of CNC machining plastic parts.

5. Cutting Fluids

Cutting fluids cool the tool and workpiece, while also clearing chips. Proper use can improve both machining quality and efficiency when working with plastics.

7. Summary (CNC Machining Plastics)

CNC machining of plastics offers efficient and flexible solutions for modern manufacturing, meeting complex design requirements while ensuring high precision and consistency.

By selecting the right material, process, and cutting parameters, high-quality plastic parts can be produced for various industries.

When choosing a CNC machining supplier, ensure they have the experience and advanced equipment to guarantee the quality and performance of the final product.