Table of Contents:

What is G-Code: Definitions, Uses, Directives & Free G-Code Editors

- December 12, 2024

- Tony

1. Overview

What is a G-Code?

G-code (also known as “geometric code”) is a programming language used to control CNC machine tools. It consists of a series of precise instructions that control the motion, speed and machining path of the machine.

As a standardized language, G code is used in a wide variety of automated manufacturing equipment to perform operations ranging from simple cutting to complex 3D engraving.

What is the purpose of G-Code?

The main purpose of g-code is to precisely control the machine tool to perform a specific machining task through a computer program.

Through the use of g code, it is possible to realize the functions of fast positioning, inverse circular interpolation, smooth circular interpolation, intermediate point arc interpolation, radius programming, jump machining, etc.

Importance of G-Code in CNC machine tools

In modern manufacturing, CNC machine tools have become the core tool for improving productivity and machining accuracy. Code is the “language” of CNC machine tools, without which the machine cannot perform any operation.

The quality of CNC programming directly affects machining accuracy, productivity and the quality of the final product. Therefore, mastering g code is crucial for operators and programmers.

2. Basic structure of G-code

G-code is composed of several key components, each serving a specific function:

- Alphabets: G code commands begin with the letter “G” followed by a number. Each number represents a different type of command (e.g., G0, G1, etc.). Other letters such as M, T, and F control additional machine functions.

- Numbers: The digits following each command specify particular actions. For example, G0 indicates rapid positioning, while G1 refers to linear interpolation.

- Instructions: These guide the machine tool to perform tasks like moving to a specific position, changing speed, or altering the machining mode.

3. Common G-code instructions

There are many G code instructions, each with its own specific function. The following are the common instructions:

Motion Control Commands

- G00 – Rapid Positioning

- G02 – Clockwise circular interpolation

- G03 – Counterclockwise Interpolation

- G04 – Dwell Time

- G28 – Return to reference point

Feed rate control

- G94 – Feed Rate (mm/min)

- G95 – Feed rate (mm/rev)

Coordinate system control

- G17 – XY plane

- G18 – XZ plane

- G19 – YZ plane

- G54-G59 – Workpiece coordinate system

Other commands

- G20 – Imperial units

- G21 – Metric units

- G40 – Tool radius compensation off

- G41/G42 – tool radius compensation left/right

- M03/M04 – Spindle rotation clockwise/counterclockwise

- M05 – Spindle stop

- M08 – Coolant on

- M09 – Coolant Off

4. G-code how to control the movement of CNC machine tools

Through G code, machine tool movement is precisely controlled by specifying coordinate positions, cutting paths, and travel speeds. Specifically:

- Coordinate Axis Control: Commands can define the machine tool’s movement along the X, Y, and Z axes. For example, “G0 X100 Y50” moves the machine to 100mm on the X-axis and 50mm on the Y-axis.

- Speed Control: The feed rate (F) and spindle speed (S) are specified to control cutting speeds during machining.

- Motion Path: G-code dictates whether the machine follows a straight line or a circular arc, ensuring the tool moves along a set trajectory for accurate results.

5. Which machines use G-code

G-code is widely used in the field of CNC machining, mainly for the following types of CNC machines:

Milling machine:

Used to perform precision CNC milling operations, capable of efficiently removing excess material and realizing customized processing of complex shapes.

Lathe:

Suitable for processing rotating parts, widely used in automotive and aerospace industries, capable of meeting high precision requirements for parts.

Drilling Machine:

Specialized for drilling operations, commonly used in the processing of metals and plastics to ensure accuracy and consistency of hole positions.

EDM:

Used for high-precision EDM machining, especially suitable for handling high hardness materials to achieve customized manufacturing of complex shapes.

3D printers:

Some high-end 3D printers use G-code for print path control, enabling more possibilities in customized manufacturing.

6. The difference between G code and M code

In CNC machining, G-code and M-code are both essential, but they serve different purposes:

- G-code controls the movement path, speed, and processing mode of the machine tool during machining.

- M-code manages the machine’s functional operations, such as controlling the spindle or coolant system.

M-code handles the “actions” of the machine, while G-code controls its “path.”

Both codes often work together in a CNC program to ensure the machine performs its tasks efficiently.

7. G-code programming techniques

Writing efficient G code requires both technical skill and attention to key programming techniques:

- Eliminate Redundancy: Avoid repeating instructions to improve program efficiency.

