Editor’s Note: Last updated on November 5, 2025, by Lucy

When you’ve been in this business as long as I have, you learn that CNC machining isn’t about fancy technology – it’s about getting parts made right, fast, and at the right price. Let me walk you through the methods we use daily to make everything from simple brackets to complex aerospace components.

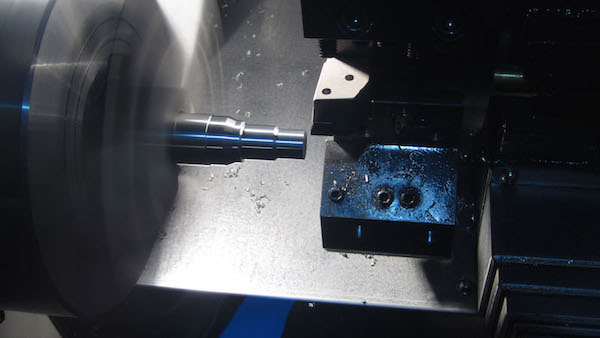

CNC Turning

Turning is what we use when you need anything round. The part spins while our cutting tools shape it. Here’s what really matters:

What we make daily:

- Shafts, bushings, and pins

- Engine components and hydraulic fittings

- Any part that’s symmetrical around an axis

Why it works:

- Fast material removal – we can turn a 2-inch diameter down to 1 inch in one pass

- Excellent surface finish – typically Ra 0.8μm without secondary operations

- Tight tolerances – we regularly hold ±0.01mm on diameters

The reality: If your part is round, turning is almost always your most cost-effective option.

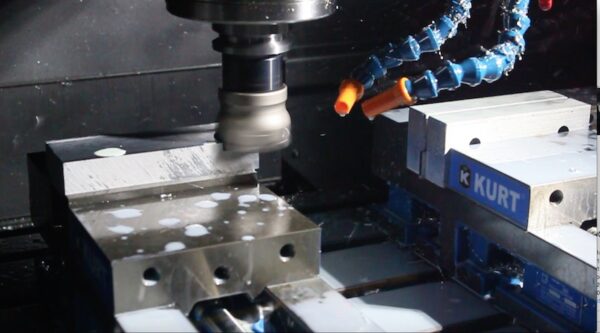

CNC Milling

Milling is our go-to for complex shapes. The tool spins while the workpiece stays put. After 20+ years, here’s what I’ve learned:

3-axis vs 5-axis truth:

- 3-axis: Handles 90% of work perfectly – flat surfaces, pockets, simple contours

- 5-axis: For complex curves and angles that would require multiple setups

What mills do best:

- Complex housings and brackets

- Mold cavities and patterns

- Parts with multiple features on different faces

The Supporting Cast - Other Essential Methods

CNC Drilling - When Holes Matter

CNC Cutting - Precision in Profile

We don’t just cut shapes – we create exact profiles ready for assembly. The difference between rough cutting and precision cutting comes down to:

- Edge quality that eliminates secondary finishing operations

- Thermal control that prevents material distortion in thin sections

- Nesting efficiency that maximizes material utilization from each sheet

CNC Grinding - The Final Touch

When surface finish really matters, grinding delivers. We use it for:

- Bearing surfaces that need Ra 0.2μm or better

- Hardened materials that other tools can’t handle

- Critical dimensions where ±0.005mm matters

EDM - The Shape Creator

When conventional cutting can’t handle the geometry, EDM delivers. We use it for:

- Complex internal features in hardened tool steels up to 62 HRC

- Sharp internal corners with radii under 0.1mm that mills can’t produce

- Delicate components where cutting force would cause distortion

Wire EDM - The Through-Cut Specialist

When you need perfect profiles through thick materials, wire EDM excels. Our applications include:

- Cutting extrusion dies and stamping tools from 150mm thick tool steel

- Prototype gears and splines with ±0.005mm tooth form accuracy

- Medical device components requiring burr-free edges and Ra 0.4μm surfaces

CNC Routing - The Large Format Expert

When part size exceeds standard machine capacity, routing takes over. We rely on it for:

- Composite aerospace panels up to 3×6 meters with complex cutouts

- Pattern making where wood and plastic replace metal for prototyping

- Aluminum composite material (ACM) signage with engraved details and clean edges

CNC Bending - The 3D Former

We don’t just bend metal – we create precise 3D geometries from flat patterns. Success depends on:

