Metal parts machining

Metal parts machining specialists!

AlliedMetal is familiar with a wide range of metal working materials!

- Source Factory

- Reasonable price

- Certified Materials

- Timely delivery

Common Metalworking Materials

NAME | Brief Characteristics | Application Areas | |

High strength, wear-resistant, good shock absorption, suitable for complex parts. | Engineering machinery, automotive engine parts | ||

Lightweight, corrosion-resistant, excellent conductivity and thermal performance, widely used in lightweight designs. | Aerospace, automotive, consumer electronics | ||

High strength, hardness, and wear resistance, ideal for high-load parts. | Construction, automotive, industrial equipment | ||

Corrosion-resistant, oxidation-resistant, high strength, suitable for high-corrosion-resistant parts. | Medical devices, food processing equipment | ||

Excellent conductivity and thermal performance, corrosion-resistant, easy to machine. | Electrical equipment, plumbing systems, decorative items | ||

Lightweight, high strength, corrosion-resistant, ideal for high-strength and weight-sensitive applications. | Aerospace, medical devices | ||

The world's lightest structural metal, with good electromagnetic shielding and recyclability. | Automotive, aerospace, electronic devices | ||

High melting point, excellent conductivity, resistant to high-temperature oxidation. | Aerospace, high-temperature equipment parts |

How to choose the right metal material for machining

Choosing the right metal for CNC machining is crucial for success. Several factors need to be considered, such as:

- Temperature Resistance: Ensure the metal can withstand high temperatures.

- Strength: It should not bend or break under pressure.

- Corrosion Resistance: Protects against rust and wear.

- Workability: Affects how easily the metal can be shaped and processed.

- Cost: Consider your budget.

- Weight: Important for overall design and application.

- Appearance: The visual appeal of the final product.

Choosing the right metal for the job ensures that your project meets performance and quality standards while saving time and money.

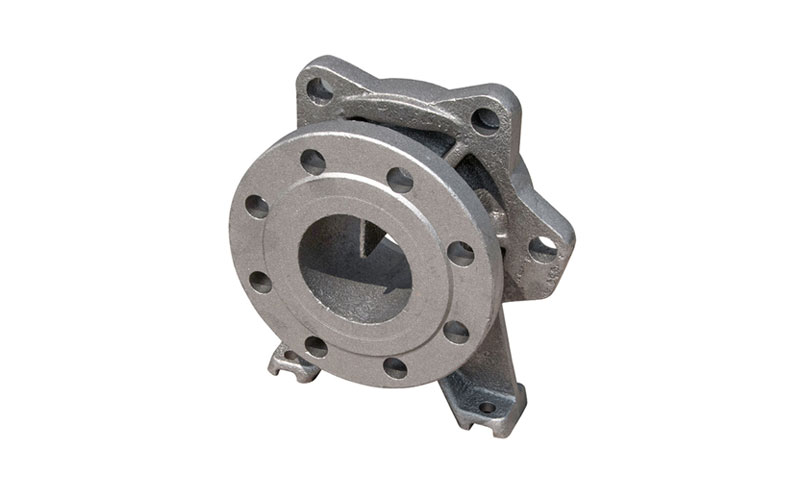

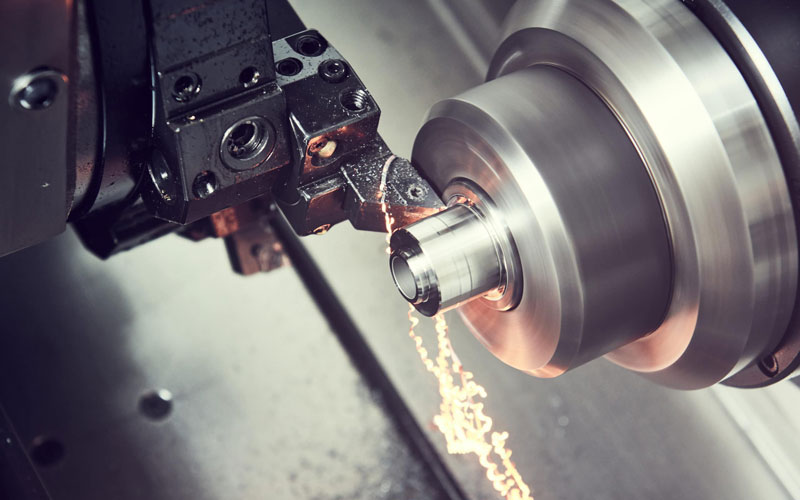

Common Metal Part Machining Methods

Metal Parts Machining Methods Comparison:

Machining Method | Features | Applications | Tolerances | Surface Finish | Cost |

CNC Turning | Ideal for cylindrical parts, high precision, efficient production | Mechanical parts, automotive components | ±0.01 mm | Smooth (Ra 0.8-1.6 µm) | Medium |

CNC Milling | Multi-axis machining for complex geometries | Aerospace, molds, mechanical components | ±0.01 mm | High quality (Ra 0.8-3.2 µm) | Medium |

3D Printing | Layer-by-layer manufacturing, suitable for prototypes and complex parts | Prototypes, complex geometries | ±0.01 mm | Adjustable, rough to smooth | Low to medium |

Rapid Prototyping | Quick production for testing and prototyping | Design iterations, test samples | ±0.01 mm | Variable | Low |

Sheet Metal Fabrication | Suitable for large, thin parts with bending and cutting | Enclosures, brackets, panels | ±0.5 mm | Variable | Low |

Casting | Mass production of complex shapes, suitable for durable parts | Engine housings, mechanical components | ±0.01 mm | Medium (Ra 6.3-12.5 µm) | Low |

Brief Explanation of Cost Comparison:

- CNC Turning and CNC Milling:

High precision, moderate cost, suitable for high-demand precision machining. - 3D Printing:

Ideal for small batch production and complex parts, low upfront cost but higher for mass production. - Rapid Prototyping:

Lowest cost, ideal for quickly validating design concepts and prototypes. - Sheet Metal Fabrication:

Good for large-sized or thin parts, lower cost, efficient for mass production. - Casting:

Best for large quantities and complex shapes, lowest per-unit cost, though initial tooling can be expensive.

- CNC Turning and CNC Milling:

This comparison helps you choose the most suitable machining method based on your project’s requirements and optimize your costs accordingly.

Why choose Allied Metal for custom metal parts machining?

From design to production, we take care of every step to ensure quality and consistency.

We have state-of-the-art CNC equipment and 3D printing technology.

We are experienced in working with a wide range of metal materials.

Tailor the process to your project needs to optimize cost, material and performance.

FAQ

Consider factors like strength, corrosion resistance, weight, and cost. We can help guide you based on your specific requirements.

CNC milling is ideal for complex shapes, while 3D printing works well for rapid prototyping.

Yes, we offer flexible production volumes, from single prototypes to large-scale production.

We use advanced CNC machines with tight tolerances and conduct thorough quality checks on every part.