- Optimize Path Planning: Plan cutting paths carefully to minimize idle time and unnecessary stops during complex machining tasks.

- Use Macro Variables: Incorporating macro variables enhances flexibility, especially in mass production.

- Ensure Precision: Accurate execution of each G code is crucial to prevent errors and workpiece failure.

8. Free G-code Editor Providers

If you’re looking for free G code editors, several providers offer powerful tools for CNC programming without any cost. Some of the popular options include:

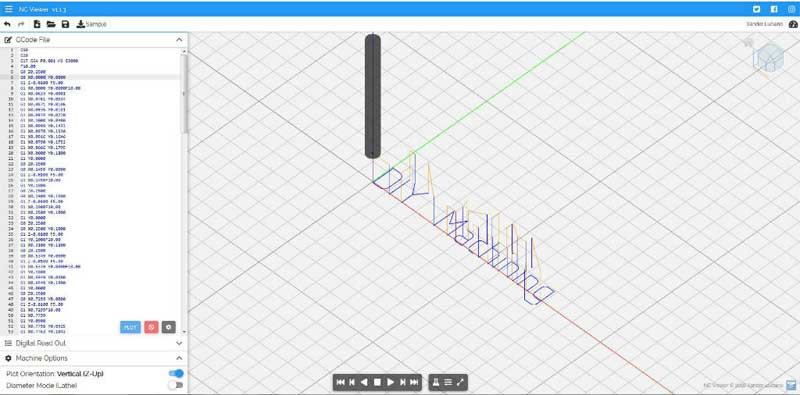

NC Viewer

Web-based G-code viewer and editor, easy to use, click to enter the NC Viewer official website allows you to preview and edit code online.

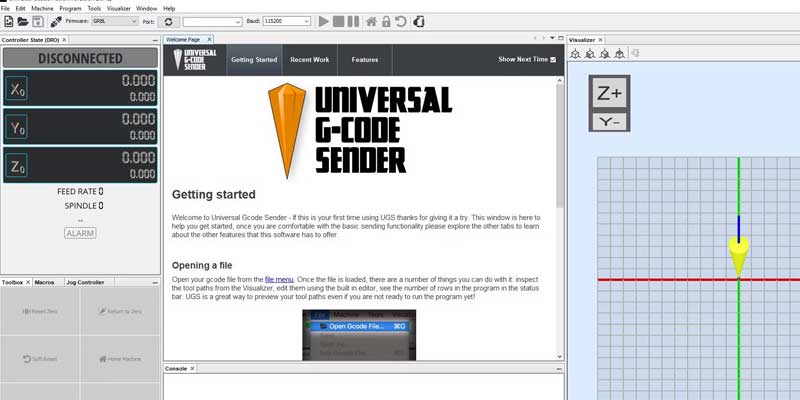

Universal Gcode Sender (UGS)

An open-source G-code sender and editor designed for CNC machines, compatible with various machines and controllers.

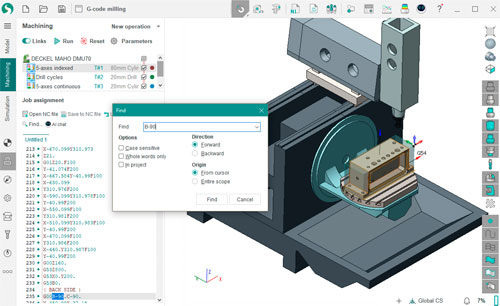

G-code Simulator

A free software tool that allows you to simulate, generate, and edit G code before running it on your CNC machine.

