EDITOR'S NOTE: Updated on October 14, 2025,We've added a detailed case study showing how bridge tooling helped a long-term automotive client accelerate their product launch while reducing upfront investment.

Need production-quality parts faster than full-scale tooling allows? Waiting for months can delay market entry or critical product testing. Bridge tooling offers a smart, accelerated solution.

Bridge tooling is an interim tooling solution, often made from softer materials like aluminum, designed to produce functional parts in low to medium volumes quickly. It effectively "bridges" the gap between initial prototyping and long-lead-time, high-volume production tooling.

David, I know in your role developing industrial automation systems, getting new designs from the drawing board to functional testing and then to market swiftly is always a top priority. Sometimes, that leap from a few prototypes to commissioning full-scale production tooling can feel enormous, not just in terms of weeks or months, but also in upfront investment. This is precisely where a strategic approach like bridge tooling becomes incredibly valuable. It's a method we've refined at Allied Metal, and it has consistently helped many of my clients navigate this critical intermediate phase with greater speed and cost-efficiency.

Let's explore what bridge tooling really means for your projects.

Case Study: Bridge Tooling for Automotive Cooling System Component

Wondering how bridge tooling performs in real-world automotive applications? This case study demonstrates how strategic tooling selection helped a major German automotive supplier accelerate their product launch while managing risk.

We delivered a bridge tooling solution that enabled a long-standing automotive client to produce 8,000 functional cooling system components in just 7 weeks—65% faster than their traditional steel tooling timeline—while reducing initial tooling investment by 72%.

For over six years, we've collaborated with this premium German automotive supplier on various under-hood components. Their latest project involved a complex engine cooling module with challenging requirements:

- Material: Glass-filled nylon (PA6-GF30)

- Annual Volume: 15,000 units initially, with potential growth to 45,000

- Critical Features: Multiple snap fits, fluid channels, and mounting points

- Timeline: Needed parts for vehicle testing and early production within 10 weeks

The Challenge: Traditional production tooling would have required:

- 20-week lead time for hardened steel mold

- $85,000 initial tooling investment

- High commitment before design validation

- Limited flexibility for potential design changes

Our Bridge Tooling Solution: We recommended and implemented an aluminum bridge tooling approach with these specifications:

| Parameter | Traditional Steel Tooling | Bridge Tooling Solution | Improvement |

|---|---|---|---|

| Tool Material | H13 hardened steel | 7075 aircraft aluminum | - |

| Lead Time | 20 weeks | 7 weeks | 65% faster |

| Initial Cost | $85,000 | $24,000 | 72% savings |

| Cavities | 2 | 1 | - |

| Cycle Time | 45 seconds | 52 seconds | +15% |

| Parts Delivered | 0 (in 20 weeks) | 8,000 (in 7 weeks) | Immediate production |

Implementation Details:

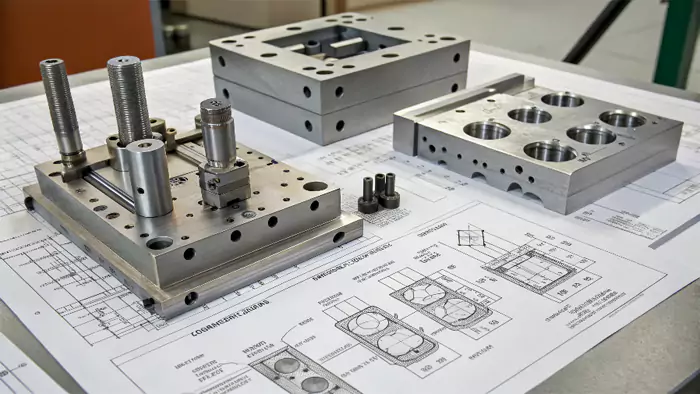

- Tool Design: Single-cavity mold with simplified cooling channels

- Manufacturing Process: High-speed CNC machining with EDM for delicate features

- Quality Standards: Full dimensional inspection and material certification

- Production Capacity: 500-700 parts per week

- Tool Life: Estimated 25,000-30,000 shots before significant maintenance

Key Benefits Realized:

- Accelerated Timeline: The client received first articles for testing within 4 weeks and full production quantities by week 7

- Risk Mitigation: Design validation with production-intent materials before committing to expensive steel tooling

- Market Testing: Ability to supply early adopters and gauge actual demand

- Design Flexibility: Made three minor design revisions during the bridge production phase with minimal cost impact

Results: The bridge tooling approach allowed the client to:

- Begin vehicle testing 13 weeks earlier than planned

- Secure two major customer contracts using actual production parts

- Identify and correct two design issues that would have been costly to fix in steel tooling

- Confidently proceed with $125,000 steel tooling investment based on validated market demand

The production manager noted: "The bridge tooling strategy gave us the confidence to move forward with our steel tooling investment. Having real production parts in hand for customer demonstrations and testing was invaluable—it turned speculative conversations into firm orders."

