Editor’s Note: Last updated on October 31, 2025 by Lucy

Over 25 years of operating everything from old manual machines to the latest five-axis CNC machining centers, I’ve come to understand one thing: the control system is the brain of the factory. It determines whether the shop runs smoothly or is plagued by constant problems. Below, I’ll share the control systems I’ve used and encountered.

1. What is a CNC systems?

Think of a CNC system as the brain and nervous system of your machine tool. In my 25 years on the shop floor, I’ve come to see it as the difference between a skilled craftsman and a robot – it’s what takes digital designs and turns them into physical parts with incredible precision.

Basically, it’s the computer that reads your CAD files, translates them into machine movements, and controls everything from spindle speed to coolant flow. But here’s what really matters on the factory floor: a good CNC system doesn’t just follow instructions – it helps prevent crashes, optimizes tool paths, and keeps your machines running when you need them most.

I’ve seen shops waste thousands on fancy machines with poorly matched controls. The truth is, the CNC system determines how easily your operators can work, how quickly you can set up new jobs, and ultimately, how much money you make.

2. The Role of CNC Systems.

The main roles of a CNC system include:

- Improving machining accuracy: Machining of complex shapes is achieved through precise control of tool position.

- Improve production efficiency: automated operation reduces manual intervention and speeds up production.

- Simplify the operation process: users only need to enter the program, the system can complete the entire machining process.

- Reduce human error: through the computer program control, reduce the possibility of operating errors.

3. Top 10 CNC Systems

1. Fanuc

Country: Japan

Cost: Medium to high price

Applicable industries: Widely used in automotive, aerospace, mold making, etc.

Features: the world’s leading manufacturer of CNC systems, known for high precision and reliability, suitable for a variety of machine tools.

2. Siemens

Country: Germany

Cost: medium-high price

Applicable industries: industrial automation, energy, manufacturing

Features: provide comprehensive CNC solutions, intelligent and digital design, suitable for a variety of complex applications.

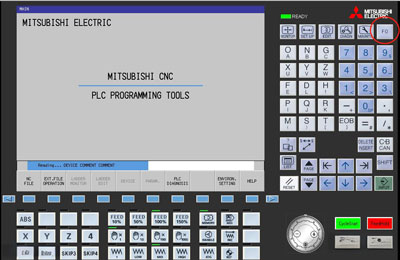

3. Mitsubishi

Country: Japan

Cost: Medium price point

Applicable industries: small and medium-sized enterprises, especially machining and manufacturing industries

Features: High performance and user-friendly interface, easy to operate, suitable for beginners.

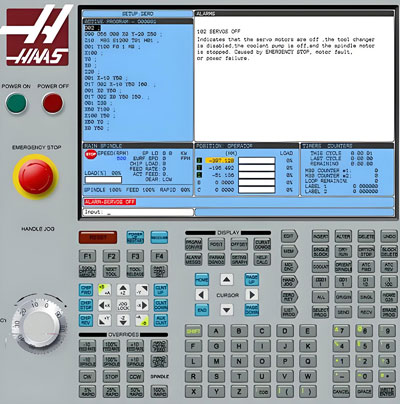

4. Haas Automation

Country: United States

Cost: Low to mid-priced

Industry: Small manufacturers, educational institutions

Features: Known for its cost-effective pricing, it offers a wide range of machine tools and CNCs for those with limited budgets.

5. GSK

Country: China

Cost: low

Applicable industries: suitable for most of the domestic manufacturing industry, a variety of machining industry.

Features: Provide economical and practical CNC system to meet the domestic market demand, stable performance.

6. Emco

Country: Austria

Cost: Medium price

Industry: Education and training, machining

Features: Innovative CNC solutions with a special focus on applications in education and training.

7. Okuma

Country: Japan

Cost: Medium to high

Applicable industries: high-end manufacturing, automotive, aerospace

Features: favored for stability and powerful functions, suitable for complex and precision machining.

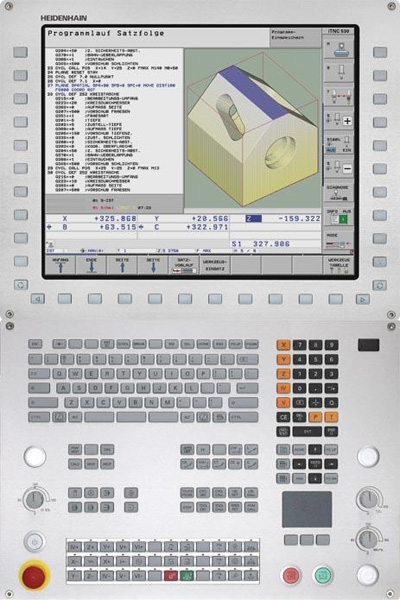

8. Heidenhain

Country: Germany

Cost: Medium-high price

Applicable industries: high-precision machining field, medical equipment

Characteristics: Known for its high precision and quality CNC systems, suitable for stringent machining requirements.

9. Kondia

Country: Spain

Cost: Medium price

Applicable industries: machining, manufacturing

Features: Provides multi-functional CNC system, especially suitable for milling and turning machining.

10. Fagor Automation

Country: Spain

Cost: Medium price point

Industry: Manufacturing, especially in the European market

Features: Provides flexible CNC solutions for a wide range of machining needs, cost-effective.

4. How to Choose the Right System for Your Shop?

For Job Shops Doing Everything

Start with Haas or Fanuc – they’re the Swiss Army knives of CNC controls. Easy to find operators, good support, and they handle 90% of work perfectly.

For High-Precision Work

Look at Heidenhain or Siemens – when tolerances under 0.01mm are everyday work, these systems deliver.

For Production Environments

Fanuc or Mitsubishi – set it and forget it reliability with minimal surprises.

For Specialized Applications

NUM or Okuma – when you need controls built for specific processes like grinding or large-part machining.

My Personal Recommendations

- For New Shops:

Start with Haas controls. They’re affordable, well-supported, and your operators will be productive quickly.

- For Growing Shops:

Add Fanuc or Mitsubishi for your production workhorses. The reliability will save you money in the long run.

- For Advanced Shops:

Invest in Siemens or Heidenhain for your complex work. The programming power pays for itself on difficult jobs.

5. Summary

The best CNC system is the one that makes you money reliably. Don’t get caught up in specs – think about uptime, training costs, and support.

Among the many excellent CNC systems, understanding their characteristics and advantages will help companies make more informed choices. We hope that this article will provide you with valuable information to help your production and manufacturing efforts.