- Springback compensation that accounts for material memory in different alloys

- Bend sequence planning that avoids tool interference in complex parts

- Surface protection that prevents cosmetic damage on pre-finished materials

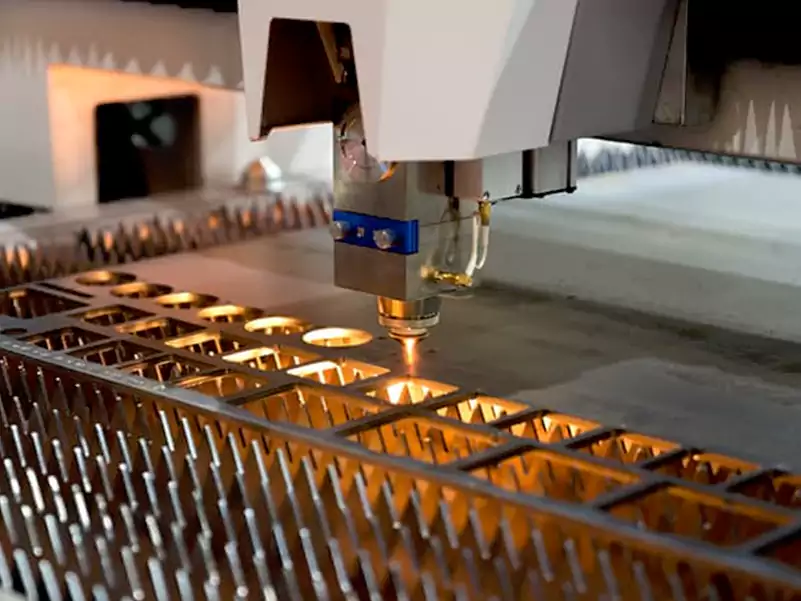

Laser Cutting - For Sheet Metal

Case Study: Automotive Transmission Bracket

The Challenge: A tier-1 automotive supplier needed 5,000 transmission mounting brackets in 6 weeks. The part required multiple operations with tight positional tolerances between features.

Our Manufacturing Approach:

- Material: 4140 steel, 25mm thick plate

- Primary Operations:

- Laser cutting: Profile the outer shape from plate stock (±0.15mm)

- CNC milling: Machine mounting pads and complex contours (±0.05mm)

- CNC drilling: 12 precision holes for mounting (±0.025mm position)

- CNC tapping: M8 and M10 threads for fasteners

- Quality Results:

- First article approval in 3 days

- Production rate: 85 pieces per day

- Final inspection: 99.8% of parts within all specifications

- On-time delivery: All 5,000 parts delivered in 5 weeks

The key was running laser cutting and milling operations in parallel, then batching parts for drilling and tapping. This approach cut the estimated production time by 30%.

How to Choose the Right Method?

Start with Your Part Geometry

- Round parts: Start with turning

- Complex shapes: Milling is your friend

- Flat patterns: Consider laser cutting

- High-precision surfaces: Grinding might be needed

Consider Your Quantities

- Prototypes: Milling often makes sense for one-offs

- Production: Turning might be faster for high volumes

- Mass production: Sometimes multiple methods work together

Don't Forget Materials

- Aluminum: Most methods work well

- Stainless steel: Requires more power and better tooling

- Plastics: Watch out for heat and melting

- Exotics: May require specialized approaches

The Truth About Modern CNC Machining

It's Not Just About the Machines

The best equipment in the world won’t help if you don’t have experienced programmers and operators. I’ve seen $500,000 machines produce scrap because the setup was wrong.

Speed vs. Quality

We can make parts fast or we can make them perfect. The art is finding the right balance for your specific needs.

Cost Isn't Just the Piece Price Consider:

- Lead time impact on your project

- Quality consistency

- Engineering support available

- Problem-solving capability

Why Experience Matters?

I’ve made every mistake in the book – and learned how to avoid them. That experience means:

- Knowing when a design won’t machine well

- Understanding how to hold tricky parts

- Recognizing when tolerances are unnecessarily tight

- Finding ways to reduce costs without compromising quality

Conclusion:

Good machining comes down to matching the right method to your part. There’s no one-size-fits-all solution, but with experience, we can usually find the most efficient approach.

The methods haven’t changed much in 20 years, but our ability to implement them efficiently has improved dramatically. What used to take days now takes hours, and the quality is better than ever.

Not sure which machining method is right for your part?

Send us your drawings. We’ll give you the straight story on the best approach for your needs and budget.