This case demonstrates how bridge tooling serves as more than just a temporary solution; it's a strategic tool for de-risking product launches, validating designs, and optimizing capital allocation in the automotive sector.

What is the primary purpose of bridge tooling?

Launching a new component carries inherent risks. Committing to expensive, hardened steel production tools too early can be a costly gamble if designs change. Bridge tooling helps validate your design and test the market before that large investment.

The main purpose of bridge tooling is to enable quicker production of end-use quality parts in low to medium volumes. This allows for design validation, market testing, and even early revenue generation while full-scale production tooling is being manufactured.

The real beauty of bridge tooling lies in its ability to significantly de-risk your product development cycle.

When you're designing complex mechanical components for industrial automation, you need certainty before committing to high-volume manufacturing. Bridge tooling serves several key purposes here.

First, it allows you to get functional parts, often made from production-intent materials, into your hands and into testing environments much faster than traditional tooling would allow. This means you can conduct real-world performance tests1, gather crucial feedback, and make necessary design iterations based on tangible results.

Second, it’s an excellent way to test the market waters. You can produce a pilot run of several hundred or a few thousand parts to gauge customer interest, secure initial orders, or supply early adopters.

This feedback and early sales can be invaluable in refining your forecasts and justifying the investment in subsequent mass production tooling. It helps you make data-driven decisions2, ensuring the final product truly meets the demands of your industry.

When is using bridge tooling the right strategic move?

Facing tight project deadlines or uncertain initial sales volumes for a new product? Standard production tooling is often too slow and expensive for these situations. Bridge tooling offers a flexible, faster, and more cost-effective path for these exact scenarios.

You should use bridge tooling when you need parts significantly faster than production tooling allows, for pilot production runs, for market testing phases, or when initial order volumes are uncertain. It is also very useful if minor design changes are still anticipated.

Knowing the right time to opt for bridge tooling can give your company a significant competitive advantage. It's not just about getting parts; it's about strategic timing and resource management. Here are some common situations where I've seen bridge tooling make a huge difference for engineers:

Accelerating Time-to-Market

If your project has an aggressive timeline, bridge tooling can drastically shorten the period between design finalization and having saleable products. While your high-volume production tool might take 10-16 weeks to build, a bridge tool can often be ready in just 3-6 weeks. This speed can be crucial for meeting launch dates or trade show commitments.

Managing Uncertain Demand

For a new component in your automation systems, you might have promising forecasts, but actual initial demand can be hard to predict. Investing heavily in production tooling for uncertain volumes is risky. Bridge tooling allows you to start production with a lower initial investment, matching output to actual early orders.

Iterative Design Refinement

Even after prototyping, you might want the ability to make small design tweaks based on initial field tests or customer feedback. Bridge tools are typically less complex and less expensive to modify than hardened steel production tools, offering more flexibility for late-stage refinements.

Low to Medium Volume Production Needs

Sometimes a product is specialized, and the total lifetime volume might only be a few thousand to tens of thousands of units. In such cases, a well-made aluminum bridge tool might even serve as the production tool for the entire product lifecycle, saving considerable cost compared to steel tooling. I recall a client needing 5,000 specialized enclosures annually; a bridge tool was the perfect, cost-effective solution for them.

What does the general tooling process in manufacturing involve?

Need a clearer picture of how manufacturing tools are actually created? The tooling process can seem intricate, directly impacting your project's lead times and costs. I'll outline the typical steps involved in bringing these essential manufacturing aids to life.

The tooling process in manufacturing encompasses the design, engineering, and fabrication of tools like molds, dies, or fixtures. These custom-made instruments are then used to produce parts consistently through various manufacturing methods like injection molding or stamping.

Understanding the general tooling process helps appreciate why different tooling strategies exist. Whether it's a bridge tool or a high-volume production tool, several core stages are involved, though the complexity and materials differ.

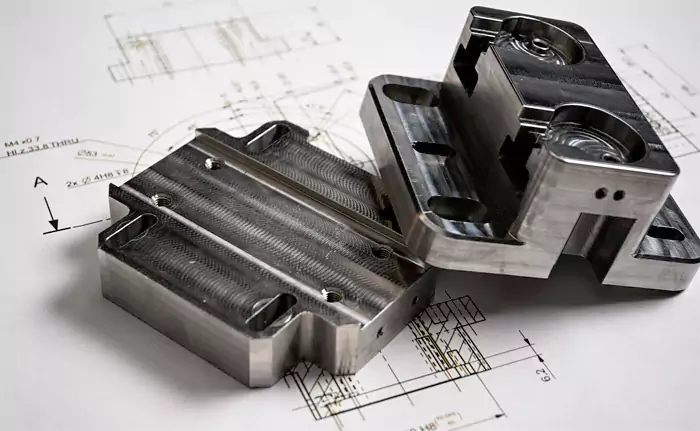

First, there's Tool Design. Based on your final part CAD model, engineers like me design the tool itself. This includes features like cores, cavities, gates, runners, ejector systems for molds, or the punches and dies for stamping. We consider material flow, cooling, and part ejection.