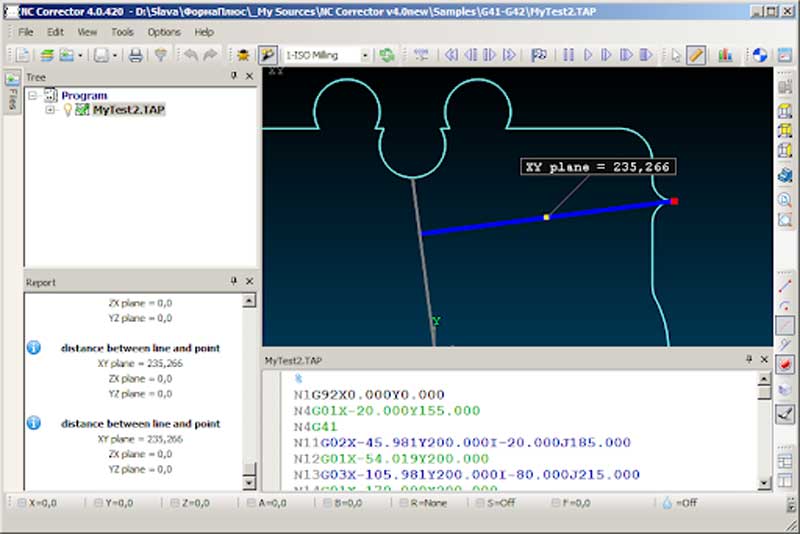

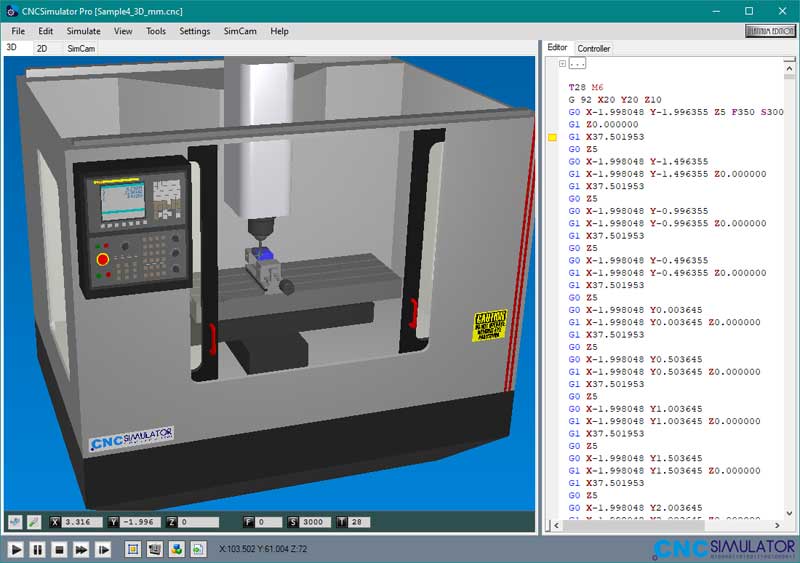

CNC Simulator Pro

A free version of a CNC simulator that lets you write, edit, and simulate G code programs.

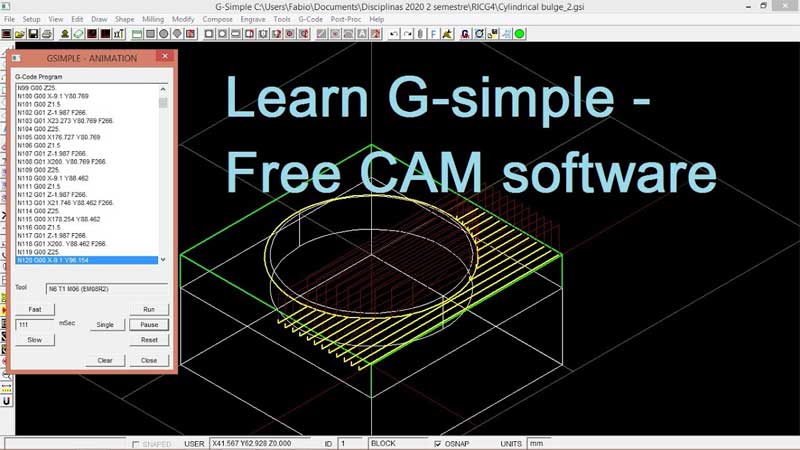

G-Simple

An easy to use G code generator for beginners that provides basic editing and generation functions and supports a wide range of CNC machines.

These tools can help you improve your CNC programming without the need for costly software.

9. Common G-code Errors and Solutions

- Incorrect Coordinates: Inaccurate coordinates can cause tool collisions or machining errors.

Solution: Double-check coordinate values in the G-code.

- Missing Pause Instructions: Missing pause or tool change instructions can disrupt the operation sequence.

Solution: Ensure proper pauses between operations.

- Incorrect Units: Using the wrong units (imperial or metric) can lead to inaccurate dimensions.

Solution: Verify G20 (imperial) and G21 (metric) instructions.

- Instruction Conflicts: Conflicting G codes can cause incorrect machine actions.

Solution: Ensure all instructions are logically compatible.