Editor’s Note: Last modified on November 7, 2025, by Lucy

What Exactly is 5-Axis Machining?

If you’ve been in manufacturing long enough, you know not all CNC machines are created equal. 5-axis CNC machining is where the real flexibility and precision happen — especially for complex, tight-tolerance parts. Let me break it down in simple terms.

5-axis CNC machining allows a cutting tool to move on five separate axes simultaneously. This enables the machining of extremely complex parts in a single setup (a “one-and-done”), offering incredible precision, speed, and design freedom.

Think of “5-axis” as the machine’s ability to move a part or a tool along five different directions (or axes) at the same time. In addition to the standard three linear axes — X, Y, and Z — the cutting tool or the part can also rotate along two additional rotary axes (typically A and B, or one of them being C). This lets the machine approach the workpiece from virtually any direction without needing to reposition it manually.

That means:

- Fewer setups

- Higher accuracy

- Ability to make incredibly complex geometries in one go

What Is 3+2 Axis Machining?

Okay, first thing you need to know: there are two types of “5-axis.” The first is what we call “3+2” or “indexed” 5-axis.

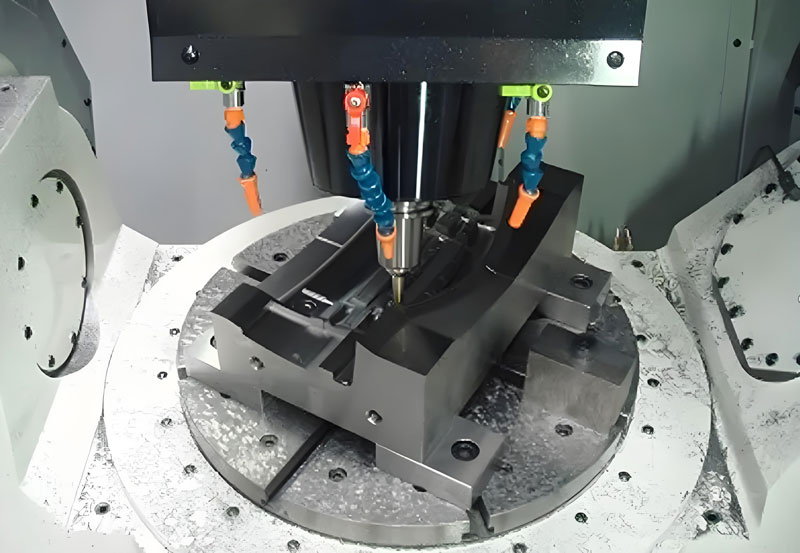

3+2 axis machining is when the machine uses two rotational axes (the 4th and 5th axis) to position the part at a specific angle. Then, it locks the part in place, and a standard 3-axis (X, Y, Z) program runs.

Diving Deeper into 3+2

Think of it this way: the machine does all the “setup” work for you. On a 3-axis machine, if you need to drill a hole at a 45-degree angle, I have to build a custom fixture to hold your part at a 45-degree angle. With 3+2, I just tell the machine to “tilt the part 45 degrees.” The machine does it, locks the table, and then the tool drills the hole, perfectly.

This is fantastic for parts with features on multiple faces, like a housing with holes on all six sides. It’s a huge time-saver and a massive boost for accuracy.

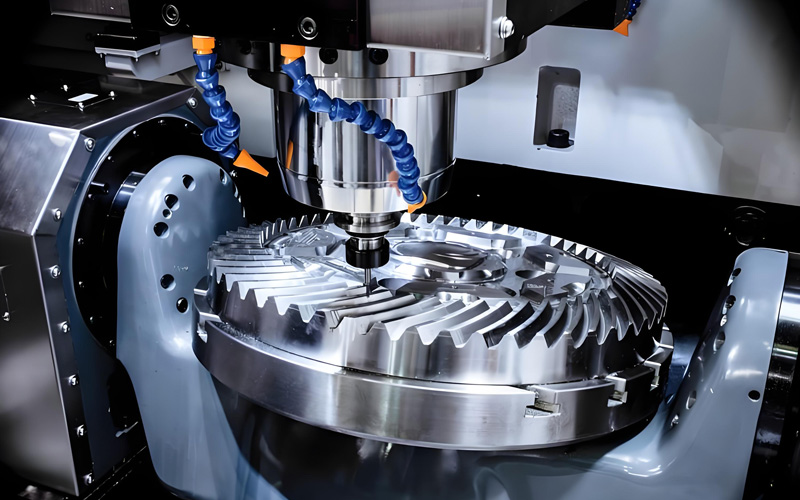

What Is Simultaneous 5-Axis Machining?

This is the real magic. This is what we’re talking about when we machine things like impellers, turbine blades, or medical implants.

Simultaneous 5-axis machining is when the machine’s tool and the workpiece are both moving at the same time, on all five axes. This allows the machine to create smooth, complex, “organic” contours and shapes.

Diving Deeper into Simultaneous 5-Axis

Here, the machine is truly “sculpting” the material. The X, Y, and Z axes are moving, while the A and B axes (the two rotational axes) are constantly tilting and rotating the part. This is the only way to create those beautiful, smooth surfaces on things like a boat propeller or the femoral component of a knee replacement.

The other huge advantage—and this is a “must-know” for engineers—is that it lets us use shorter, more rigid cutting tools. Why? Because the machine can tilt the tool or the part to avoid a collision. On a 3-axis, if you have a deep pocket, I have to use a long, skinny tool that will vibrate, chatter, and leave a terrible surface finish. On a 5-axis, I can tilt the part and get in there with a short, stubby tool that cuts like a dream.