Next is Tool Material Selection. For bridge tools, we often use aircraft-grade aluminum because it's easier and faster to machine, and it offers good thermal conductivity for processes like injection molding. For long-run production tools, hardened steels like P20 or H13 are common for their durability.

Then comes the actual Tool Manufacturing. This involves precision CNC machining of the tool components, EDM (Electrical Discharge Machining) for intricate features, and surface treatments or polishing.

After fabrication, the components are Assembled, and the tool undergoes Tryout and Spotting. We run initial samples (First Shots) to test its functionality, check part dimensions, and make any necessary adjustments to ensure it produces parts to your exact specifications.

Finally, there's Qualification and Approval. You would review sample parts, and once approved, the tool is ready for production. This entire sequence, especially for complex steel tools for industrial automation parts, can take many weeks or even months. This is why bridge tooling, by simplifying aspects of this process and using faster-to-machine materials, offers such a significant time saving.

What are the different types of tooling used in manufacturing?

Unsure about the various tooling options available for your components? Choosing an inappropriate type can negatively affect your budget, timeline, and part quality. Let's explore some common tooling categories to help clarify your choices.

Tooling types are diverse and correspond to specific manufacturing processes. Common examples include injection molds for plastics, stamping dies for sheet metal, extrusion dies for profiles, casting patterns for metal parts, and various jigs and fixtures for assembly or inspection.

In manufacturing, "tooling" is a broad term, but it always refers to custom-made devices that shape or help produce your parts. The type of tooling directly relates to the manufacturing process and the intended production volume. Here’s a simplified breakdown:

-

Prototype Tooling: This is used for creating a very small number of parts, primarily for design verification, fit checks, or functional prototypes3. It can range from 3D printed molds or inserts for basic molding to simple, single-cavity tools made from inexpensive materials. Speed and low cost are the main drivers here, not tool longevity.

-

Bridge Tooling: As we've discussed, this is your intermediate solution. It’s more robust than prototype tooling, capable of producing hundreds to tens of thousands of parts. For injection molding, these are often made from aluminum. They provide production-quality parts much faster and at a lower cost than full production tooling, ideal for market entry or ramp-up phases. This is often a sweet spot for components of new automation systems.

-

Production Tooling (Hard Tooling): This is designed for high-volume manufacturing, often intended to produce hundreds of thousands or even millions of parts over its lifespan. These tools are typically made from hardened steel and are built for maximum durability and efficiency. They represent the largest investment in terms of cost and lead time but offer the lowest per-part cost at high volumes.

For the parts you design, which might involve plastics or metals, you'll encounter injection molds, die casting dies, or stamping dies. Each of these can be created as prototype, bridge, or production tooling, depending on the specific needs of your project stage. At Allied Metal, we always discuss these options to ensure you get the most effective tooling strategy.

How is "bridging" understood in a manufacturing context?

The term "bridging" can seem quite broad when you hear it. Misunderstanding its specific meaning within a manufacturing context can lead to confusion. I'll explain how "bridging" typically relates to production strategies and sometimes, manufacturing challenges.

In manufacturing strategy, "bridging" often refers to solutions like bridge tooling that fill a critical gap—be it in time, volume, or cost—between product development stages. Separately, it can also describe specific physical defects in certain processes like 3D printing.

The concept of "bridging" in manufacturing, especially when we're talking about product development and production scale-up, is really about creating a connection across a gap. While the term can sometimes refer to a physical defect – for instance, in 3D printing when material sags incorrectly across an unsupported span, or incomplete filling in an injection molded part – the more strategic meaning relates directly to the idea of bridge tooling.

In this strategic sense, "bridging" means:

- Bridging Time: This is about closing the time gap between having a finalized design and getting your product to market. Full production tooling takes time to build. Bridge tooling gets you parts much sooner, allowing you to launch or test while the main tooling is in progress.

- Bridging Volume: It addresses the need for quantities that are too high for prototyping methods but too low to immediately justify expensive high-volume tooling. It’s perfect for those initial production runs.

- Bridging Investment: It allows your company to test a product's market viability and generate initial revenue with a smaller tooling investment before committing to the significantly higher cost of hardened steel production tools.

Essentially, bridge tooling is the primary mechanism for this strategic "bridging." It’s a proactive way to manage the transition from low-volume, early-stage development to efficient, high-volume manufacturing, minimizing risks and optimizing resource allocation along the way. This is a core part of the value we bring at Allied Metal, helping companies navigate these transitions smoothly.

What kind of software aids the "bridge" manufacturing phase?

Wondering if there's specific "bridge software" to support these interim manufacturing strategies? Efficiently managing data and processes is absolutely key when speed is essential. Let's look at the types of software crucial for effective bridge tooling and rapid production.

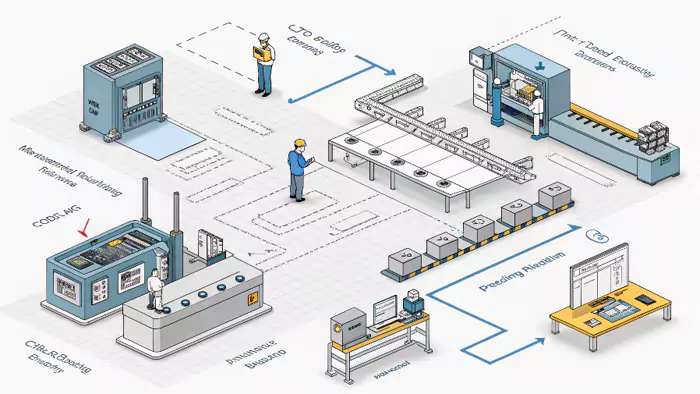

While a dedicated "bridge software" category doesn't quite exist, a combination of CAD, CAM, CAE (simulation), and project management software is vital for successful bridge tooling. These tools enable rapid tool design, quick toolpath generation, process simulation, and efficient collaboration.

It's a common question whether specialized software exists for this phase. While you won't find a software package explicitly labeled "bridge software," a suite of sophisticated software tools is absolutely fundamental to making bridge tooling a fast and effective strategy. These are the digital enablers that allow us, as a manufacturing partner, to deliver on the promise of speed and quality.

Key software categories include:

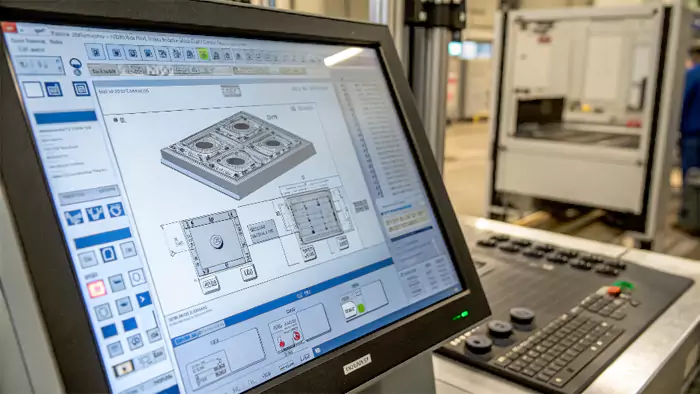

- CAD (Computer-Aided Design) Software: This is where it all starts. We use your precise digital drawings, typically from your CAD system, as the foundation. We then use our CAD software to design the bridge tool itself – the mold cavities, cores, and overall structure – rapidly and accurately. Parametric features in modern CAD allow for quick modifications if needed.

- CAM (Computer-Aided Manufacturing) Software: Once the bridge tool is designed, CAM software takes over to generate the CNC machine toolpaths required to cut the aluminum or other tool materials. Advanced CAM systems with features like tool path optimization are crucial for machining these tools quickly and efficiently.

- CAE (Computer-Aided Engineering) or Simulation Software: For more complex parts or processes like injection molding, we often use simulation software. This allows us to predict things like material flow, cooling patterns, and potential defects before any metal is cut for the bridge tool. This minimizes trial-and-error and speeds up the tool qualification process.

- Project Management and Collaboration Software: To ensure quick and accurate quotes, manage tight deadlines, and maintain clear communication (while always safeguarding your proprietary designs), robust project management and secure data exchange platforms are essential. These tools help streamline the entire workflow from an initial RFQ to part delivery.

So, it's this integrated digital toolkit, rather than a single "bridge software," that underpins our ability at Allied Metal to deliver high-quality bridge tooling solutions effectively for time-sensitive projects.

Conclusion

Bridge tooling strategically closes the critical gap between initial prototyping and full-scale production, offering vital speed and cost-effectiveness for timely market validation and smoother product launches.

-

Exploring the role of real-world performance tests can enhance your approach to product development and ensure better outcomes. ↩

-

Learning about data-driven decisions can empower you to optimize your manufacturing processes and improve product success rates. ↩

-

Learn about the role of functional prototypes in testing and refining designs before full-scale production. ↩