3-Axis vs. 3+2 Axis vs. 5-Axis Machining

Here’s the simple cheat sheet I give to new engineers. This table breaks down what you get with each process.

| Feature | 3-Axis CNC Machining | 3+2 Axis CNC Machining | Simultaneous 5-Axis CNC Machining |

|---|---|---|---|

| Complexity | Simple, 2.5D parts | Moderately complex, angled features | Highly complex, organic shapes |

| Setups | Multiple setups for 6-sided parts | Fewer setups, single setup for 5 sides | Single setup ("One-and-done") |

| Tooling | Requires long tools for deep pockets | Can use shorter, more rigid tools | Can use shortest, most rigid tools |

| Accuracy | Good, but "tolerance stack-up" from multiple setups is a risk | High accuracy, as datums are maintained | Highest possible accuracy |

| Cost | Cheapest for simple parts | More expensive for simple parts, but cheaper for complex parts | Highest machine cost, but can be the lowest total part cost for very complex parts |

What Are the Benefits of 5-Axis CNC Machining?

When a sourcing manager asks me “Why 5-Axis?” I don’t give them a sales pitch, I give them facts. Here’s what it means for your project:

- Single Setup (The “One-and-Done”)

- This is the biggest benefit. We clamp the block of material once and machine the entire part. This eliminates “tolerance stack-up,” which is the error that creeps in every time you manually unclamp and re-clamp a part. It’s the key to achieving the tight geometric tolerances (like True Position) on your drawings.

- Machining Complex Shapes

- You can design it, we can machine it. Organic contours, undercuts, angled ports, turbine blades… 5-axis is what makes these parts possible.

- Higher Accuracy and Quality

- By using shorter, more rigid tools, we get less tool “chatter” and “deflection.” This directly translates to a better surface finish (lower Ra) and parts that are dimensionally perfect, right off the machine.

- Faster Machining & Lead Times

- This one surprises people. “But the machine is so expensive!” Yes, but it’s faster. While the final cut might be slow, we save days of time by eliminating multiple setups and the need to design and build custom fixtures for every single operation.

- Single Setup (The “One-and-Done”)

Case Study: High-Precision Aerospace Bracket

All that theory is nice, but let’s talk about a real part. A client in the aerospace industry came to us for a lightweight structural bracket—a part that anchors a control surface to the main airframe.

The Challenge: The part was machined from a solid billet of 7075-T6 Aluminum. The design was almost all deep pockets—like a skeleton—to save every possible gram of weight. But the real problem was that it had four critical mounting holes on two different, compound angled faces. A 3-axis shop would have needed at least 5 different setups and two custom-built “angle plate” fixtures. The chance of scrapping the part on the last setup was huge.

Key Part Specs & Our "One-and-Done" Solution:

- Part: Aerospace Structural Bracket

- Material: 7075-T6 Aluminum (High strength, but notorious for warping if you don’t know how to machine it).

- Critical Tolerance: The True Position of the four angled mounting holes, relative to the main bearing bore, had to be within Ø 0.05 mm.

- Secondary Tolerance: The bearing bore itself had a diameter tolerance of ±0.01 mm.

The Shop-Floor Truth (How We Did It): We put this on our 5-axis mill. We clamped the part one time.

- We roughed out the deep pockets, “hogging out” material with a high-feed mill.

- Then, the machine—all in the same program—rotated the part to Angle 1 (e.g., 30° tilt, 15° rotation) and drilled/bored the first two holes.

- Without stopping, it rotated to Angle 2 (e.g., 90° tilt, 45° rotation) and finished the other two holes.

- Finally, it came back to the main bore and ran a finishing pass to hit that tight ±0.01 mm tolerance.

The Result: We delivered a part that was 100% in spec. The 3-axis shop couldn’t guarantee the relationship between the holes. We could. By machining all critical features in one setup, we eliminated the “stack-up” error. The client got a lighter, stronger, and more reliable part, and we delivered it in 3 weeks instead of the 6 weeks they were quoted for the multi-fixture process. That’s what 5-axis does.

Applications of 5-Axis CNC Machining

You can see why 5-axis is the standard for any industry where precision and complexity are non-negotiable. We use it every day for parts in:

- Aerospace: Turbine blades, impellers, structural components, and actuator housings.

- Medical: Orthopedic implants (like knee and hip joints), spinal fusion cages, and surgical instruments.

- Automotive: Engine blocks, cylinder heads, high-performance suspension components, and prototyping.

- Defense: Optics, guidance systems, and lightweight components.

- Oil & Gas: Complex valve bodies and down-hole sensor components.

When Should You Choose 5-Axis Machining?

Here’s my rule of thumb:

- Your part has complex geometry or multiple sided features.

- You’re holding tight tolerances (below ±0.1 mm).

- You want to reduce part handling and speed up production.

- You’re working with expensive material and want to minimize scrap.

Summary:

5-axis CNC machining is far from being an empty buzzword—it represents a practical CNC solution for efficiently manufacturing precision parts. Not only does it enhance machining speed and accuracy, but it also delivers a more cost-effective solution when considering the total cost of multiple setups and secondary operations.

Looking for a reliable 5-axis machining partner?

Got a challenging part? Send us your drawings. Let’s see if 5-axis is the right fit for you.